Cement dry mix production line

19870.0~387410.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/A, T/T |

| Supply Ability: | 30TPH |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Dry Mortar Production Line, Dry Mortar Machine, Dry Mortar Plant, Dry Mortar Mixer |

Product Detail

| Model No.: | ODCM |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | HENANORIENTAL |

| Type: | full automatic |

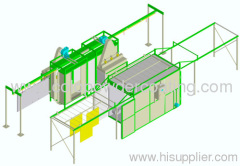

| Name: | Cement dry mix production line |

| Color: | yellow |

| Production Capacity: | 30TPH |

| Packing: | BAG |

| Delivery Date: | 29 |

Product Description

Henan oriental machinery co.,ltd. Manufacturer Cement dry mix production line Introduction

Cement dry mix production line mainly consists of the following parts: material store silo, spiral conveyor, dosing scale, bucket elevator, pre-mixing silo, small bin, mixer, end product silo, packing machine, dust collector, air compressor, air-phase balance system, second mixer, steel platform and control system.

Cement dry mix production line Raw materials of large propotion are conveyed to dosing scale by screw conveyor and small materials are conveyed by small bin. All the materials are mixed by mixer, then measured and packed automatically by packing machine, lastly conveyed to finished product stotage area by conveyor. Compared with simple-type production line, this line can not only feed large materials (cement/coal ash)automatically, but also install automatic alarm device on the storage tank.

Cement dry mix production line has the following features: feed automatically, dosing automatically, packing automatically, low cost, reasonable process,and recognized by national construction hall. The investment is about 500,000 yuan and output is 5-15 tons each hour. This line is the best choice for companies in certain scale and market, applied to manufacture exterior insulation mortar, self leveling mortar, mortar repair, waterproof mortar, HAZG, tile adhesive,joint mixture, etc.in large and medium enterprises.

Working principle full automatic Cement dry mix production line :

According to requirements of the customers, the system can be equipped with 3-6 bulk storage bins, the material in which will, after being processed by the metering and batching system, be conveyed to pending-for-mixing bin, and then fed into the high-efficiency biaxial agravic mixer for continuous mixing. The finished product in conformity with mixing accuracy requirements can be sent to the finished products bin shortly after mixed. Moreover, there is design with automatic rationing and packaging machine at the bottom of finished products bin, allowing for synchronous auto-packaging operation. Featured with easy and convenient operation, high efficiency, it can both obviously reduce labor intensity and effectively reduce dust pollution.

Features of full automatic dry mortar production line :

1. It features magnificent appearance, good quality, high productivity and accurate mortar proportioning.

2. The dry mix mortar production line uses a centralized control system, making the equipment easyto operate.

3. According to the layout type, it can be classified into tower type, self tower type and series type. Its up to the customers workshop area. The needed area is 500~5000m2.

4. We can provide one-stop service from design to installation according to our customers' specific requirement.

Application of full automatic dry mortar production line :

OMCDDM-3.7 dry mortar production line can manufacture the following various mortars:

1) Masonry mortar

2) Thin and smooth wall mortar

3) Hand-plastering screeding mortar

4) Colored coating mortar

5) Water-proofing mortar

6) Plaster powder

7) Wall plastering mortar

8) Ceramic tile adhesive mortar

9) Self-leveling mortar

10) Heat-preservation mortar

11) Tile grout

12) Gap filler

13) Repairing mortar

14) Putty powder