Pe coated paper for cups in roll

| Min. Order: | 3 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 5000tons per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | KD1-CB KD2-CB K3-CB KD2-NB |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Coated Paper Board |

| Usage: | Food Packaging |

| Brand Name: | KINDEAL |

| Size: | Based on customer request |

| Thickness: | 200um~450um |

| Weight: | 150gsm~350gsm |

| Product Material: | Paper & Paperboard |

| Paper Type: | Coated Paper,Coated paper |

| Coating Material: | PE |

| Coating Side: | Single side Double side |

| Pulp Material: | Virgin |

| Pulping Type: | Chemical-Mechanical Pulp |

| Printing Type: | Flexo printing Offset printing |

| Design requirement: | Customized logos and designs are accepted |

| Usage: | Paper cups for hot/cold drink ;Meal boxes; Paper plates ;Paper dishes; Take away food boxes; meal box paper cover; paper |

| Place of Origin: | ZHE,Zhejiang, China (Mainland), China (Mainland) |

| Production Capacity: | 5000tons per month |

| Packing: | Pe coated paper: craft paper inside, wrapping plastic outside. Cup fan: carton |

| Delivery Date: | 15 working days |

Product Description

Advantage

1.Doing pe coating from 1997

We are doing PE coating for paper since 1997.All technicians go through rigorous training of pe coating skills.

2.PE coating's smoothness and uniform is promised.

Four PE lamination machines all control by automatic man-machine interface operation, precise

3. Wastage part in roll paper decreased.

PE coating procedure is using advanced automatic paper-receiving technology to reduce the wastage at inner and outer part of paper roll.

4.Two packing procedure ensure sealing effect to protect cup paper from humidity and damage during transportation.

All PE coated paper rolls are packed by craft paper inside, then wrap several laps of plastic tight outside of craft paper.

Production Procedure

| 1. Uploading raw material paper on PE coating machine. |

| 2. Pe coating procedure PE melted in high temperature machine then evenly coating on raw material paper surface. For double pe coated paper will through an additional corona coated on printing side of paper. This procedure is must for double PE coated paper in order to print later. |

| 3. Unloading pe coated paper. After finish PE coating, discharged the finished Pe coated paper from machine |

| 4. Packing First, using craft paper pack around the pe coated paper; secondly used automatic packing machine wrapping plastics outside of paper. |

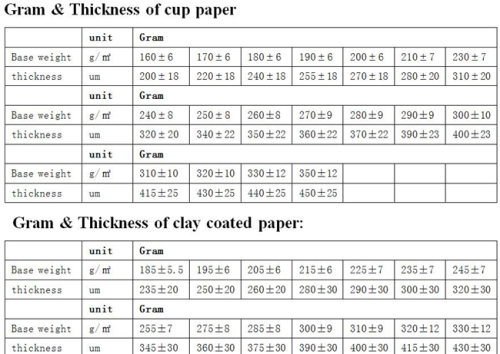

Gram & thickness of pe coated paper for cups

Product name | pe coated paper for cups in roll |

Material | 150gsm~350gsm Paper+ PE(12gsm~26gsm) |

Usage | Paper cups for hot/cold drink ;Paper plates ;Paper dishes;paper lids;Meal boxes; |

Feature | High shinny surface, good brightness, stiffness, printing effect |

Max width | Single pe coated paper for cups in roll 1600mm Double pe coated paper for cups in roll 1300mm |

Quality level | KD1-CB KD2-CB KD3-CB KD2-NB |

Packing way | Sealed package Craft packing inside, Plastic wrapping outside |

Loading | 1*20gp can load:around 15 tons pe coated paper 1*40gp can load: around 25 ton pe coated paper |

Lead time | Around 15workingdays after receive deposit |

Useage for this paper:

Single side pe coated paper:

paper cups for hot drink, such as coffee cups, tea cups, milk cups.

paper cups for dry food, such as french fries cups, meal boxes, paper plates, cake plates.

Double side pe coated paper:

paper cups for cold drink,such as coca-cola drinks, Pepsi drink cup, cold fruits paper cups, ice cream paper cups, ice cream paper lids, meal boxes, french fries cups, doggy bags, paper plates.etc s

s

We Can Supply: