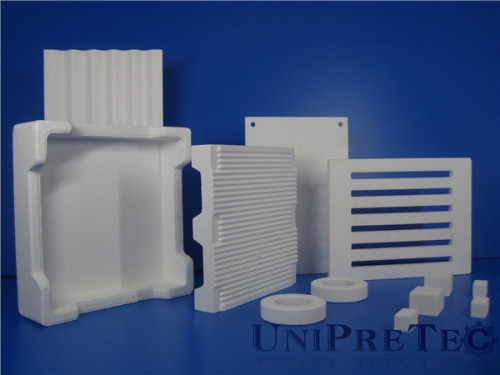

High Temperature Alumina Corundum Ceramic Sagger for Positive Electrode Material

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 30000pcs/year |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Industrial Ceramic, Advanced Ceramic, Technical Ceramic |

Product Detail

| Model No.: | UPT-ALC009 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | UNIPRETEC |

| Material: | Alumina Ceramic |

| Purity: | 85% 90% 95% |

| Color: | White |

| Shape: | Sagger |

| Density: | 2.5-3.65g/cm3 |

| Max. Working Temperature: | 1580-1770℃ |

| Porosity: | 15%-20% |

| Production Capacity: | 30000pcs/year |

| Packing: | wooden box/carton box |

| Delivery Date: | 40days |

Product Description

The Ceramic Sagger / Ceramic Setter Plate offers an all in one solution for firing of either components or powders. These saggers can be stacked directly on top of each other at Temperatures up to 1650 C. Reduced wall thickness over traditional high alumina or mullite refractory saggers can lead to increased product loading, further weight reduction, decreased cycle time.

We produce saggers for the application range up to 1750°C. We coordinate the respective sagger type and quality with our customers, depending on the chemical, thermal and geometric requirements. Our long years of experience in manufacturing saggers guarantees long service lives and high-speed heating cycles.

Typical Alumina characteristics include:

*High mechanical strength (flexural strength) and hardness;

*High wear resistance;

*High resistance to chemical attacks of strong acids and alkali even at high temperatures;

*High stiffness;

*Excellent insulating properties;

*Low coefficient of thermal expansion;

*Good fracture toughness;

*Good thermal conductivity;

*Good biocompatibility.

| Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

| Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

| Color | - | white | ivory | white | gray | white | white |

| Density | g/cm3 | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

| Flexural Strength @R.T. | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

| Compressive Strength @R.T. | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

| Thermal Conductivity @R.T. | W/(m*k) | 18-25 | 30 | 2.2 | 25 | 20 | 1.7 |

| Thermal shock resistance | Δ(℃) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

| Max. Working Temperature @R.T. | ℃ | 1500 | 1700 | 850 | 1200 | 960 | 800 |

| Volume Resistivity @R.T. | Ω*cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

| Dielectric Constant (1 MHz @R.T. ) | - | 9.5 | 9.8 | 26 | 8.2 | 4.08 | 6.02 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

Use range / applications:

(1)For firing of heavy loads pressed mullite and mullite-alumina plates have excellent resistance to sagging. Engineered compositions make smooth and flat surfaces possible while maintaining excellent thermal shock properties.

(2)For small parts firing, Unipretec offers machinable, low mass alumina fiber based compositions that eliminate the need for costly hard tooling. This allows manufacturers to customize setter configuration without costly mold charges. Low mass setters exhibit excellent thermal shock properties and by reducing the mass of the overall furnace load. This enables rapid furnace turnaround for firing parts that can withstand rapid cooling rates.

About UniPreTec

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Boron Nitride, Machinable Glass Ceramic, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.