QS submersible pump made in China

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T, WU |

| Supply Ability: | 1000Set/Sets |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | The Centrifugal Submersible Pump, Pump Part Small Submersible Pumps, Stainless Steel Sewage Pump, QJ Submersible Water Pumpsand The Electric Pumps, Pump Part Water Pumps Electric Pumps |

Product Detail

| Model No.: | QS |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Brand Name: | OEM |

| temperature: | <20 °C |

| Production Capacity: | 1000Set/Sets |

| Packing: | wooden case |

| Delivery Date: | witnin 15 days |

Product Description

Application field, overview

Submersible pump is a new water pumping machinery, machine and by diving submersible pump components. It is widely adapted to agricultural irrigation, urban and rural living areas, industrial and mining drainage and construction rainfall and rivers, reservoirs, fountains, refrigeration cooling systems, thermal baths and other water conservancy facilities. Its main feature is motor, water pump into the water work together as one, use, easy maintenance, high efficiency, safe and reliable operation.

Use conditions

1) Power: 380v three-phase AC, 50HZ.

2) Water quality: a) the temperature of water is below 20 (high temperature resistance 80)

b) The solid content is less than 0.01%. (According to the quality)

c) PH 6.5-8.5

d) The content of hydrogen sulfide is less than 1.15mg/l

e) The concentration of chlorides is less than 400mg/l

3) The inner part of the diving electric pump must be full of clean water and diving electric pump must safely submerge to wok.

4) Mounting depth shall not exceed 20% of water pump rated head and well face must be smooth and straight.

Installation

I. Preparing for Installation:

1. Check whether the submersible pump is in conformity with the specification stated in the conditions of use and range.

2. Heavy objects with a diameter equal to the maximum diameter submersible pump , whether measured internal diameter borehole submersible pump can be placed in and measure the depth of whether the installation requirements.

3. Check whether the Borehole cleaning, well water is turbid, not available submersible electric pump well washing sand or mud pumping water, in order to avoid premature damage of submersible pump.

4. Check whether the wellhead installation position of the clamp is appropriate, can withstand the weight of the unit

5. Follow the instructions say to check the submersible pump mechanical assembly drawings are complete, installation are in good condition, unloaded filtering, rotating shaft coupling, look to whether flexible rotation.

6. Unscrewing, add water and bleeder screw to motor cavity filled with no- corrosive clean cold water (distilled water is better, note: be sure to fill it up with), then tighten the bleeder screw.

7. Wire connection, will lead to cable and matching with electrical cable end cut to 120 mm as set, then three strands of the length of the conductor stepped stagger, stripping out of 20 mm copper core, with a knife or with gauze sand to external oxidation layer of sand, the docking of the two threads in them, with fine copper wire wound layer bind, tin welding, weld penetration, weld, sand surface debarring, then three joints, respectively, with half a lap bandage three-layer polyester insulating rubber belt, tied with nylon thread winding on both ends of the binding layer, three layers, with half fold method bandage tape again outside bandaging with high-voltage insulating tape three layers, the last three fold, and bandaged with high voltage tape five layers, each layer bandage must tighten, bed and joint is tight and firm, in order to prevent water infiltration destruction of insulation.

8. Three phase conductors with a multicenter to check whether the conduction current resistance is approximately balanced.

9. Check the circuit and transformer capacity is overloaded, followed by a good boot device, and then tilt the truth submersible pump by filling a bucket of water at the inlet section to the pump inlet, the purpose is to lubricate the pump rubber bearing, and then put upright submersible pumps secure, instant start (no more than a second), whether to agree with to identify, such as, in contrast, three-phase cable switch can be any two joints, then good filter, prepare well.

II. Installation of equipment and tools:

1. Two tons more than a pair of hanging chain. Vertical height of not less than four meters tripod (or other lifting equipment).

2. Can withstand more than a ton weight (pump can withstand the full weight) of the sling (rope) two.

3. Installation clamps (plywood) two pay.

4. Wrenches, hand hammers, screwdrivers, electrical tools and instruments, etc.

III. Pump Installation

1. Submersible pump installation is shown in Figure (Figure2)

2. Head of not less than 30 meters of submersible pump hose can be used directly with a rope or other machine and can withstand water pipes and pipe lifting the full weight of the rope in the well,

3. Head 30 meters above the pump adopts steel pipe , installed in the following order:

a) Pumps with clamp clamping the upper part (in this case a good motor and pump has been connected) with hanging chain lifted slowly into the well system until the clamp ride at the wellhead, remove the hanging chain.

b) Pay with another clamp clamping a pipe, 15 cm away from the flange with hanging chain lifted slowly down. Pipe flanges and pump flange intermediate good cushion pads, bolts, nuts and spring washer pump tube and securely tighten evenly.

c) Slightly lift the submersible pump, water pump top card hoop, fastened on the pipe with plastic tape cable, slowly under the system, make the clamp on the wellhead.

d) Use the same method to all water pipe systems into the well.

e) After the lead cable access control switches, access to three-phase power. (Submersible pump supporting switches, cable specifications: Table 2 )

IV. Attention of the installation process

1. Pump found stuck phenomenon in the process, to turn the water pipe, and the overcome sticking points, such as all kinds of measures are still doesn't work, don't force pump, submersible pumps and wells to avoid stuck or damaged.

2. When you install each tube flange should put the pads, and even forced to tighten.

3. According wells flow of sand, silt, determine the pump to the bottom of the well depth, pump must not be buried in the stream from the pump to the bottom generally not less than three meters. (Figure2)

4. Deep into the water pump should be moving into the water from the water less than 1 to 1.5 meters, otherwise damaged pump bearings. (Figure2)

5. Pump head not too low, otherwise, the need to install on the road in the mouth of the well water pipe valve to control the water pump flow at the rated flow, to prevent burn out due to high traffic and make the motor overload operation.

6. Pump operation, the water should be continuous and uniform, stable current (at rated conditions, generally no more than 10% of the rated current), no vibration and noise, if unusual, should be shut down to identify the reasons, be excluded.

7. Note that the motor ground wire set during installation, (Figure2) when the pipes for the steel pipe, clamp the lead from the wellhead; when the water pipe is plastic, leads from the pump filter screws.

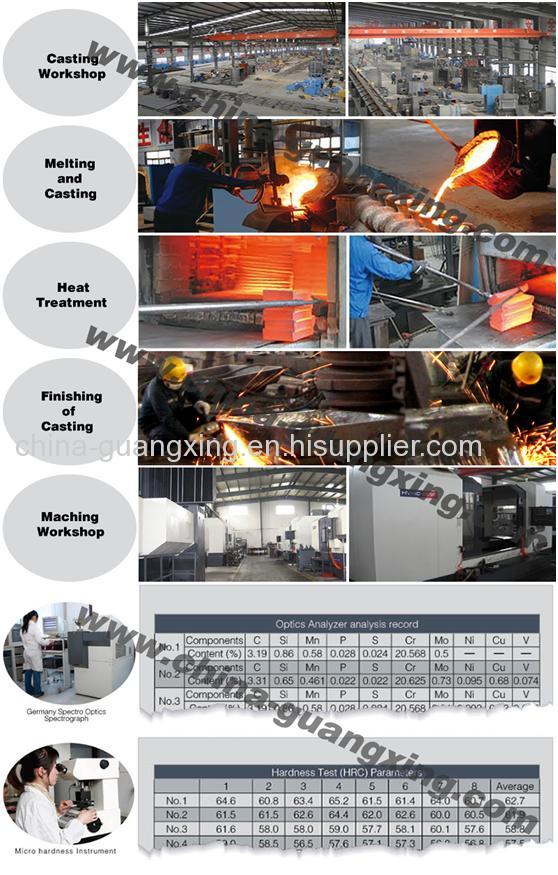

Overview of our company

.jpg)