2014 NEW DESIGN SUNGLASSES WITH CARBON DECORATION

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T, WU |

| Supply Ability: | 30000 pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Optical Frame, Sunglasses, Clip-on Frames, Reading Glasses |

Product Detail

| Model No.: | 9004S |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Age: | Men |

| Frame Color: | S Black |

| Style: | Fashion Sunglasses |

| Frame Material: | Stainless |

| Lenses Color: | Smoke |

| Brand Name: | AGADA |

| FASHION SUNGLASSES: | METAL SUNGLASSES |

| POLARIZED LENS: | MEN`S SHAPE |

| Production Capacity: | 30000 pcs/month |

| Packing: | 1 PC/HARD CASE, 8 PC/BOX,80 PC/CARTON |

| Delivery Date: | 3~7 days after get payment |

Product Description

THE FEATURES:

Fashion design metal sunglasses

Polarized lens

light frame make you feel comfortable

good quality

Ready stock to offer

Special packing details

different packing hard case for your choosing

PACKING OPTIONS 1:

PACKING OPTIONS 2:

OUR ADVANTAGES:

1. We have own brand-AGADA and ABC

2. We offer ready stock for many styles with small MOQ

3. Each month we have around 5~10 new models offer

4. Small order and mixed order is accepted

5. We have a short delivery time. Especially for ready stock will be effected within 1 week.

6. OEM is welcome

F.A.Q.:

1.Could I put my own logo on the optical frames?

---Yes, of course, customer`s logo can be made by printing, laser ,engraved,embossed etc.

2. How about the quality

---Meet CE ,FDA

3.Could I buy 1 pc sample first?

---yes, sample order are supported

4. How many days you need for samples?

Could I put my own logo on samples?

---within 5 days if we have stock

---The logo should be printed only

MANUFACTURING PROCESS:

Frames&temples:

First we have wire metal frames which are made from the highest quality stainless steel which makes them of superior quality to the more brass based frames which are too pliable and far less resilient.

Barrel Polishing:

After the front parts and the temples individually cut and welded, they will be put into a barrel for between 10-20 hours. This involves rotating a batch of frames in a barrel containing special chips of wood and wax. The constant tumbling first smooth the surfaces of the frames and then buffers them to give a polished finish.

Welding

The manufacturing processes involve up to several welding operations to joint the oculars to nose-bridge.

Nose-pads:

Of vital important to the comfort of the wearer are the nose-pads. The nickel-silver frames have optical type "floating" nose-pads which assume the most comfortable position on the nose. They are also adjustable for width.

Hinges:

All the frames have optical quality hinges fixed with screws as opposed to rivets.

Screws:

All the screws are made of nickel silver.

Galvanic treatment:

The frames will go through a Electro-Plating System, which can put the color on the frames as planned. After the basic color, it will also go through a Lacquer Coating Procedue. By doing this, it will make the color stronger and last for longer time.

Lenses:

We use first quality un-breakable polarized lens

Cutting & fitting of polarized lenses:

The lenses are carefully cut by the cutting machine which is operated by specialized optician staff. By using the focometer, it will ensure all the cut lenses will comply with the Pupil Distance requirement. Then the cut lenses are fitted into the frames by the skillful and well experience workers. Special attention will be paid for the cutting lens, fitting process. The alignment will be also very important

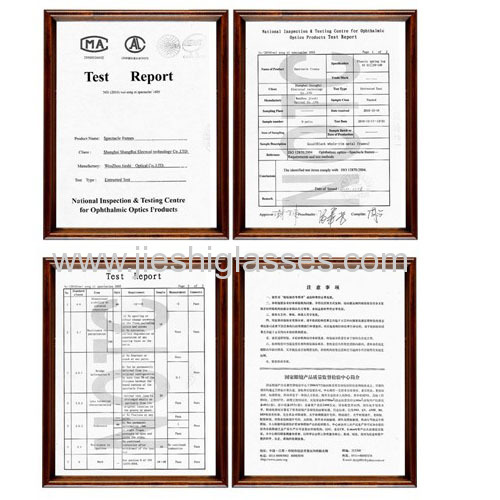

CERTIFICATION:

FACTORY SHOWS:

MANAGER:

CONTACT US: