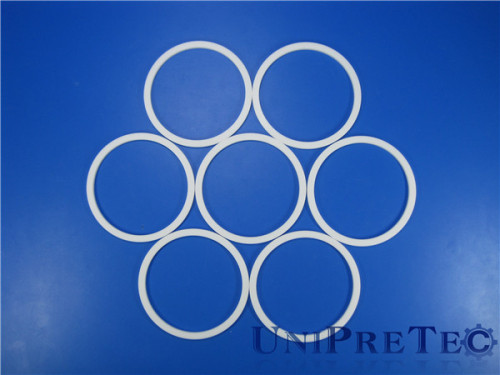

Electrical Insulator 95 Alumina Ceramic Seal Rings

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 30000pcs/year |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Industrial Ceramic, Advanced Ceramic, Technical Ceramic |

Product Detail

| Model No.: | UPT-ALC027 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | UNIPRETEC |

| Material: | Alumina |

| Purity: | 95% |

| Color: | White |

| Density: | 3.65g/cm3 |

| Young's Modulus: | 280Gpa |

| Flexural Strength: | 280Mpa |

| Compressive Strength: | 2000Mpa |

| Thermal Conductivity: | 18-25W/(m•K) |

| Thermal shock resistance: | 220ΔT(C°) |

| Max. Working Temperature: | 1500℃ |

| Production Capacity: | 30000pcs/year |

| Packing: | wooden box / carton box |

| Delivery Date: | 40days |

Product Description

1.Material: Alumina Ceramic, Al2O3 Ceramic, Aluminum Oxide

2.Purity: 95%

3.Color: White

4.Product Feture:

*Good thermal conductivity

*Good strength and hardness

*Good resistance to wear and corrosion

*Temperature resistance up to 1500°C

Alumina (aluminum oxide) is the most important, widely used and cost effective oxide ceramic material. The technical alumina ceramics contain at least 80% of aluminum oxide (AL2O3). Small amounts of silica (SiO2), magnesia (MgO) and zirconia (ZrO2) may be added to alumina ceramics. Addition of zirconia to alumina ceramic results in considerable increase of the material fracture toughness.

Typical Alumina characteristics include:

*High mechanical strength (flexural strength) and hardness;

*High wear resistance;

*High resistance to chemical attacks of strong acids and alkali even at high temperatures;

*High stiffness;

*Excellent insulating properties;

*Low coefficient of thermal expansion;

*Good fracture toughness;

*Good thermal conductivity;

*Good biocompatibility.

| Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

| Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

| Color | - | white | ivory | white | gray | white | white |

| Density | g/cm3 | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

| Flexural Strength @R.T. | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

| Compressive Strength @R.T. | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

| Thermal Conductivity @R.T. | W/(m*k) | 18-25 | 30 | 2.2 | 25 | 20 | 1.7 |

| Thermal shock resistance | Δ(℃) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

| Max. Working Temperature @R.T. | ℃ | 1500 | 1700 | 850 | 1200 | 960 | 800 |

| Volume Resistivity @R.T. | Ω*cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

| Dielectric Constant (1 MHz @R.T. ) | - | 9.5 | 9.8 | 26 | 8.2 | 4.08 | 6.02 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

Application of Al2O3:

Aluminum ceramics are widely used in electronics and electrical engineering, metallurgical processes, chemical technologies, medical technologies, mechanical engineering, military equipment.

Aluminum ceramics are used for manufacturing insulators, capacitors, resistors, furnace tubes, sealing refractory parts, foundry shapes, wear pads, thermocouple protection tubes, cutting tools and polishing/grinding powders, ballistic armor, laboratory equipment, bio-ceramic parts for orthopedic and dental surgery, bearings.

About UniPreTec

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Boron Nitride, Machinable Glass Ceramic, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.