solar submersible deep well pumps

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000 Piece/Pieces per month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | The Centrifugal Submersible Pump, Pump Part Small Submersible Pumps, Stainless Steel Sewage Pump, QJ Submersible Water Pumpsand The Electric Pumps, Pump Part Water Pumps Electric Pumps |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Type: | Others |

| Certification: | Others |

| Brand Name: | OEM |

| Colour: | blue, green, red,etc |

| Production Capacity: | 1000 Piece/Pieces per month |

| Packing: | wooden case |

| Delivery Date: | 7 to 15days after prepayment |

Product Description

Application field, overview

Submersible pump is a new water pumping machinery, machine and by diving submersible pump components. It is widely adapted to agricultural irrigation, urban and rural living areas, industrial and mining drainage and construction rainfall and rivers, reservoirs, fountains, refrigeration cooling systems, thermal baths and other water conservancy facilities. Its main feature is motor, water pump into the water work together as one, use, easy maintenance, high efficiency, safe and reliable operation.

Use conditions

1) Power: 380v three-phase AC, 50HZ.

2) Water quality: a) the temperature of water is below 20 (high temperature resistance 80)

b) The solid content is less than 0.01%. (According to the quality)

c) PH 6.5-8.5

d) The content of hydrogen sulfide is less than 1.15mg/l

e) The concentration of chlorides is less than 400mg/l

3) The inner part of the diving electric pump must be full of clean water and diving electric pump must safely submerge to wok.

4) Mounting depth shall not exceed 20% of water pump rated head and well face must be smooth and straight.

Cause and exclusion

Symptom | Cause | Remedy |

No water or less water | 1. Motor does not start (such as low voltage wires too small for too long, the voltage drop is too big or stuck pump does not work) | 1. Exclusion circuit failure to identify and eliminate the cause of the out of working |

Overcurrent or pointer swing | 1. Current, low head beyond the scope of use, motor overload | 1. Adjust the valves, reducing flow |

Motor winding insulation resistance geothermal below0.5MΩ | 1. Aging or damaged wire insulation | 1. Open winding wrapped with tape breakage or rewind new coil. |

Motor can't be restarted and buzzing. | 1. Broken wires or switches off (single-phase operation) | 1. Repair broken, connect to fuse |

Severe vibration motor | 1. Motor rotor is unbalanced. | 1. Rotor balance |

Motor windings burned | 1.The motor is shortage of water | 1. Attention, it must be filled with water |

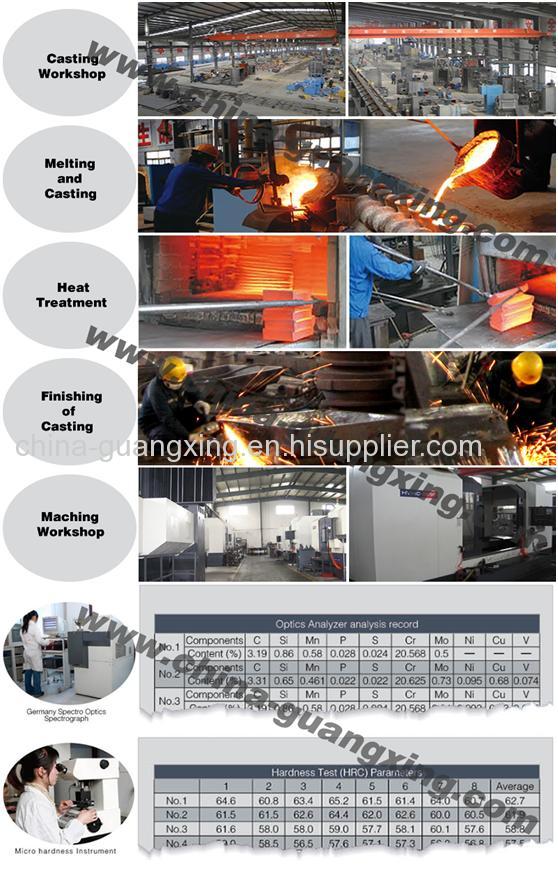

Overview of our company

.jpg)

.jpg)