High-end Automatic Drip Bag Ground Coffee Packaging Machine with Over Wrap

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300 sets/year |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | C19-III |

|---|---|

| Means of Transport: | Ocean, Land |

| Machine Materials: | SUS304 Stainless Steel |

| Machine Parts: | International Brand-name Parts |

| Machine Condition: | Fully New |

| Driven By: | Electric |

| International Approval: | ISO9001:2008 |

| Quality Approval: | Certification of Compliance |

| Experience :: | 12 Years Manufacturing |

| Orders Limit: | Small Orders Are Accepted |

| Deviation: | Extremely Small |

| Installation: | Experienced Technicians Direction |

| Production Capacity: | 300 sets/year |

| Packing: | Standard packaging. Plywood carton. |

| Delivery Date: | 30 days after down payment received |

Product Description

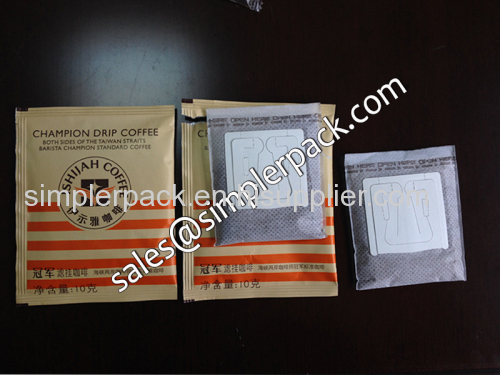

//Brief Introduction: //

1) Automatic multi-function packaging forming machine;

2) Suitable for coffee powder/ground coffee;

3) Inner drip bag is by heat sealing;

4) Food grade filter paper drip bag; with outer envelope;

5) High quality with PLC controller and PID temperature controller;

6) All-round process: filing, weighting, bag forming, sealing, cutting and counting etc.

7) Reserved connector for nitrogen flushing.

8) Quality certificated : CE, ISO9001:2008

9) Manufacturing experience : 12 years

//Application: //

It is suitable for packing 5 to 15gram ground coffee powder in drip coffee bag with outer envelop, such as Blue Mountain coffee, Brazil coffee, Italian Espresso, Kenya coffee, Columbia coffee, Hawaii Kano Coffee, Mocha Coffee etc.

//Features: //

1. Outer bag sealing is controlled by the stepper motor, ensuring accurate and stable bag length positioning.

2. Adopts PID temperature controller for more accurate temperature adjustment.

3. Adopts PLC control system and touch screen color monitor device, machine is very easy to operate.

4. The main machine parts is made of SUS304 stainless steel, so it ensures hygiene products output.

5. Some cylinders are imported, ensuring the accuracy and stability of the machines' performance.

6. It can make the inner and outer bag at the same time automatically, which would highly improve the working efficiency.

7. Adopts automatic conveyor system.

8. Leaving a reserved connector to link with nitrogen making machine, which can flush nitrogen into the bag to keep coffee fresh.

9. Options: Date code printer.

//Standard Technical Data: //

Machine type: | Drip Coffee Packaging Machine Series |

Machine model: | C19II |

Machine name: | Automatic Drip Coffee Bag Packing Machine with Outer Envelope |

Sealing method: | Inner: 3 sides sealing; Outer: 3/4 sides sealing |

Packing material: | Paper/Plastic, Plastic/Aluminum/Plastic, Paper/Aluminum/Plastic, Filter paper |

Feeding system: | Measuring cup filler |

Package range: | 5-15g |

Inner bag size: | L:50-75mm , W:50-90mm |

Outer bag size: | L:85-120mm , W:75-100mm |

Inner bag film width (180mm): | Bag size: L90mm*W75mm |

Outer bag film width(200mm): | Bag size: L120mm*W100mm |

Power supply: | Single phase, 220V, 50HZ, 3.7KW |

Packing speed: | 40-60bags/min |

Machine weight: | 400KGS |

Machine dimension: | 1200*900*1900mm(L*W*H) |

//Subordinate Category: //

1. Multi-function Packaging Machinery;

2. Packaging Forming Machines;

3. Packing Equipments;

4. Packaging Related Machinery;

5. Filling Forming Sealing Machines;

6. Bagging Machines;

7. Bag Packing Machines.

//After-Sales Service: //

1. Packaging: Standard packaging. Plywood carton.

2. Guaranteed Period: One year from lading.

3. Delivery Time: Within 25 business days after receiving down payment. The delivery time might be short if there is machine in stock.

4. Machine Installation and Training: Seller will send one technician for machine installation and training in buyer's factory on request. Buyer should offer all the travel expenses in buyer's country, as well as some traveling allowance.