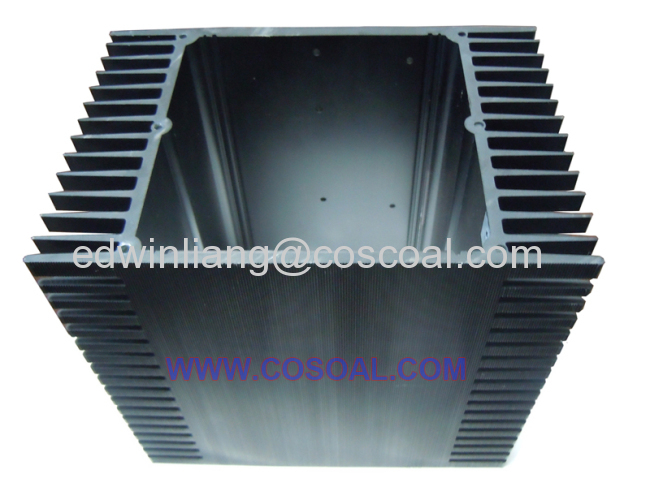

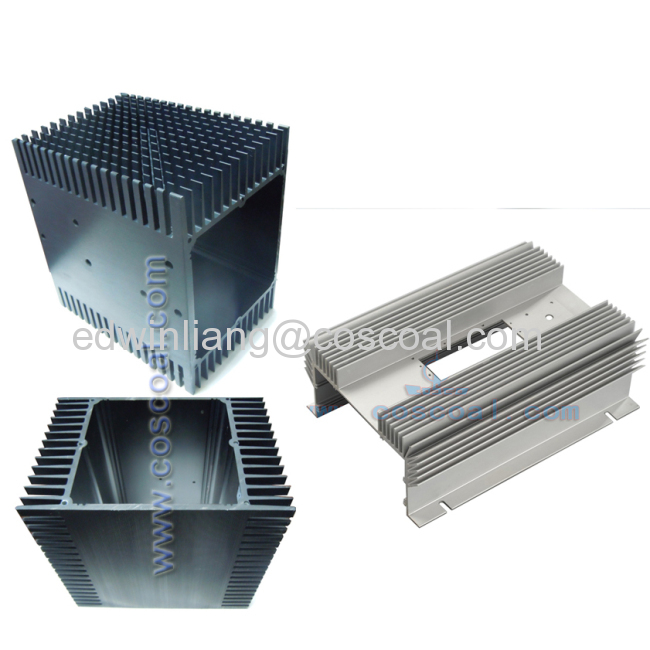

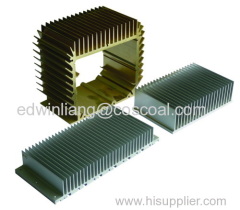

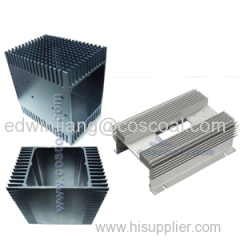

Aluminium Electronic Heat Sink

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 15000 Tons/Year |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Jiangmen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Aluminium Profile, Aluminium Extrusion Profile, Aluminium Ute Pickup Tray Body, Heatsink, Enlosure |

Product Detail

| Model No.: | ZY-10100 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Customized |

| Material: | AL 6063/6061/6060/6N01 is available |

| Temper: | T5-T6 |

| Finish: | Anodized, Electrolytic Coloring |

| Production Capacity: | 15000 Tons/Year |

| Packing: | Standard Export Packaging |

| Delivery Date: | 25 days |

Product Description

Heatsink: (Electrolytic coloring film withdraws 400 degree celcius and no discoloration and crack.)

Mob: 15992153620

E ADD: edwinliang@coscoal.com

MSN: cosco_edwin@hotmail.com

Skype: cosco_edwin

QQ: 2987772455

1) Quality material: 6063 (6061, 6060, 6005, 6082, 6N01 available)

2) Machining: Lathe/mil/CNC/Polish/punch/drill/tap available.

3) Finishing: Anodizing/powder coating/painting/silkscreening/ etc

4) Application: Forelectronis

5) OEM design/specification is welcome1) Quality material: 6063 (6061, 6060, 6005, 6082, 6N01, 5083, 8056, 3003 available)

2) Machining: Lathe/mil/CNC/Polish/punch/drill/tap available.

3) Finishing: Bright clear anodizing (powder coating/painting/silkscreening etc available)

4) Assembling and packaging

5) Application: Industrial appliance etc

6) OEM design/specification is welcome.

1. Features of the COSCO black anodized aluminium extruded heatsink.

1) Qualified aluminium alloy: 6063(6061, 6060, 6N01, 5052, 5083, 7005, 3003, etc)

2) Finish: Black anodizing(Clear anodizing/ hard anodizing/powder coating/ painting/ polishing are available)

3) Machining: Cutting, lathing, (CNC machining, punching, tapping, drilling are available)

4) OEM designs and specification are welcome

2. Lead time:

For tooling, 15-20 working days, two pieces of qualified samples free of charge for customers' approval.

For the whole batch of cargos, production lead time will depend on the customers' order quantity.

3. Payment terms: Can negotiate with customers.

Usual practise: For tooling, 100% prepaid by T/T;

For whole batch of cargos, 30% prepaid, 70% balance before delivery.

| Item | Original Products | Alternatives |

| Extrusion tolerance | GB /T5237-2000 (Chinese Standard) | EN-755-2/3/6/8, BS-1474, BS 1161 (British Standards) JIS H4100 (Japanese Standard) AS/NZS1866-1997 (Australian New Zealand Standard) |

| Machining tolerance | GB/T1804-92 | BS 8118 TS1649 |

| Standard for Anodizing | GB5237.2-2004 | BS1615: 1987 BS5599: 1993 Mil-A-8625E Type II Mil-A-8625E Type III |

| Manufacturing Process | Die designing→ Die making→ Smelting& alloying→ Extruding→ Cutting→ CNC machining→ Driling→ Tapping→ Surface treatment→ Welding→ Assembling→ Packing | |

| Packing method | 1. Standard packing: Eachprofile will be wrapped in the plastic sheet in order to protect the profiles' surfaces, kraft paper wrapped in bundles. 2. Special packing: wooden cases+iron trays. 3. Bundles or boxes with wooden bars 4. EPE+carton boxes. 5. Customized packing methods are welcomed. 6.13 tons to a 20 feet container, 20 tons to a 40 feet container |