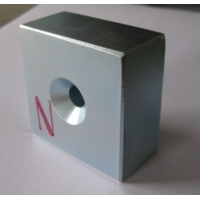

Square sharp Motor Magnet

| Min. Order: | 100 pcs |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 1200 tons yearly |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Strong Permanent SmCo Magnets, Sintered SmCo5 Samarium Cobalt Magnets, Rare Earth Permanent Magnet, N45 Arc Sintered Neodymium Motor Magnet, Industrial Sm2co17 Permanent Magnet |

Product Detail

| Model No.: | NingBoLG095 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Motor Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | LG |

| Shape: | Trapezoid |

| Composition: | Neodymium Magnet |

| Grade: | N45M |

| HS Code: | 8505909090 |

| Packing: | Plywood |

| Application: | Motors |

| Composite: | rare earth magnet |

| Material: | Ndfeb magnet |

| Certificate: | ISO9001 |

| Delivery details: | 10-15days |

| Production Capacity: | 1200 tons yearly |

| Packing: | according to customers requirement |

| Delivery Date: | according to quantity |

Product Description

Strong Neodymium Pot Magnets with inner thread holes! Made from the strong Neodymium Iron Boron magnets, punching mild steel housing and plastic spacer that all are assemble to be a set of pot magnets and then they are magnetized to be magnetic before shipment, these pot magnets offer substantially more holding and gripping power than ferrite pot magnets.

Product Name:Square sharp Motor Magnet

Product Description

High Grade Block Strong Rare Earth Neodymium Iron Boron (NdFeB) Permanent Magnet

High precision, High challenge, High quality Permanent Magnet

Introduction:

The Neodymium magnets are also known as Neo magnets, Neodymium Iron Boron magnets, Neodymium-Iron-Boron magnets, Neodymium Magnets, NdBFe magnets, NdFeB magnets, NIB magnets, Super Strength magnets and Rare Earth magnets (SmCo is also called a Rare Earth magnet). NdFeB is called a Rare Earth magnet because the Neodymium is a Rare Earth element, having a value of 60 on the Periodic Table.

Grade: N35-N54, 35M-52M, 33H-50H, 33SH-45SH, 30UH-42UH, 30EH-38EH, and 28AH-33AHB.

Coating: Ni, Zn, gold, copper, epoxy, chemical, parylene etc.

Shape: Arc, segment, disc, cylinder, sphere, block, ring, tile, and ect.

Magnetization orientation: Through thickness, axially, radially, multipole, diameter.

Typical special shape NdFeB magnet:

Ladder magnet

T-shaped magnet

Pyramid magnet

Cone magnet

Oval magnet

Convex magnet

Wedge magnet

Counterbore magnet

Triangulated pyramidal

Precision Magnets

Application:

High performance motor, Generator, Speaker, IT Products, Model Airplane, Magnetic Assembly and Magnetic Separator etc.

Temperature Characteristics:

Low grade Neodymium magnet may lose strength if heated above 80° C. High grade Neo magnets have been developed to function at temperatures up to 220° C with little irreversible loss.

Production Process:

1. Raw material prepare and mixing

2. Powder

3. Pressing

4. Sintering

5. Property inspection

6. Cutting & grinding

7. Surface treatment

8. Charging magnet

9. Inspection & Selection

10. Packing

How to get quick quotation from Ningbo LG magnet Manufacturing?

In order to quote you exactly and quickly, please offer us necessary information as below:

1. Magnet Application.

2. Magnet Grade, Br, Hcj, Working temperature, etc.

3. Magnet's property, dimensions, tolerance, surface treatment, and so on.

4. Your standard inspection method for the magnet.

5. Special requirements about the package and transportation.

6. The exact mass production quantity.

Why choose Ningbo LG 's magnet?

1. We have years experience in manufacturing NdFeB mangets.

2. We are focusing on high precision, high challenge and high quality magnets.

3. We have technological superiority, guarantee quality and competitive price.

4. We can offer fast response and fast delivery.

5.Service: Provide test report and BH curves for each item magnets, and also we could do the PCT test ,salt spray test report, aging test report and so on according to our customers'

ROFESSIONAL AND EFFICIENT MACHINING ABLITY

Ningbo LG has two machining subsidiary factories. They have inside diameter slicers, wire-cutting machines, flat grinding machines and centerless grinders, etc. The two factories have the ability to machine not only normal blocks, disks and segments, but also especially high precision small blocks and hyper-normal products, through using laser drilling and grinding to machine the SmCo products of thin-wall, deep hole, which has high precision as well as tiny hole.

EXCELLENT GEOGRAPHICAL LOCATION

Ningbo LG is located in Ningbo, an important trading port, which is close to Shanghai and well-known as China's magnetic material production base for long time. This advantage guarantees us to provide customers with kinds of difficult-machining products. With the convenient transportation, LG could ensure you a short delivery time, even your urgent products needs.

Ningbo LG supplies customers home and abroad with kinds of shapes and grades of SmCo magnets with superior quality, competitive price, short lead time and considerate service. We sincerely welcome your visit, contact and negotiation. Ningbo LG Manufacturing Co., Ltd. will be your best partner for business.

INTRODUCTION TO TECHNICAL CONSULTANT

Dr. Hartmut Nagel, who has been technical consultant since the establishment of Ningbo LG. He engaged in the SmCo research work in a global professional material and technology group—ThyssenKrupp—in Germany. Now he establishes a company, which provides NdFeB and SmCo manufacturers with equipments like hydrogen-decrepitating furnaces, pressing machines, etc, as well as technical solutions and innovative services.

| Grade | Br | Hcb | Hcj | (BH)max | (Tw) | ||||

| mT | (kGs) | kA/m | (kOe) | kA/m | (kOe) | kJ/m3 | (MGOe) | ||

| N35 | 1170-1220 | (11.7-12.2) | ≥868 | ( ≥10.9) | ≥955 | ( ≥12) | 263-287 | (33-36) | 80 ºC |

| N38 | 1220-1250 | (12.2-12.5) | ≥899 | ( ≥11.3) | ≥955 | ( ≥12) | 287-310 | (36-39) | |

| N40 | 1250-1280 | (12.5-12.8) | ≥907 | ( ≥11.4) | ≥955 | ( ≥12) | 302-326 | (38-41) | |

| N42 | 1280-1320 | (12.8-13.2) | ≥915 | ( ≥11.5) | ≥955 | ( ≥12) | 318-342 | (40-43) | |

| N45 | 1320-1380 | (13.2-13.8) | ≥923 | ( ≥11.6) | ≥955 | ( ≥12) | 342-366 | (43-46) | |

| N48 | 1380-1420 | (13.8-14.2) | ≥923 | ( ≥11.6) | ≥876 | ( ≥12) | 366-390 | (46-49) | |

| N50 | 1400-1450 | (14.0-14.5) | ≥796 | ( ≥10.0) | ≥876 | ( ≥11) | 382-406 | (48-51) | |

| N52 | 1430-1480 | (14.3-14.8) | ≥796 | ( ≥10.0) | ≥876 | ( ≥11) | 398-422 | (50-53) | |

| 30M | 1080-1130 | (10.8-11.3) | ≥796 | ( ≥10.0) | ≥1114 | ( ≥14) | 223-247 | (28-31) | 100 ºC |

| 33M | 1130-1170 | (11.3-11.7) | ≥836 | ( ≥10.5) | ≥1114 | ( ≥14) | 247-263 | (31-33) | |

| 35M | 1170-1220 | (11.7-12.2) | ≥868 | ( ≥10.9) | ≥1114 | ( ≥14) | 263-287 | (33-36) | |

| 38M | 1220-1250 | (12.2-12.5) | ≥899 | ( ≥11.3) | ≥1114 | ( ≥14) | 287-310 | (36-39) | |

| 40M | 1250-1280 | (12.5-12.8) | ≥923 | ( ≥11.6) | ≥1114 | ( ≥14) | 302-326 | (38-41) | |

| 42M | 1280-1320 | (12.8-13.2) | ≥955 | ( ≥12.0) | ≥1114 | ( ≥14) | 318-342 | (40-43) | |

| 45M | 1320-1380 | (13.2-13.8) | ≥995 | ( ≥12.5) | ≥1114 | ( ≥14) | 342-366 | (43-46) | |

| 48M | 1360-1430 | (13.6-14.3) | ≥1027 | ( ≥12.9) | ≥1114 | ( ≥14) | 366-390 | (46-49) | |

| 50M | 1400-1450 | (14.0-14.5) | ≥1033 | ( ≥13.0) | ≥1114 | ( ≥14) | 382-406 | (48-51) | |

| 30H | 1080-1130 | (10.8-11.3) | ≥796 | ( ≥10.0) | ≥1353 | ( ≥17) | 223-247 | (28-31) | 120 ºC |

| 33H | 1130-1170 | (11.3-11.7) | ≥836 | ( ≥10.5) | ≥1353 | ( ≥17) | 247-271 | (31-34) | |

| 35H | 1170-1220 | (11.7-12.2) | ≥868 | ( ≥10.9) | ≥1353 | ( ≥17) | 263-287 | (33-36) | |

| 38H | 1220-1250 | (12.2-12.5) | ≥899 | ( ≥11.3) | ≥1353 | ( ≥17) | 287-310 | (36-39) | |

| 40H | 1250-1280 | (12.5-12.8) | ≥923 | ( ≥11.6) | ≥1353 | ( ≥17) | 302-326 | (38-41) | |

| 42H | 1280-1320 | (12.8-13.2) | ≥955 | ( ≥12.0) | ≥1353 | ( ≥17) | 318-342 | (40-43) | |

| 45H | 1300-1360 | (13-13.6) | ≥963 | ( ≥12.1) | ≥1353 | ( ≥17) | 326-358 | (43-46) | |

| 48H | 1370-1430 | (13.7-14.3) | ≥995 | ( ≥12.5) | ≥1353 | ( ≥17) | 366-390 | (46-49) | |

| 30SH | 1080-1130 | (10.8-11.3) | ≥804 | ( ≥10.1) | ≥1592 | ( ≥20) | 223-247 | (28-31) | 150 ºC |

| 33SH | 1130-1170 | (11.3-11.7) | ≥844 | ( ≥10.6) | ≥1592 | ( ≥20) | 247-271 | (31-34) | |

| 35SH | 1170-1220 | (11.7-12.2) | ≥876 | ( ≥11.0) | ≥1592 | ( ≥20) | 263-287 | (33-36) | |

| 38SH | 1220-1250 | (12.2-12.5) | ≥907 | ( ≥11.4) | ≥1592 | ( ≥20) | 287-310 | (36-39) | |

| 40SH | 1240-1280 | (12.5-12.8) | ≥939 | ( ≥11.8) | ≥1592 | ( ≥20) | 302-326 | (38-41) | |

| 42SH | 1280-1320 | (12.8-13.2) | ≥987 | ( ≥12.4) | ≥1592 | ( ≥20) | 318-342 | (40-43) | |

| 45SH | 1320-1380 | (13.2-13.8) | ≥1003 | ( ≥12.6) | ≥1592 | ( ≥20) | 342-366 | (43-46) | |

| 28UH | 1020-1080 | (10.2-10.8) | ≥764 | ( ≥9.6) | ≥1990 | ( ≥25) | 207-231 | (26-29) | 180 ºC |

| 30UH | 1080-1130 | (10.8-11.3) | ≥812 | ( ≥10.2) | ≥1990 | ( ≥25) | 223-247 | (28-31) | |

| 33UH | 1130-1170 | (11.3-11.7) | ≥852 | ( ≥10.7) | ≥1990 | ( ≥25) | 247-271 | (31-34) | |

| 35UH | 1180-1220 | (11.8-12.2) | ≥860 | ( ≥10.8) | ≥1990 | ( ≥25) | 263-287 | (33-36) | |

| 38UH | 1220-1250 | (12.2-12.5) | ≥876 | ( ≥11.0) | ≥1990 | ( ≥25) | 287-310 | (36-39) | |

| 40UH | 1240-1280 | (12.5-12.8) | ≥899 | ( ≥11.3) | ≥1990 | ( ≥25) | 302-326 | (38-41) | |

| 28EH | 1040-1090 | (10.4-10.9) | ≥780 | ( ≥9.8) | ≥2388 | ( ≥30) | 207-231 | (26-29) | 200 ºC |

| 30EH | 1080-1130 | (10.8-11.3) | ≥812 | ( ≥10.2) | ≥2388 | ( ≥30) | 223-247 | (28-31) | |

| 33EH | 1130-1170 | (11.3-11.7) | ≥836 | ( ≥10.5) | ≥2388 | ( ≥30) | 247-271 | (31-34) | |

| 35EH | 1170-1220 | (11.7-12.2) | ≥876 | ( ≥11.0) | ≥2388 | ( ≥30) | 263-287 | (33-36) | |

| 38EH | 1220-1250 | (12.2-12.5) | ≥899 | ( ≥11.3) | ≥2388 | ( ≥30) | 287-310 | (36-39) | |

| 28AH | 1040-1090 | (10.4-10.9) | ≥787 | ( ≥9.9) | ≥2624 | ( ≥33) | 207-231 | (26-29) | 230 ºC |

| 30AH | 1080-1130 | (10.8-11.3) | ≥819 | ( ≥10.3) | ≥2624 | ( ≥33) | 223-247 | (28-31) | |

| 33AH | 1130-1170 | (11.3-11.7) | ≥843 | ( ≥10.6) | ≥2624 | ( ≥33) | 247-271 | (31-34) | |