Thermosetting IR tunnel dryer

Series Conveyor Dryer

DESCRIPTION:

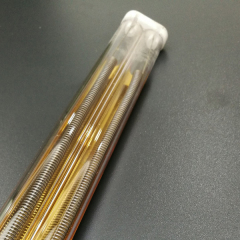

RG series infrared-red dryer is designed for the critical final step for screen printing system. RG series wider belt widths and longer belt length let you accomplish a large production output, speeding up the steps to win the market. Modular infrared heat elements instead of gas & liquid heat sources is aimed to improve curing setup and provide more higher thermal power. Three built-in turbo fans operate independently as heat flow ciculation, cool-down, exhaust. Plus high precision temperature controller system combining the multiple thermocouples ensure fast reach up to the stable operator-set temperature. In addition, RG features adjustable heating elements height knobs, teflon coated fiberglass belts, heavy-duty anodized steel rollers, asbestos filled-in insulation construction and 3-phase AC belt tracking motor. The visible temperature digital display panel and automatic shut-down system when beyond the pre-set temperature led the RG to be the most affordable and efficient dryer over the current curing territory.

STANDARD FEATURES:

1,Extremely high powered multiple infrared curing elements

2,Three turbo fans provide for heat air flows circulation, cooling, harmful exhaust respectively

3,The curing chamber is devided into three zones that can be controlled independently

4,Visiable temperature LED display delievers high precision temperature control

5,Automatic shutdown system backed with multiple thermoldoubles saves more electric energy

6,Filled-in asbestos heat resistent structure eliminates accidental contact and prevents heat migration.

7,Teflon coated fiberglass belt can be extended to 2000mm width wider.

8,Adjustablt infrared curing panel height

9,Anodized tougn steel rollers for positive belt tracking

10,Innovative drawer-shaped control panel can be hided if not used

11,Infeed/outfeed extensions are available according to customer requirements

Main technical parameters:

| Model | SCD |

| Speed | 8m/min (Adjustable) |

| Belt Width | 800-1200/mm(Optional) |

| Max. Temperature | 200℃ |

| Tunnel Length | 4000-12000/mm(Optional) |

| Size | 5560×1320×1300/mm |

| Voltage/Frequency | 3Ph 380V/50Hz |

| Heat Power | 20-60Kw |

| Note: Special sizes and specifications can be customized. |

Note: For any production problems encountered, please contact us and we will give you a best solution.