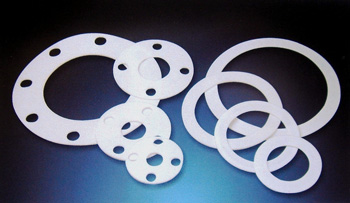

High quality PTFE seals gasket

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 200000 pcs per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Material: | Others |

| Material: | PTFE |

| Place of Origin: | Ningbo china |

| szie: | for customer request |

| Color: | White,Blue,Black etc |

| Temperature: | -180℃+260℃ |

| Style: | seals |

| Package: | plastic&carton |

| Shape: | Flat Gasket |

| Delivery Detail: | within 25 days after we receive clents' order or negotiations |

| Density: | 2.1-2.3 g/cm³ |

| Production Capacity: | 200000 pcs per Month |

| Packing: | PP Bag&carton |

| Delivery Date: | 25days |

Product Description

PTFE Seals Gasket

PTFE is a thermoplastic polymer, which is a white solid at room temperature, with a density of about 2200 kg/m3. According to DuPont, its melting point is 600 K (327 °C; 620 °F). Its mechanical properties degrade gradually at temperatures above 194 K (79 °C; 110 °F). PTFE gains its properties from the aggregate effect of carbon-fluorine bonds, as do all fluorocarbons. The only chemicals known to affect these carbon-fluorine bonds are certain alkali metals and most highly reactive fluorinating agents.

The coefficient of friction of plastics is usually measured against polished steel. PTFE's coefficient of friction is 0.05 to 0.10, which is the third-lowest of any known solid material (BAM being the first, with a coefficient of friction of 0.02; diamond-like carbon being second-lowest at 0.05). PTFE's resistance to van der Waals forces means that it is the only known surface to which a gecko cannot stick.

PTFE has excellent dielectric properties. This is especially true at high radio frequencies, making it suitable for use as an insulator in cables and connector assemblies and as a material for printed circuit boards used at microwave frequencies. Combined with its high melting temperature, this makes it the material of choice as a high-performance substitute for the weaker and lower melting point polyethylene that is commonly used in low-cost applications.

Because of its chemical inertness, PTFE cannot be cross-linked like an elastomer. Therefore, it has no "memory" and is subject to creep. This is advantageous when used as a seal, because the material creeps a small amount to conform to the mating surface. However, to keep the seal from creeping too much, fillers are used, which can also improve wear resistance and reduce friction. Sometimes, metal springs apply continuous force to PTFE seals to give good contact, while permitting a beneficially low percentage of creep.

Product Structure:

shaped, sectioning type, cut PTFE gaskets from the outside to the inner wall, applicable to the low pressure condition, economic type.

shaped, machining (square), processed by mechanical turning of PTFE sheet, suitable for medium and high pressure conditions.

shaped, folding type, processed by wrapping and caking of PTFE belt, generally used when the diameter is greater than 200mm

Product Applications:

Since the traditional cutting gasket can not meet the requirements of the chemically resistant mediums, special composite design of PTFE jacketed gasket is the ideal solution. It applies to pollution-free occasions, like food and pharmaceutical industries, and can effectively solve those intractable media such as the medium alkali, low-temperature fluids, oxygen, chlorine, etc.

1.PTFE is a kind of absolutely real chemically resistant medium;

2.It can be used at the temperature of -200 ~ +250 ℃ as long as the filler is applicable;

3.It is of corresponding mechanical strength according to different fillers;

4.Recommended working pressure: ≤ 4 Mpa.