Flat Glass Tempering Furnace

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2 |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Zhuhai, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | LINKSUN |

| Production Capacity: | 2 |

| Packing: | w |

| Delivery Date: | 30 days form purchase order |

Product Description

1. Description of the Flat Glass Tempering Furnace

1.1 Brief Introduction of Flat Glass Tempering Furnace

Flat Glass Tempering Furnace is a system of easy operation and energy saving, it includes loading table, heating section, unloading table, blowing & cooling system and control system. It is used to manufacture Continuous n tempered and heat strengthened glass for furniture, home appliance, architecture glass, auto glass and solar panel usage glass etc.

The special designed convection heating system can temper Low-E glass with high efficiency and high

productivity.

1.2 Loading Table of Flat Glass Tempering Furnace

The loading table of Flat Glass Tempering Furnace is composed of rubber-covered rollers. When the glass is put onto the rollers, the glass will be conveyed automatically to the entrance of the furnace where it will be in ready-to-enter-furnace position and the rollers stop moving. Flat Glass Tempering Furnace will send the glass into the furnace once the computer control system gives enter instruction.

Step-in button is used to control glass move forward as you wish. Side rollers and universal pop-up table make jumbo size loading easy.

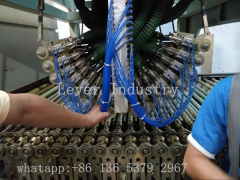

1.3 Heating Section of Flat Glass Tempering Furnace

The heating section of Flat Glass Tempering Furnace is composed of upper oven and lower oven, which is covered with thermo-insulating material. In the middle

there are high temperature resistant ceramic rollers. Heating elements are installed on the upper and lower oven. The heating element, which is high quality nickel chrome material, is of an integrated part with spiral type resistance erected on ceramic part, it's easy to replace. There are 80 heating zones in the Flat Glass Tempering Furnace

, each one has independent control loop. The upper oven can be lifted up automatically for maintenance.

When the glass is going to enter the furnace, the front door of the heating section opens, the rolls of the loading table and heating section move at the same time. When the glass is in the Glass Tempering Furnace, it moves back and forth at the same distance calculated by the controlling system automatically, so that the glass will be heated evenly.

The upper forced convection system is made of high quality stainless steel. 4 high temperature resistance convection motors are installed. Inner air circulation ensures high efficiency.

1.4 Continuous n Quenching/Cooling Section of Flat Glass Tempering Furnace

The quenching section composed of upper chiller and lower chiller, in the middle there are Kevlar roped rollers. The quenching section cover is of double-layer. The nozzles are made of aluminum profile, and the upper and lower clearance can be adjusted according to the quenching demand for different kinds of glass.

When the glass sheets come out of the heating section, high pressure air will blow to top and lower sides of the glass through air nozzles. The air pressure and flux are under control and adjusted according to different process of glass.

Pass-through section

There is a 1.2m wide pass-through section, with a bigger blower, and higher air pressure. For glass of thickness 4~6mm, it runs through this section without reciprocating and goes into the normal cooling section, where it reciprocate and to be cooled by lower air pressure. For 8mm and beyond thickness glass, this pass-through section do not working, only the normal cooling section working for quenching and cooling. This special pass-through design can save the installation power and reduce the energy concumption.

1.5 Unloading Table of Flat Glass Tempering Furnace

The unloading table is composed rubber-covered rollers and Kevlar roped rollers. When the glass is transported to the end of the table, the rollers will stop automatically, and the glass can be taken away by hand, or suction cap.

1.6 Air supply system of Flat Glass Tempering Furnace

Air supply system is composed of two air blowers, air box and air tunnels.

1.7 Control System of glass of Flat Glass Tempering Furnace

The control system includes the followings:

· The whole system of Glass Tempering Furnace is controlled by PLC, the process is fully automatic.

· Process parameters storage and re-call, such as glass thickness, size, color, glass type and maybe different sources of float glass and etc. Whenever you produce a new order for different thickness, size, color, type, source and etc., you just enter the process parameters, and the system will memorize these process data. Next time, when you have the re-order, or the same order, you can re-call the data, and the machine will automatically use the stored processing data to produce.

· Controller for roller driving system.

· Controller for the temperature control.

· Controller for quenching control.

· The abnormity alarming system would warn while trouble happens to indicate how to solve this trouble.

· The Glass Tempering Furnace has auto pre-heating function. After the shift of a day, the furnace will be in the stand-by status; only less than 25% of heating power will be consumed, while the ceramic rollers will be still running. And ahead of working time on the next morning, the system will start up to heat up to the working temperature until the operator begins the production.

· The touch screen of Glass Tempering Furnace is installed to make instruction and display; Glass Tempering Furnace can provide users with analog process status: main screen, process parameter screen, operation and maintenance screen and system parameter screen. The system of Glass Tempering Furnace has reading and writing function for process parameters, automatic control, unit equipment operation and test as well as self-diagnosis, as well as display alarming function.