Environment friendly adhesive lined dual wall heat shrink tube

| Min. Order: | 200 Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 10,000,000 |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Heat Shrink Tube, Non-slip Heat Shrink Tube |

Product Detail

| Model No.: | SBRS-125G(2X)(3X)(4X) |

|---|---|

| Means of Transport: | Ocean, Air, Land |

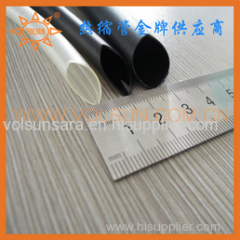

| Name: | Adhesive lined dual wall heat shrink tube |

| Type: | Heat shrink tube |

| Shrink ratio: | 2:1,3:1, 4:1 |

| Shrink temp.: | 80℃~125℃ |

| Working temp.: | -45℃~125℃ |

| Stadard: | UL 224 |

| Certificate: | RoHS |

| Colour: | Black |

| Sample: | Free |

| Delivery: | Fast express with competitive price |

| Production Capacity: | 10,000,000 |

| Packing: | Standard Export Package |

| Delivery Date: | 10Days |

Product Description

Environment Friendly Adhesive Lined Dual Wall Heat Shrink Tube

Description:

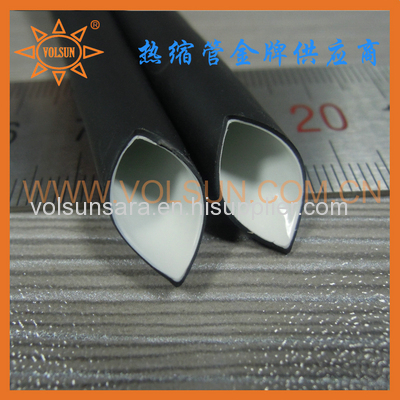

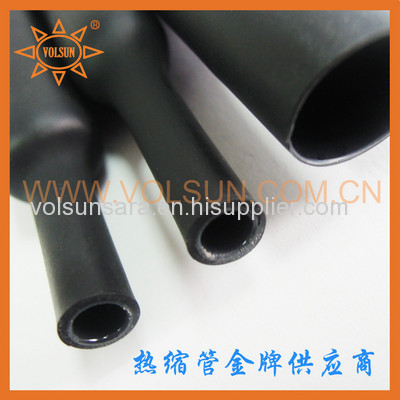

Adhesive Lined Dual Wall Heat Shrink Tube,is a cross-linked polyolefin tube that is extruded with an inner layer of adhesive. The inner layer of adhesive, with superior sealing capability, Adhesive Lined Dual Wall Heat Shrink Tube, is also a buffer against mechanical strain. Dual wall heat shrink tube is designed to provide superior sealing against water, corrosive gas and chemicals. Adhesive Lined Dual Wall Heat Shrink Tube. Typical applications include environmental sealing of in-line splices, sealing and strain relief of connectors and terminals, abrasion protection and electrical insulation of automotive wiring harness splices and valuable components, fleet & marine sealing & protection and wire bundling etc.

Adhesive Lined Dual Wall Heat Shrink Tube details:

Features:

1. Standard:UL 224

2. Shrink ratio:2:1 3:1 4:1

3. Flame retardant out layer, environmentally friendly,UV resistant

4. Shrink temperature:70°C~125℃

5. Continuous operating temperature:-45℃~125℃

6. RoHS compliant

7. Standard colors:black,other colors are available on request

Technical Data:

Property | Typical data | Test method/condition |

Tensile strength | ≥10.4MPa | ASTM D 2671 |

Elongation at break | ≥300% | ASTM D 2671 |

Tensile strength after heat aging | ≥7.3MPa | 158℃×168h |

Elongation after heat aging | ≥100% | 158℃×168h |

Longitudinal change | -8%~+8% | ASTM D 2671 |

Flammability | Self extinguishing in 30 sec. | AMS-DTL-23053/4 |

Voltage withstand(Rated voltage 600V) | 2500V,1min no breakdown | UL 224 |

Heat shock | No cracks,no dripping | UL 224,250℃×4h |

Dielectric strength | ≥15kv/mm | IEC 60243 |

Volume resistivity | ≥1014ΩNaN | IEC 60093 |

Adhesive Techical Data:

Property | Typical data | Test method/condition |

Softening point | 95±5°C | ASTM E 28 |

Water absorption | <0.5% | ASTM D 570 |

Peel strength(PE) | ≥120N/25mm | ASTM D 1000 |

Peel strength(AI) | ≥80N/25mm | ASTM D 1000 |

Dimensions:

Heat Shrink Tube Ratio(2:1)

Sizes | D I.D. As Supplied(mm) | After Full Recovery(mm) | Standard Package | ||

I.D. | Wall Thickness | Thickness of Adhesive Layer | (m/spool) | ||

Φ1.6 | ≥1.6 | ≤0.80 | 0.60±0.15 | 0.30±0.10 | 200 |

Φ2.4 | ≥2.4 | ≤1.20 | 0.70±0.15 | 0.35±0.10 | 200 |

Φ3.2 | ≥3.2 | ≤1.60 | 0.70±0.15 | 0.35±0.10 | 200 |

Φ4.8 | ≥4.8 | ≤2.40 | 0.80±0.15 | 0.40±0.10 | 100 |

Φ6.4 | ≥6.4 | ≤3.20 | 0.80±0.15 | 0.40±0.10 | 100 |

Φ7.9 | ≥7.9 | ≤3.90 | 0.90±0.15 | 0.45±0.10 | 100 |

Φ9.5 | ≥9.5 | ≤4.80 | 0.90±0.15 | 0.45±0.10 | 50 |

Φ12.7 | ≥12.7 | ≤6.40 | 0.95±0.20 | 0.45±0.10 | 25 |

Φ15.9 | ≥15.9 | ≤7.90 | 0.95±0.20 | 0.45±0.10 | 25 |

Φ19.1 | ≥19.1 | ≤9.50 | 1.00±0.20 | 0.45±0.10 | 25 |

Φ25.4 | ≥25.4 | ≤12.70 | 1.10±0.20 | 0.50±0.10 | 25 |

Φ31.8 | ≥31.8 | ≤15.0 | 1.15±0.20 | 0.50±0.10 | 1.22 |

Φ38.1 | ≥38.1 | ≤19.0 | 1.25±0.20 | 0.50±0.10 | 1.22 |

Φ44.5 | ≥44.5 | ≤22.0 | 1.35±0.20 | 0.55±0.10 | 1.22 |

Φ50.8 | ≥50.8 | ≤25.4 | 1.50±0.25 | 0.60±0.10 | 1.22 |

Heat shrink tube ration(3:1)

Size | As supplied ID(mm) | After full recovery(mm) | Standard package | |||

mm | inch | ID | Wall thickness | Thickness of adhesive | (m/spool, m/pc) | |

Φ2.4 | 3/32 | ≥2.4 | ≤0.80 | 0.85±0.15 | 0.40±0.10 | 200 |

Φ3.2 | 1/8 | ≥3.2 | ≤1.00 | 0.95±0.15 | 0.40±0.10 | 200 |

Φ4.8 | 3/16 | ≥4.8 | ≤1.60 | 1.10±0.15 | 0.40±0.10 | 100 |

Φ6.4 | 1/4 | ≥6.4 | ≤2.20 | 1.20±0.15 | 0.45±0.10 | 100 |

Φ7.9 | 5/16 | ≥7.9 | ≤2.70 | 1.35±0.15 | 0.50±0.10 | 100 |

Φ9.5 | 3/8 | ≥9.5 | ≤3.20 | 1.45±0.20 | 0.50±0.15 | 50 |

Φ12.7 | 1/2 | ≥12.7 | ≤4.20 | 1.70±0.20 | 0.50±0.15 | 25 |

Φ15.0 | 5/8 | ≥15.0 | ≤5.20 | 1.80±0.20 | 0.55±0.15 | 25 |

Φ19.1 | 3/4 | ≥19.1 | ≤6.30 | 2.00±0.20 | 0.55±0.15 | 25 |

Φ25.4 | 1 | ≥25.4 | ≤8.50 | 2.10±0.25 | 0.55±0.15 | 25 |

Φ30.0 | 1-1/4 | ≥30.0 | ≤10.20 | 2.20±0.25 | 0.60±0.15 | 1.22 |

Φ39.0 | 1-1/2 | ≥39.0 | ≤13.50 | 2.40±0.25 | 0.60±0.15 | 1.22 |

Φ50.0 | 2 | ≥50.0 | ≤17.00 | 2.70±0.25 | 0.80±0.15 | 1.22 |

Φ64.0 | 2-1/2 | ≥64.0 | ≤21.00 | 3.00±0.30 | 0.80±0.20 | 1.22 |

Φ76.0 | 3 | ≥76.0 | ≤25.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

Φ90.0 | 3-1/2 | ≥90.0 | ≤30.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

Φ100 | 4 | ≥100 | ≤34.00 | 3.00±0.30 | 1.00±0.20 | 1.22 |

Φ125 | 5 | ≥125 | ≤42.00 | 3.00±0.30 | 1.00±0.15 | 1.22 |

Heat shrink tube ratio(4:1)

Size | As supplied ID(mm) | After full recovery(mm) | Standard package | |||

mm | inch | ID | Wall thickness | Thickness of adhesive | (m/spool, m/pc) | |

Φ4.0 | 2/13 | ≥4.0 | ≤1.0 | 1.0±0.15 | 0.40±0.15 | 200 |

Φ6.0 | 1/4 | ≥6.0 | ≤1.5 | 1.1±0.15 | 0.40±0.15 | 100 |

Φ8.0 | 5/16 | ≥8.0 | ≤2.0 | 1.2±0.15 | 0.50±0.15 | 100 |

Φ12.0 | 1/2 | ≥12.0 | ≤3.0 | 1.4±0.15 | 0.50±0.15 | 25 |

Φ16.0 | 5/8 | ≥16.0 | ≤4.0 | 1.7±0.15 | 0.60±0.15 | 25 |

Φ20.0 | 15/19 | ≥20.0 | ≤5.0 | 2.0±0.25 | 0.60±0.15 | 25 |

Φ24.0 | 1 | ≥24.0 | ≤6.0 | 2.1±0.25 | 0.60±0.15 | 25 |

Φ32.0 | 1-1/4 | ≥32.0 | ≤8.0 | 2.4±0.25 | 0.70±0.15 | 1.22 |

Φ52.0 | 2 | ≥52.0 | ≤13.0 | 2.4±0.25 | 0.70±0.15 | 1.22 |

Heat shrink tube certificates:

They Trust Us:

WWW.VOLSUN.COM.CN