R32 R38 R45 T38 T45 T51 Rock Drill Tools Drill Rod Water Well Threaded MM MF Speed Drifter Extension Drill Rod

| Min. Order: | 20 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50000 pieces/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | KKD-TB06 |

|---|---|

| Means of Transport: | Ocean, Air |

| Machine Type: | Drilling Machine |

| Type: | Others |

| Brand Name: | King Kong |

| Name: | thread rod |

| Type: | thread rod |

| Machine Type: | Drilling Tool |

| Material: | 23CrNi3Mo |

| Processing Type: | Forging |

| Use: | Ore mining,drilling,quarrying, construction |

| Certificate: | ISO9001 |

| Sizes: | R25,R32,R32L,R38,R51,T30,T40 |

| Length: | different |

| Color: | Black |

| Production Capacity: | 50000 pieces/month |

| Packing: | Standard package or as your requirement |

| Delivery Date: | Depend on the quantity |

Product Description

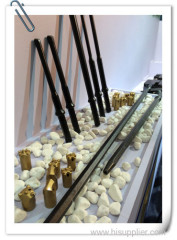

R32 R38 R45 T38 T45 T51 Rock Drill Tools Drill Rod Water Well Threaded MM MF Speed Drifter Extension Drill Rod

Choose right products

The round cross sections are more prevalent for extension drilling applications. A round rod has less material and thus is lighter to handle and less expensive than an equivalent size hexagonal rod. While hexagonal rod is particularly advantageous for drifting and tunneling drilling. The increased rigidity of hexagonal drill rods enables them to abating hole-deviation and enhances flushing for cleaning holes. Even with the larger cross section, hexagonal steel can still accommodate the same diameter bit as that of an equivalent round steel.

M/F rods provides tighter connections and is easier for handling and quicker for uncoupling than M/M rods, and are potential to drill straighter holes.

Carburization technique is mainly used in the production of big diameter rods to ensure excellent performance. Carburizing is for hardening entire rod to provide an external over entire rod surface area. Carburized steels are used primarily in underground applications and where water is used as a flushing medium. High Frequency technique is primarily used in the production of small diameter rods to reduce fragileness of drill steels. High Frequency is for hardening only the thread ends of the rod. This provides the longevity of the product as well as being more suitable for more drilling condition need. Steels produced with this technics primarily used in surface drilling applications where air is the primary flushing medium. Phosphorising is to improve anti-erosion capability of the entire external rod surface area.

Welcome to contact us if you need any tools!

Welcome to contact us if you need any tools!