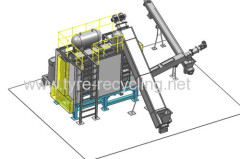

tire rubber plasticizing machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Waste Rubber Crusher Machine, Waste Whole Tire Shredder Machine, Waste Tire Cut Machine |

Product Detail

| Model No.: | RX-R10 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | LX |

| Model: | R10 |

| Capacity (kg/h): | 400-700 |

| Screen width (mm): | 600 |

| Control system: | Computer control |

| Motor Power (kw): | 165 |

| Dimension(L×W×H)(m): | 6×8×6 |

| Material Science: | Stainless steel+lron |

| Production Capacity: | 100 |

| Packing: | According customer requirement |

| Delivery Date: | 30days |

Product Description

Atmospheric pressure rubber powder plasticizing machine Desulphurization by atmospheric pressure thermal devocalizing plasticizing process and unique

Machine problem. Using electromagnetic heating, high heating efficiency and can save a lot of energy. The energy saving effect is obvious. Continuous production,

Automation control degree is high, many machine working point material saving manpower, stable product quality, the comprehensive economic benefits of higher.

1, security: working at atmospheric pressure by using heat-conducting oil furnace or electric heating, greatly reducing the accident hidden danger, ensure safety in production.

2, stable: double mixing cage feeding, stirring more uniform, even in many oil won't stick with, ensuring the stability of the production process.

3, high performance: output is greatly increased, daily output of up to 25 tons of a single, small occupation area.

4, energy saving and environmental protection, energy saving is very prominent: 1. Power consumption of 70 degrees per ton, comprehensive electricity consumption decreased by 30%, 1 people can easily operate the equipment

As. Under the same production capacity, saving manpower 2, production efficiency is improved by more than 3 times. No discharge of three wastes, continuous production, energy saving investment 50%

Energy-saving emission reduction 90% 70% reclaimed rubber is the waste rubber, plasticizer (softener and activating agent), oxygen, heat and mechanical shear

The part under the action of molecular chains and crosslinked rubber fracture, reducing the performance of rubber rubber.

II: 1, wastewater treatment, environmental protection:

(1) for cooling water circulation cooling water pond → →: recovery cycle

(2) a small amount of wastewater (wash tank), oil separation tank, sedimentation, filtration, recycling (residual wastewater

For treatment of coal combustion boiler water)

2, waste gas treatment:

Process of waste gas purification buffer tank → → → → absorption tower cooling tube absorption pump → recovery tank, no discharge of wastewater to the (absorption tower

In the above (2) flow together). Production per ton of recycled plastic waste by recycling cooling made oil 2.5 kg, as the production of raw materials and

Fuel.

Process of rubber powder plasticizing machine desulfurization:

Mix, will be crushed to 10-40 purpose of waste rubber powder adding activating agent and softening agent, by weight ratio, the rubber powder: softeners: activator

=1:8-18%:0.3-0.4% mix.

Desulfurization plasticizing will step 1 Preparation of mixture is heated to 180-320.C, heat 15-18 minutes to desulfurization plastics processing, which makes the plasticized rubber powder.

Cooling: the plasticized rubber powder plasticizing treatment after cooling to 80.C it can be used for packaging and use.