Automatic Mushroom Slicing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Potato Chips Plant, French Fries Making Machine, Banana Chips Machine |

Product Detail

| Model No.: | AMS-MGQP-02 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | 0.75 kw |

| Capacity: | 500 kg/h |

| Dimensions: | 1800*700*960 mm |

| Weight: | 165 kg |

| Delivery Date: | 1-15days |

Product Description

Mushroom Slicing Machine Introduction

Mushroom slicing machine is designed to meet the market demand of mushroom processing. The slicer machine is widely used for processing edible mushroom, soft vegetables and fresh kelp. Based on hand-cutting principle, mushroom slicer can cut the material into slices or shreds with regular shape and smooth surface. It is an ideal equipment in vegetable processing industry. Suitable for canned food plant, large restaurant, etc.

Technical Parameters of Mushroom Slicing Machine

|

Features of Mushroom Slicing Machine

1. Mainly stainless steel construction, healthy and durable in use.

2. Advanced design, convenient operation, low energy consumption, high efficiency.

3. The sliced mushroom has uniform thickness, regular shape, smooth cutting surface.

4. Slicing thickness is 6mm and can be customized according to your requirement.

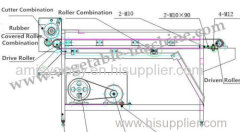

Mushroom Slicing Machine Structure & Working Principle

Mushroom slicer machine consists of frame, cutter combination, switch frame combination, carrier idler, rubber covered roller combination, drive roller, driven roller, and drive system. While the conveyor belt runs, the materials move forward and finally cut into slices or shreds by the cutter combination of the slicer.

Precautions for Using Mushroom Slicer Machine

1. Maintenance of the mushroom cutter machine should be done only when the power is off.

2. Open the shield and add lubricating oil while the cutter machine has worked for 100 hours.

3. Metal or other foreign matter should not be mixed in the vegetables, otherwise the cutter will be damaged.

4. The switch, motor and power line should not be damaged to avoid moisture and water infiltration. To ensure safety, please connect the ground wire where the earthed sign is.

5. If any abnormal phenomena occurs during operation of the mushroom slicer, turn off the power and then check. Eliminate the failure before operation again.

6. Don't wash the mushroom cutting machine while the motor shield is dismantled.

7. Don't operate this mushroom processing equipment while the cutter shield is dismantled.

Tips: We also supply mushroom processing production line which includes bubble washing machine, blanching machine, water cooling machine, sorter, mushroom slicing machine, elevator conveyor, and filling line.

| Model | Reference | Description |

Washing Machine |

Power :1.5kw/380v Capacity:400-800kg/h Dimension:2000*700*1350mm HS code :84386000 | |

|

Power :54.55kw/380v Capacity:400-800kg/h Dimension:3000*1130*1400mm | |

|

Power :1.87kw/380v Capacity:500-1000kg/h Dimension:3000*1300*1400mm | |

|

Power :0.75 kw/380v Capacity:1000-2000kg/h Dimension:3000*1100*1500mm | |

Slicing Machine |

Power :0.75kw/380v Capacity:500kg/h Dimension:1800*700*960mm | |

|

| |

|

| |

|