rubber liner slurry pump

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 500 Set/Sets per Month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | The Centrifugal Submersible Pump, Pump Part Small Submersible Pumps, Stainless Steel Sewage Pump, QJ Submersible Water Pumpsand The Electric Pumps, Pump Part Water Pumps Electric Pumps |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Type: | Others |

| Certification: | CE |

| Brand Name: | GuangXing or OEM |

| Structure: | Single-stage Pump |

| Application: | Sewage, Mining |

| Usage: | Slurry pumping |

| Theory: | Centrifugal Pump |

| Material: | A05.A07.A33.A49 High chrome alloy,SS |

| Production Capacity: | 500 Set/Sets per Month |

| Packing: | wooden case |

| Delivery Date: | 1 month |

Product Description

Features

Choice of piston ring style labyrinth or other new style of water proof

Fully interchangeable with the common brand reducing inventory hold requirements

A full range of mechanical seal adaptations available upon request

Oil lubrication or packed grease

Painted to customer specifications upon request

A complete range of build specifications

Rubber lined with rubber impeller

Rubber lined with metal impeller

All metal lined using white iron chrome alloys

Urethane lined with optional urethane impeller for special applications

Pump Construction

Pump Body: Cast Iron/Grey Iron

Front Cover: High Chrome alloy/ Rubber lined

Impeller: High Chrome alloy/ Rubber lined

Mechanical Seal: Carbon/Ceramic/Stainless Steel

Motor Housing: Alloy Aluminum

Shaft: Carbon Steel/Stainless Steel/High Frequency Wedding Shaft

Insulation: Class B / Class F

Protection: IP54 / IP55

Cooling: water cooling

| SH Series Metal Slurry Pump Specifications | ||||||||

| Pump Model | S×D (inch) | Allowable Max. Power | Clear Water Performance | |||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | NPSH (m) | ||||

| m3/h | l/s | |||||||

| SH/25B | 1.5×1 | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 |

| SH/40B | 2×1.5 | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 |

| SH/50C | 3×2 | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 |

| SH/75C | 4×3 | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 |

| SH/75D | 4×3 | 60 | ||||||

| SH/100D | 6×4 | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 |

| SH/100E | 6×4 | 120 | ||||||

| SH/150E | 8×6 | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 |

| SH/150R | 8×6 | 300 | ||||||

| SH/200ST | 10×8 | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 |

| SH/250ST | 12×10 | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 |

| SH/300ST | 14×12 | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 |

| SH/350TU | 16×14 | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 |

| Remark: 1.Capacity range recommended:50%Q'≤Q≤110%Q'(Q' Appropriate to capacity at highest efficiency point). 2.NPSH: appropriate to point Q recommended at highest speed. | ||||||||

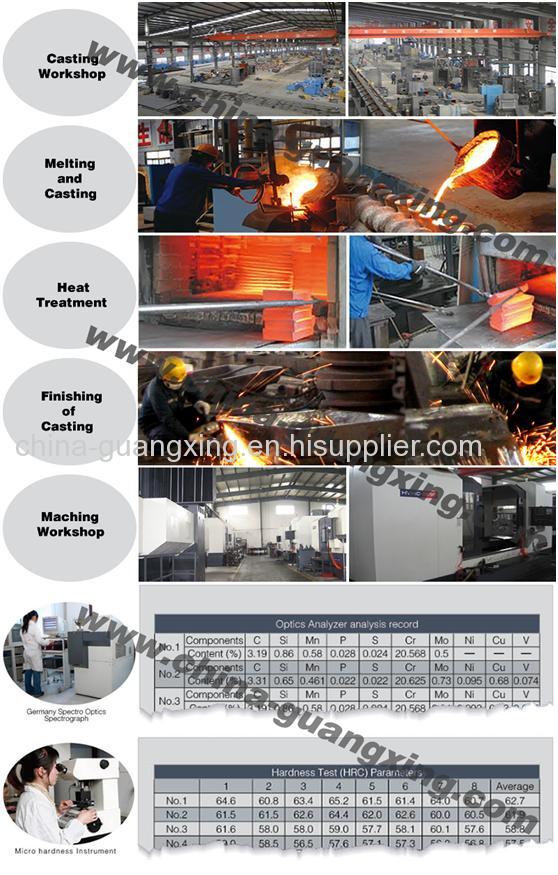

our factory

***********************************************

Please contact us at any time for more information.We will be very glad to receive any of your inquiry, and provide you our best service and products efficiently .