High Capacity Animal Feed Hammer Mill

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 220 Set/Sets / Month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Trading Company |

| Main Products: | Animal Feed Plant, Chaff Cutter, Mixer, Hammer Mill, 9ht Mini Feed Mill |

Product Detail

| Model No.: | SFSP56*40 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Derry |

| Hammers(pcs): | 40 |

| Capacity(T/H): | 5-7 |

| Speed(r/min): | 2950 |

| Diameter Of Sieve: | 2-12mm |

| Gringding Chamber: | water drop |

| Spare Part: | Hammer ,Sieve |

| Color: | Yellow ,White,Gray |

| Raw Material: | Grain,Wheat,Corn etc |

| Auxiliary equipment: | feeder, blower and air lock |

| Material: | Carbon steel/Stainless steel |

| Production Capacity: | 220 Set/Sets / Month |

| Packing: | plywood case |

| Delivery Date: | 7- 10 working days |

Product Description

High Capacity Animal Feed Hammer Mill

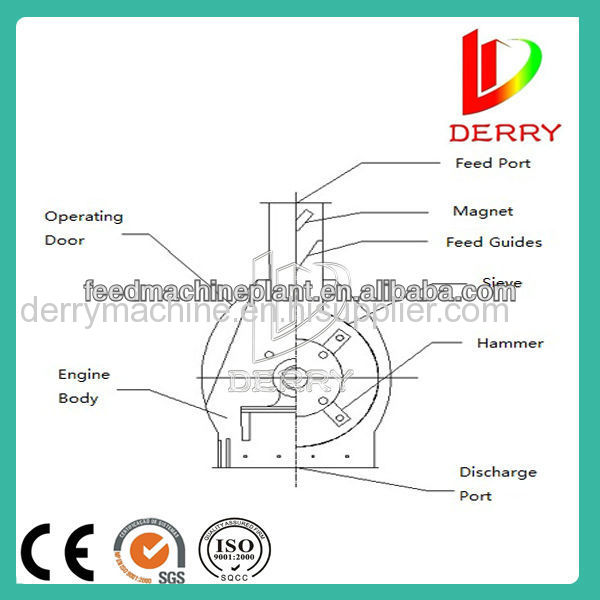

The Introduction:

crush room at the bottom of the use of two-hit designed to increase production by more than 15%,to crush a more uniform size

room for the water drop hammer mill,to elimination of circulation and increase output

through the adjustment of screener space,to achieve coarse or fine crush,so live up to a dual-purpose machine

mill rotor balancing by check,equipment operation less vibration,less noise,more stable

vacuum melting and hardening the surface of hammer pin,plate with high-quality carbon structural steel manufacturing,to extend the service life,reduce the consumption of parts

direct drive,a new snake-coupling spring,compensation,to avoid bearing have a fever

adopt of imported high-quality bearings,long life and smooth operation

impeller feedre equipped with feed conversion and screw conveyor feed speed and other forms of feeder

The Technical Parameter:

Model | SFSP56*36 | SFSP56*40 | SFSP708*40 | SFSP112*30 | SFSP112*40 | SFSP112*60 |

Power (kw) | 22 | 37 | 55 | 75/90 | 110/132 | 160/200 |

Capacity (T/H) | 4-5 | 5-7 | 7-10 | 12-15 | 25-35 | 38-50 |

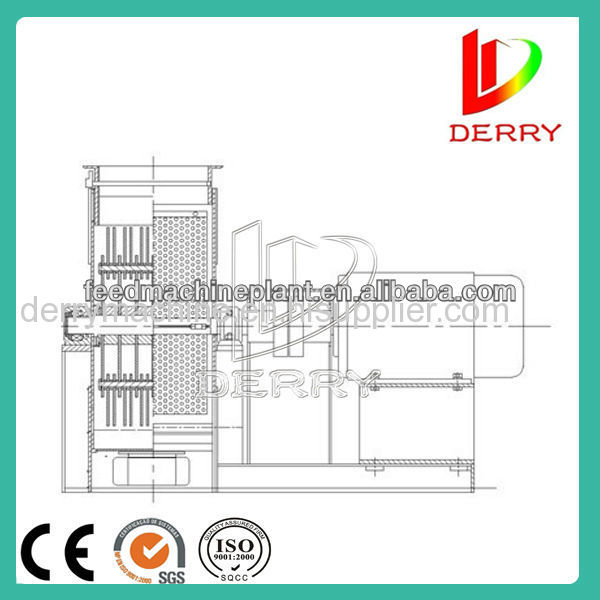

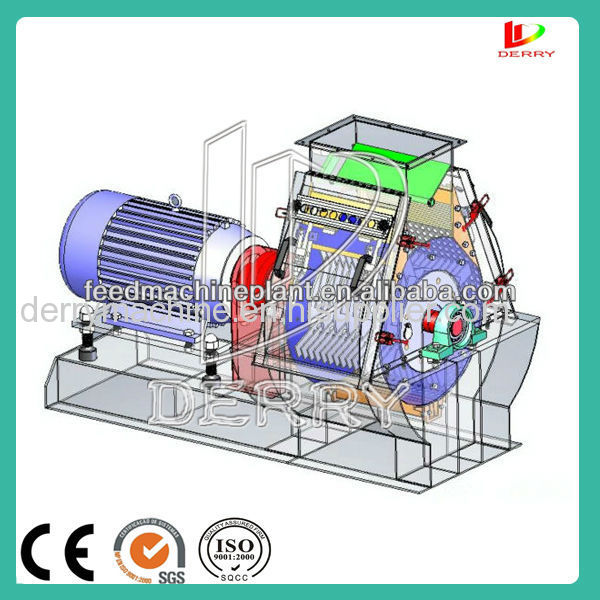

Photos of Animal Feed Hammer Mill :

If you are insterested in our machines, pls contact with us and tell us the following questions :

1.The capacity you need ?

2.Your raw material ?

Our engineer will design it according to your requirement .