Insert pump parts ,Pump parts

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 50 Ton/Tons per Month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | The Centrifugal Submersible Pump, Pump Part Small Submersible Pumps, Stainless Steel Sewage Pump, QJ Submersible Water Pumpsand The Electric Pumps, Pump Part Water Pumps Electric Pumps |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Type: | Vacuum Pumps |

| Certification: | CE |

| Brand Name: | OEM |

| Place of Origin: | Shaanxi, China (Mainland) |

| Dimensions: | As per your request |

| Usage: | Water Pump |

| Application: | Industry |

| Pressure: | High Pressure |

| Material: | cast iron, stainless steel, bass |

| Production Capacity: | 50 Ton/Tons per Month |

| Packing: | 1:Barrel with wooden pallet. 2:Strong Nylon Bag |

| Delivery Date: | 1 month |

Product Description

Our Product:

1.Used for:Various casting and machining products |

2. Material: Iron, carbon steel, stainless steel, alloy steel, high manganese steel, heat resistant steel, copper alloy, aluminum alloy, Hastelloy alloy etc. |

3.Tolerance: 0.001mm after machining |

4. Tooling design and fabrication available |

5.Machining: Turning, Milling, Drilling, Grinding, Welding, Tooling, Broaching, Wire EDM etc. |

6: Surface treatment: Powder coating ,Painting ,Shot blasting, Polishing ,Electrical galvanizing, Chemical galvanizing, Chrome plating , Nickel plating, Passivation etc. |

7. Standard: AISI, ASTM, JIS, BS, DIN, ISO, EN, GB. |

Service offer:

Drawing: | We will translate your original drawing; make manufacturing procedure plan, offer professional suggestions on the design if needed. Engineering design software: Solidworks, AutoCAD.PROE DWG .DXF .IGS ,jpg formats are acceptable. |

Quality control: | We have full set of quality control system to guarantee best product quality. Depends on the products, we make different item testing plan, different manufacturing procedure and provide certified lab mechanical testing. We have the chemical analyzing chamber to analyze the component content of the material after entrance to the factory, on melting and after casting to promise the chemical component content. After getting the drawing , we first put into the software anycasting to analyze and build the mold and the feed system. We have UT, RT, MT equipment to test the product, promising the quality of the casting, both internal and surface. Also we can do the strength test for mechanical stress. Any way we can supply our costumer the qualified product, as promised. We have our Q.A. Team to promise the quality and can supply the quality certificate. and also the third part intervention for QC is also acceptable. |

Samples: | If it is only samples available, we can draw the drawings for you. |

Edges

Edges in Quality | We have years of experience and most of our clients are satisfied with our products. |

Edges in Cost | The price of is reasonable and more competitive. |

Overview of our factory

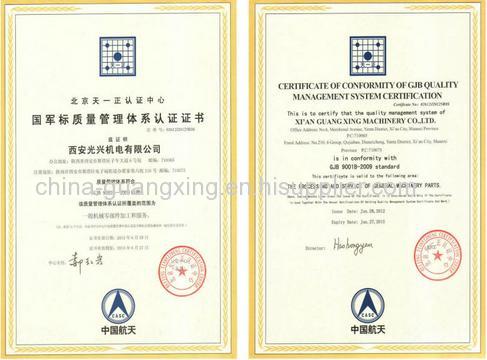

certifactions

.jpg)

.gif)