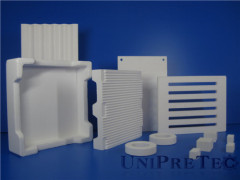

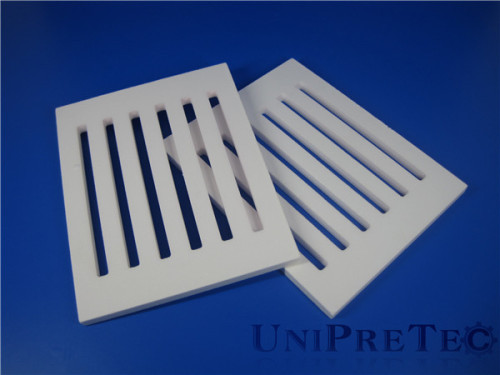

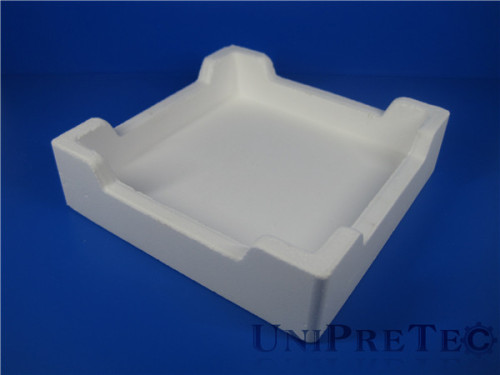

High Temperature Alumina Ceramic Components Saggers Setter Plates for Furnace Sintering

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 25000pcs/year |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Industrial Ceramic, Advanced Ceramic, Technical Ceramic |

Product Detail

| Model No.: | UPT-ALC007 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | UNIPRETEC |

| Material: | Alumina Ceramic |

| Purity: | 85% 90% 95% |

| Color: | White |

| Shape: | Plate, Sagger |

| Density: | 2.5-3.65g/cm3 |

| Max. Working Temperature: | 1580-1770℃ |

| Porosity: | 15%-20% |

| Production Capacity: | 25000pcs/year |

| Packing: | wooden box/carton box |

| Delivery Date: | 40days |

Product Description

1.Material: Alumina Ceramic, Al2O3 Ceramic, Aluminum Oxide

2.Purity: 85% 90% 95%

3.Color: White

4.Product Feture:

*Good thermal conductivity

*Good strength and hardness

*Good resistance to wear and corrosion

*Temperature resistance up to 1500°C

In the family of advanced ceramics, Alumina is the most cost effective material and it is widely used due to its resistance to corrosion, abrasion and wear. It has a good combination of mechanical and electrical properties. Al203 is excellent as electrical insulator and it is gas tight.

Aluminum Oxide can be produced by hot pressing, dry pressing or sintering and in a wide range of purities. Combining additives, its properties can be enhanced for the most demanding high temperatures. In addition, aided by metallizing and brazing techniques, Aluminum Oxide can be joined to metals.

Advantages of Alumina Ceramics

*High temperature resistance up to 1700℃

*Some kinds of advanced ceramics have high thermal shock resistance

*Corrosion resistance

*Good wear resistance

*Good dielectric properties

| Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

| Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

| Color | - | white | ivory | white | gray | white | white |

| Density | g/cm3 | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

| Flexural Strength @R.T. | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

| Compressive Strength @R.T. | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

| Thermal Conductivity @R.T. | W/(m*k) | 18-25 | 30 | 2.2 | 25 | 20 | 1.7 |

| Thermal shock resistance | Δ(℃) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

| Max. Working Temperature @R.T. | ℃ | 1500 | 1700 | 850 | 1200 | 960 | 800 |

| Volume Resistivity @R.T. | Ω*cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

| Dielectric Constant (1 MHz @R.T. ) | - | 9.5 | 9.8 | 26 | 8.2 | 4.08 | 6.02 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

Various High Temperature Ceramic Products

1.Ceramic Thermocouple Tubes

2.Ceramic Setter Plates and Saggers

3.Ceramic Crucibles

4.Break Ring for Metal Casting

5.Components for vacuum furnace

6.Welding Nozzles

7.Ceramic Spark Plug Insulators

About UniPreTec

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Boron Nitride, Machinable Glass Ceramic, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.