Multi-function Fruit Peeling Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Potato Chips Plant, French Fries Making Machine, Banana Chips Machine |

Product Detail

| Model No.: | AMS-6GXD-13 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Acceptable fruit dia.: | 40-100mm |

| Acceptable fruit height: | 40-120mm |

| Thickness of peeling: | 1-6 mm (can be adjusted) |

| Peeling rate: | ≥96% |

| Power: | 0.6 KW |

| Capacity: | 1200pcs/hour ( adjustable) |

| Weight: | 380kg |

| Dimension: | 1700×855×1700mm |

| Delivery Date: | 1-15days |

Product Description

Multi-function Fruit Peeler Machine Introduction

Our multi-function fruit peeler machine is a kind of industrial fruit processing equipment which is mainly utilized for peeling dozens of ball-shaped fruits as well as vegetables with a dia. of φ40-100 and a height of H40-130. It is the necessary equipment for fruit-vegetable products production, enjoying a wide uses in fruit processing plants, delivery centers of chain supermarkets, and central kitchens, etc.

Multi-function Fruit Peeler Machine Specification Data

|

Multi-function Fruit Peeler Machine Features and Advantages

1. Suitable for various fruits and vegetables, such as oranges, apples, pears, peaches, papayas, pineapples, kiwi fruits, pomegranates, grapefruits, tomatoes, potatoes.

2. Capable of finishing peeling, end cutting, coring, sectioning, separating, and color maintaining of products.

3. Computer control allows its automatic self-adaptive capability, so it is working well for fruits and vegetables of different sizes with different dia. and height, and the thickness of peeling is also adjustable.

4. The fruit peeling machine is manufactured according to EU standards with process control and remote control.

5. During operation, click the touch screen and set the working parameters, and then place the product in the fruit holder, the machine can complete fruits and vegetables peeling automatically.

6. Compared to manual peeling and lye peeling, this machine peeling retains original quality of products, and increases their use value.

7. Three sizes of blades for coring and sectioning are prepared to manage varisized products and products cutting.

8. Pure processing result with no pollution:

♦ Spaces for placing and peeling products are separated to keep operators safe and prevent products from pollution.

♦ The machine spots of lubrication, friction and water drip are also separated from the working chambers, avoiding products to be spoiled.

♦ Automatic cleaning after work ensures no waste residue, so it will not affect the next processing.

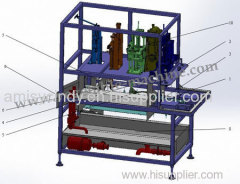

Automatic Fruit Peeler Machine Structure

1. Fruit holder; 2. Infrared positioning light; 3. Circular fruit conveying chain; 4. Fruit fixation fork; 5. Peeler device; 6. End cutter; 7. Coring & sectioning cutter; 8. Color maintaining trough; 9. Multi discharging gates; 10. Automatic height recognition device.

Multi-function Fruit Peeling Machine Working Principle

Let's watch the video of our fruit peeling machine used for peeling oranges to see how it works.

Firstly, before the machine works, the operator should adjust the peeling thickness, set up working parameters and select functions through the operation screen. Then start the machine.

Like the video shows the operator put oranges on the holder one by one, and the infrared positioning light leads each orange to the proper position; then the circular conveying chain put the orange on the fixation fork for peeling. Next the automatic height recognition device presses orange and moves the orange around the fixation fork to let the peeling device to peel the orange automatically. When the peeling device returns to the original position, the peeled oranges are sent to the next processing station; the orange is pressed by the automatic height recognition device and both ends are cut down. There are discharge gates in each processing station; after peeling and cutting ends, the orange flesh, round peels, strip peels are discharged respectively.