api 5l seamless steel pipe

590.0~1000.0 USD

| Min. Order: | 10 Metric Ton |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 8000Metric Ton/Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | API 5CT BTC K55 N80 Petroleum Casing Tube, API 5L Cold Draw Seamless Carbon Steel Line Tube, ASTM A53 Gr.B SMLS Carbon Steel Tube, API 5L Gr.B Carbon Steel Seamless Tube, ASTM A53 Gr.B Carbon Steel Seamless Tube |

Product Detail

| Model No.: | api 5l |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Standard: | API 5L |

| Steel Grade: | Gr.A,Gr.B,X42-X70,,X80,X90,X100,X120 |

| OD(mm): | 10-630 |

| WT(mm): | 1.73-36.5 |

| Length(mm): | MAX14 or as agreed |

| Application: | Petroleum,chemical,power,gas,water,metallurgy,shipbuilding,construction,etc. |

| Surface Treatment: | black paint or as agreeed |

| Pipe port handling: | Threaded end,Plain end or Belled end |

| Certification: | ISO 9001-2002 ISO14001-2004 |

| Delivery condition: | As-rolled,normalized, thermomechanical,tempered,quenched |

| Production Capacity: | 8000Metric Ton/Month |

| Packing: | coating, caps and in bundles |

| Delivery Date: | about 30Days |

Product Description

Cangzhou Zhongrun Steel Pipe Co., Ltd., founded in 1994, is located in the beautiful coastal city - Changzhou.The main products:seamless steel pipe,ERW line pipe,LSAW,SSAW and Alloy steel pipe,annual sales of 100,000 tons.

In 2012 my company invested Hengchang Steel Pipe Manufacturing Co., Ltd.in Cangzhou City, the company covers an area of 100 acres, a total of eight pipe production line,annual production of about 40,000 tons.

The following is the standard data, we will do our best to follow the customers' requirements and the agreement to perform.

| Production | API 5L PSL1 PSL2 SMLS steel pipe |

| Process of manufacture | As-rolled,Heat-treated |

| Delivery condition | As-rolled,normalized, thermomechanical,tempered,quenched |

| Type of length | Fixed ruler and Double ruler |

| Inspection and Test | Tensile test,Hydrostatic test,Non-destructive inspection and as agreed |

API 5L PSL1 SMLS Chemical Composition

| Pipe/Steel Grade | C(%)≤ | Mn(%)≤ | P(%)≥ | P(%)≤ | S(%)≤ | V(%)≤ | Nb(%)≤ | Ti(%)≤ |

| L175/A25 | 0.21 | 0.6 | 0.03 | 0.03 | ||||

| L175P/A25P | 0.21 | 0.6 | 0.045 | 0.08 | 0.03 | |||

| L210/A | 0.22 | 0.9 | 0.03 | 0.03 | ||||

| L245/B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d | |

| L290/X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d | |

| L320/X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d | |

| L360/X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d | |

| L390/X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d | |

| L415/X60 | 0.28 | 1.4 | 0.03 | 0.03 | f | f | f | |

| L450/X65 | 0.28 | 1.4 | 0.03 | 0.03 | f | f | f | |

| L485/X70 | 0.28 | 1.4 | 0.03 | 0.03 | f | f | f | |

| a.Cu≤0.5%;Ni≤0.5%;Cr≤0.5% and Mo≤0.15% | ||||||||

| c.Unless otherwise agreed,Nb+V≤0.06% | ||||||||

| d.Nb+VT+Ti≤0.15% | ||||||||

| f.Unless otherwise agreed,Nb+V+Ti≤0.15% | ||||||||

| g.No deliberate addition of B is permitted and the residual B≤0.001% | ||||||||

API 5L PSL2 SMLS Chemical Composition

| Pipe/Steel grade | C(%)≤ | Si(%)≤ | Mn(%)≤ | P(%)≤ | S(%)≤ | V(%)≤ | Nb(%)≤ | Ti(%)≤ | CEiiw(%)≤ |

| L245/B | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 |

| L290/X42 | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 |

| L320/X46 | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 |

| L360/X52 | 0.24 | 0.45 | 1.5 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | 0.43 |

| L390/X56 | 0.24 | 0.45 | 1.5 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | 0.43 |

| L415/X60 | 0.24 | 0.45 | 1.7 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | 0.43 |

| L450/X65 | 0.24 | 0.45 | 1.7 | 0.025 | 0.015 | g | g | g | 0.43 |

| L485/X70 | 0.18 | 0.45 | 1.8 | 0.025 | 0.015 | g | g | g | 0.43 |

| L555/X80 | 0.18 | 0.45 | 1.9 | 0.025 | 0.015 | g | g | g | as agreed |

| L625/X90 | 0.16 | 0.45 | 1.9 | 0.02 | 0.01 | g | g | g | as agreed |

| L690/X100 | 0.16 | 0.45 | 1.9 | 0.02 | 0.01 | g | g | g | as agreed |

| The CEiiw limits apply if C>0.12% and the CEpcm limits apply if C≤0.12% | |||||||||

| g.Unless otherwise agreed,Nb+V+Ti≤0.15% | |||||||||

Tensile Properties

| Pipe/Steel grade | Yield strength(Mpa) | Tensile strength(Mpa) | ||

| minimum | maximum | minimum | maximum | |

| L245/B | 245 | 450 | 415 | 655 |

| L290/X42 | 290 | 495 | 415 | 655 |

| L320/X46 | 320 | 525 | 435 | 655 |

| L360/X52 | 360 | 530 | 460 | 760 |

| L390/X56 | 390 | 545 | 490 | 760 |

| L415/X60 | 415 | 565 | 520 | 760 |

| L450/X65 | 450 | 600 | 535 | 760 |

| L485/X70 | 485 | 635 | 570 | 760 |

| L555/X80 | 555 | 705 | 625 | 825 |

| L625/X90 | 625 | 775 | 695 | 915 |

| L690/X100 | 690 | 840 | 760 | 990 |

| L830/X120 | 830 | 1050 | 915 | 1145 |

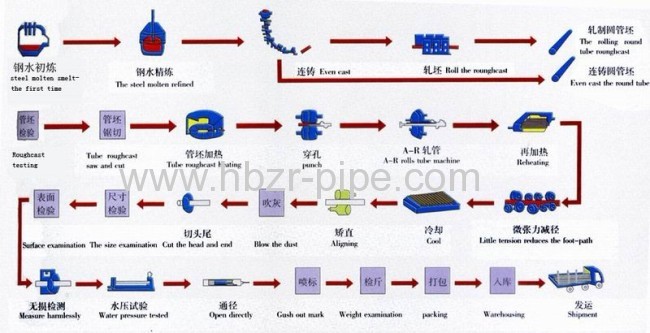

SMLS Pipes Manufacturing Process

External corrosion process

External corrosion process