GMFG Flexo Printer Slotter Die cutter & Folder Gluer Stitcher Count Ejector Strapping Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 15 set/year |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Paper Plate, Cardboard, Honeycomb Core, Paper Angle, Feed Roller |

Product Detail

| Model No.: | GMFG 0918/GMFG 0920/GMFG 1224/GMFG 1628 |

|---|---|

| Means of Transport: | Ocean |

| Processing: | Packaging Line |

| Automatic Grade: | Automatic |

| Type: | Special |

| Usage: | Inner |

| Packaging: | Paper |

| Brand Name: | Gaint |

| Production Capacity: | 15 set/year |

| Delivery Date: | 140 days |

Product Description

GMFG Flexo Printer Slotter Die-cutter with Folder gluer

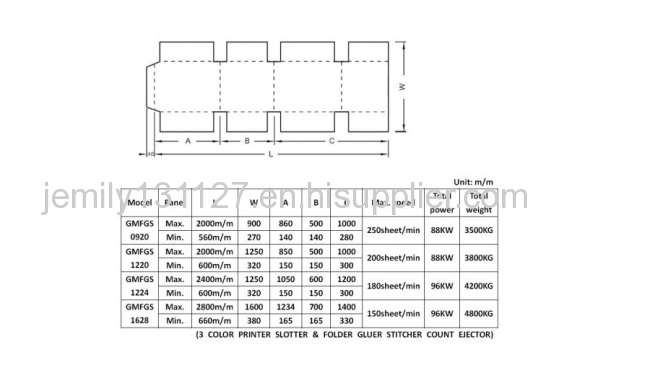

Specification of GMFG Flexo Printer Slotter Die-cutter with Folder gluer:

Brief introduction

GMFG Flexo printer slotter die cutter with in-line folder gluer counter ejector is an ideal equipment for making corrugated carton.

We also call it box maker. Usually it is used for producing small size corrugated boxes, like bear boxes, milk boxes, instant noodle box, drink box, etc...

The flexo printing line can do printing, slotting, die cutting, folding, gluing, counting, ejecting in one time.

As a big box producer, it is necessary to have such a flexo folder gluer line.

Feeding Unit

Lead edge feeding system guarantees the perfect feeding register

Automatic return to +zero position

Side guide position: Automatic , Touch Screen display

Front stop position: Motorized Operating by jog switch

Back stop position: Motorized Operating by jog switch

Feed roll nip control: Motorized, by jog switch

Pneumatic unit locking system, motorized section close/open

Continuous or skip feed with feeder counter

Dust remover to ensure high quality printing

Printing Unit

Top printing system

Automatic return to zero position

Motorized control of register. Touch screen display

Motorized impress roll nip control, by jog switch

Motorized pull roll nip control, by jog switch

Automatic to go down and up of Anilox

Printing cylinder when feeder starts and stops

Pneumatic locking system, motorized section close/open

The whole vacuum transfer system for feeding is optional.

Slotting Unit

Automatic return to zero position

Panel size: Automatic, Touch screen display

Slot depth: Automatic , Touch screen display

Box height: Automatic, Touch screen display

Creaser nip control: Motorized by jog switch

Slotter nip control: Pneumatic system

Pneumatic locking system, motorized section close/open

Dual slot system

Die cutting Unit

Automatic return to zero position

Die cylinder register: Motorized, Touch screen display

Die cylinder transfer: Motorized, Touch screen display

Die cylinder transverse moving: Range of 70mm

Anvil roll nip control: Motorized by jog switch

Pneumatic locking system, motorized section close/open system

Speed compensation system

Folder Gluer

Bottom folding system

Suction belt transportation system

Automatic glue head

Box squaring system

Computer control of box size

Stitcher

Servo control system

Max, stitching distance: 100mm

Min, stitching distance: 30mm

Max, stitching speed: 110 sheet/min

Counter Ejector

Up stacking type counter ejector

Touch screen display

Suction belt conveyor

Automatic accurate calculator and automatic ejecting