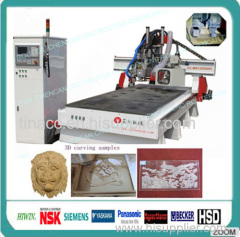

Furniture making cnc engraving machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 68/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Cnc Router Machine |

Product Detail

| Model No.: | CC-MS1335AD |

|---|---|

| Means of Transport: | Ocean, Land |

| Function: | CNC Engraving,Carving,Processing Machine |

| Work-holding:: | Stepper or Servo |

| Cooling mode: | Air-cooling |

| Dust-collect function: | Yes |

| Voltage: | 220V/380V |

| Motor: | Servo |

| Table: | Vacuum Table |

| Guide Rail: | HIWIN |

| Command: | G code (HPGL,U00,mmg,plt) |

| Operating System:: | Taiwan Syntec |

| Production Capacity: | 68/month |

| Packing: | Standard exported wooden case |

| Delivery Date: | less than 30 days |

Product Description

Furniture making cnc engraving machine

Machine category:

Woodworking CNC Router Density Board Carving Machine PVC and Acrylic Engraving machine ,Light Marble and others

Wood processing: processing of various furniture such as door, window, cabinet, craft wooden door, screen and so on.

Advertisement: engraving and cutting various labels and number plate.

Art craft: engraving characters of any languages and graphics on gifts and souvenirs.

1.Whole machine is welded with seamless steel structure; the stability is excellent, not easy to be deformed.

2.Vacuum table with 6 vacuum zones, which can adsorb different size materials and has strong suction of 23 /hour.

3. Has the function of re-carving after break point and power failure. Has the function of forecasting process time.

4.Z axis adopts Germany-made ball-screw and Taiwan made H30 linear orbit, with high precision and long lifetime. X and Y axes adopt rack and pinion transmission, faster working, higher efficiency and low cost.

5. Excellent compatibility: CAD/DAM designing software e.g.

6. Adopting Taiwan-made control system, separate keyboard control system and color LCD screen makes the machine have perfect performance.

7.Circle style automatic tool changer with 8 pieces of tools in total. Changing the tool automatically only needs 8 second. It used to engraving and drilling holes on top space.

8. Adopting high-torque Japan-made YASKAMA servo motor and driver, with steady working capability and high positioning precision.

9. Adopting Italy-made HSD air-cooling spindle make the machine have high precision, long life-time and steady working capacity. Auto-tool changer system makes the machine safer and save time.

10.Auto oil-injection system makes the maintenance more convenient.