D40mm tapered button bit for H19 H22 and H25 taper drill rod

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | Paypal, WU |

| Supply Ability: | 50000 pieces/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | d40mm taper drill bits |

|---|---|

| Means of Transport: | Ocean, Air, Land |

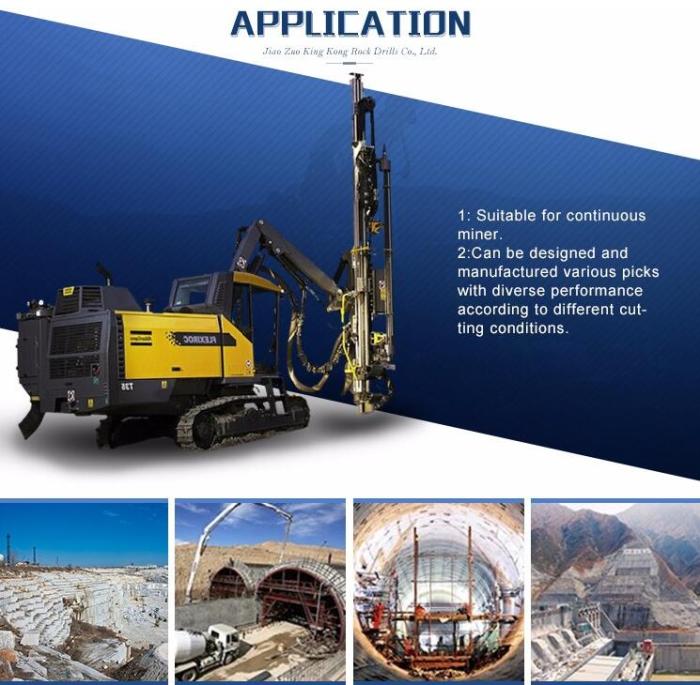

| Machine Type: | Drilling Machine |

| Type: | Drilling Tool |

| Brand Name: | kingkong |

| Name: | DTH Tools |

| Model Number: | deep hole bits |

| Diameter: | 40mm |

| air hole: | 2,3 |

| button quality: | 32,40 |

| custormization: | Available |

| Payment: | T/T |

| delivery time: | 10days |

| Production Capacity: | 50000 pieces/month |

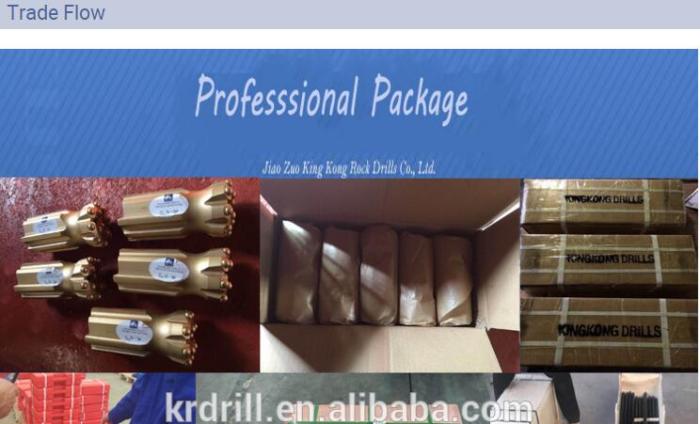

| Packing: | Standard package or as your requirement |

| Delivery Date: | Depend on the quantity |

Product Description

King Kong drill steel has high fatigue strngth,toughess and offers high was resistance giving an efficient and economic drilling operation. The unquie wear reistant carbide grade is our integreal drill steel, in combination with the generous carbide volume, provide extended service life in all applications. our unique r23 rods and bits for extension drilling provided the strongest thread in hole sizes 33-45mm. for the most aggressive applications we have fully carbuized rods with superior wear resistance and serive life.In fact working Sandvick means that you can except consist high quality and maxoperation dependability when it comes to all small hole drilllinng applications

King Kong drill steel has high fatigue strngth,toughess and offers high was resistance giving an efficient and economic drilling operation. The unquie wear reistant carbide grade is our integreal drill steel, in combination with the generous carbide volume, provide extended service life in all applications. our unique r23 rods and bits for extension drilling provided the strongest thread in hole sizes 33-45mm. for the most aggressive applications we have fully carbuized rods with superior wear resistance and serive life.In fact working Sandvick means that you can except consist high quality and maxoperation dependability when it comes to all small hole drilllinng applications

Cemented carbide is one of the most successful composite engineering materials produced.

Its unique combination of strength,hardness and toughness satisfies the most demanding applications – but working with such high stresses, inserts and buttons are more subject to wear.

King Kong's Tungsten carbide inserts are same as Sandvik YG05 sizes. and we also use the same technology as Sandvik including the steel materials and Heat treatment.

Button bits should be reground when penetrati on rat es drop or if the cemented carbide shows signs of damage

Fixed grinding routines often result in good working practices.

Bits for instance, can be examined and then reground after a specific number of holes, or at the end of the shift. Premature grinding is not necessarily uneconomical since less carbide needs to be ground off. It is better to regrind rather than reducing productivity due to damage.

Correct grinding adds considerably to drill bit service life. But equally important, it also enhances the performance of the entire drilling operation, especially hole straightness.