pick and place machine for PWB component

3999.0~4099.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 500sets/m |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Hot Air Reflow Soldering Machine, SMT Pick And Place Machine, Reflow Oven, Stencil Printer, Desktop Automatic Chip Mounter |

Product Detail

| Model No.: | TM240A |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | Neoden |

| Applicable PCB board: | 20*20~400*360mm |

| Applicable component: | 0402~5050,SOP, QFN,IC |

| Max mounting capability: | 7000pcs/h |

| Placement head Qty: | 2 |

| Position accuracy: | 30um |

| Feeders: | 28(8mm=12,12mm=2,16mm=1,bulk IC=1) |

| Size/Weight: | 980*655*285,mm/35kg |

| programming: | Online programming and coverting from PCB diagram |

| Work Mode: | automatic |

| average working power: | 100W |

| Production Capacity: | 500sets/m |

| Packing: | Stardard export package Packing size: L112cm*W81cm*H47cm N.W.: 25KG |

| Delivery Date: | 3 working days after payment |

Product Description

SMT Pick and Place Machine TM240A

Function

Application

Applicable PCB boards & Components

Neoden TM240A automatic desktop pick and place machine is especially developed for research laboratories and small medium manufacturing enterprises, it is also suitable for serious hobbyist.

Function

Pick and place PCB components

Application

widely used in below fields

small batch production

laboratory research and development

product prototype operation

LED SMT processing and other similar processes

Applicable PCB boards & Components

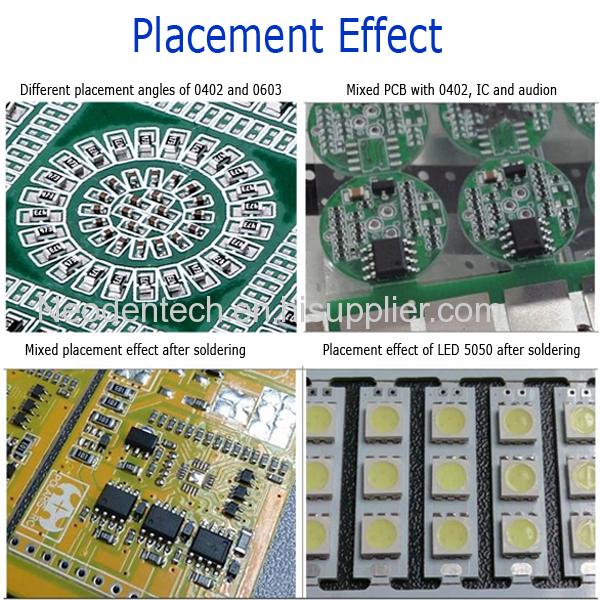

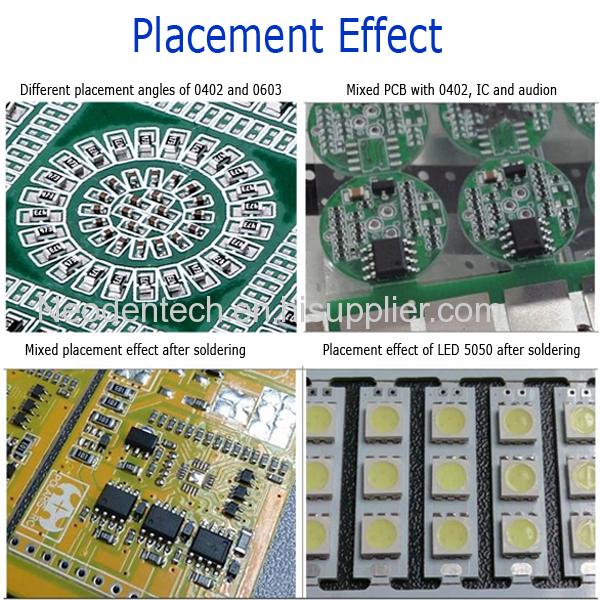

PCB Boards size:20*20~220*200mm

Components:

0402, 0603, 0805, 1206, 1812, 2010, 2512, SOT-23, LED (3528, 5050, etc

SOT89, SOP-8, SOP-14, SOP-16, SOT-223, SOT-252

IC components (IC size under 16*16mm, PIN foot less than 100, fine-pitch above 0.5mm, the height of component less than 3mm

Features

*Small and light weight body, desktop

*High mounting capability, up to 7000 pcs/h

* Dual pick and place heads, 360-degree orientation

*Vacuum detection, automatically dispose and make up if picking fail or pick misaligned

*4 types of high-precision nozzles

*Noise reduction, dual built-in mute type pumps (cost and room saving, no need to prepare additional pump)

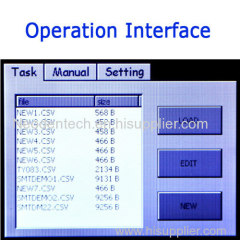

*Touchable LCD screen, friendly operation interface

*Integrated Automatic Feeders (cost saving, no need to buy extra mobile feeders)

and Automatic Nylon Spool Wheel (very convenient, tape Nylon film automatically peeled away)

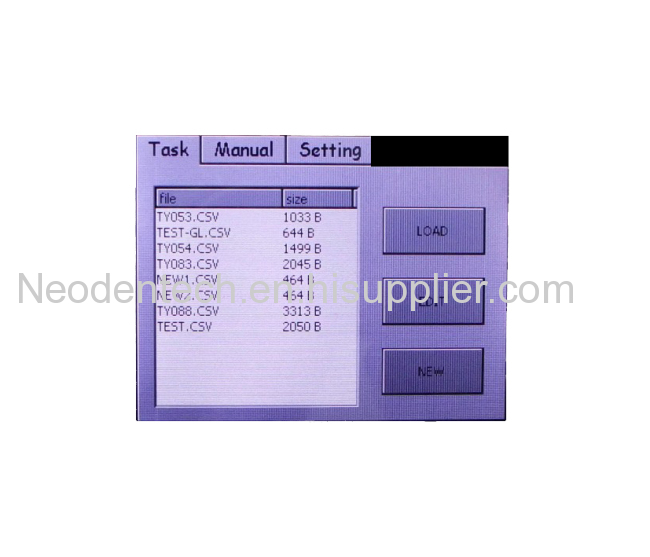

*Standard 8G SD card, mass storage of CSV working file

*Humanization design, customized feeders.

* Build-in software operating systems, converting the operating programm directly from the PCB Circuit Diagram

*Laser positioner, easy online programming, only needs 5 minutes

*Standard packagaing ensures safe transport

*Average power 100W: Environmental protection and energy saving

Technical Parameters

| Model | TM240A |

| Applicable PCB | 20mm*20mm~400mm*360mm |

| Placement head quantity | 2 |

| Max mounting capability | 7000PCS/h |

| Positioning accuracy | 30um |

| Applicable Components | 0402-5050,SOP, QFN, IC |

| Components supply configuration | Tape reel, bulk package (IC) |

| Tape width | 8mm, 12mm, 16mm |

| Feeders | 16(8mm=21, 12mm=4, 16mm=2, bulk IC=1) |

| External Dimension | L 980mm×W 655mm×H 285mm |

| Vacuum pump | -92KPA (Mute type pump) |

| Vacuum pump quantity | 3 (Built-in) |

| Power supply | 220V, 50Hz (Convertible to 110V) |

| Average working power | 100W |

| Weight | G.W: 65KG (N.W: 35KG) |

| Packing size | L 112cm×W 81cm×H 48cm |

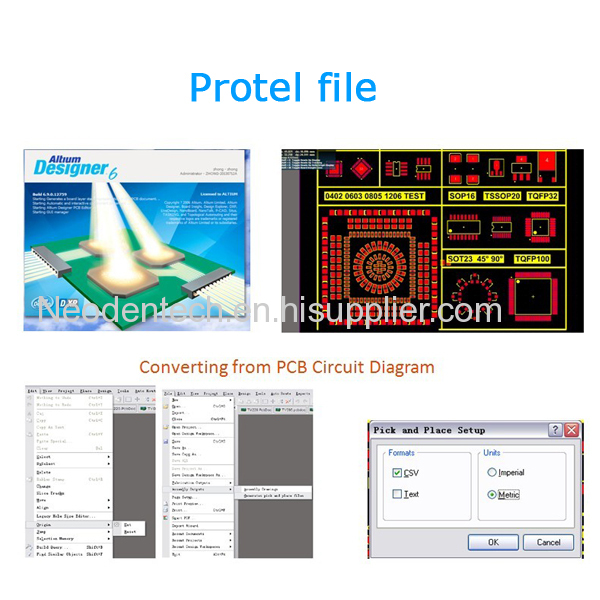

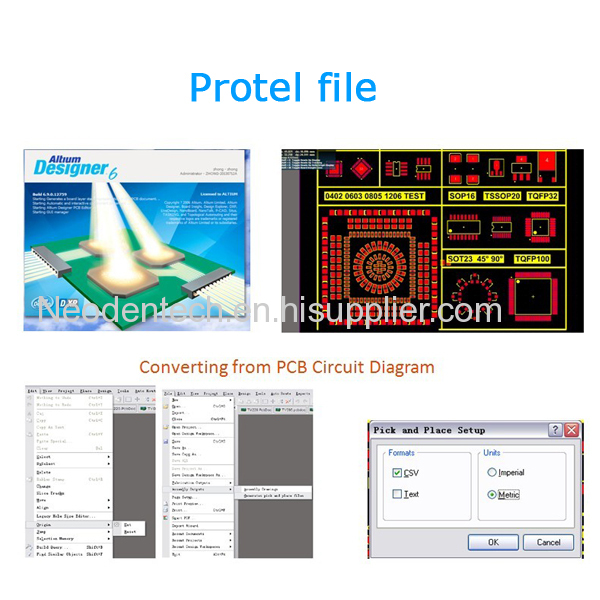

Converting from PCB Circuit Diagram or Normal file of Circuit Diagram

1. Generate coordinate CSV file form. Take software Protel Designer 6, from which we can generate Protel csv. file.

If you have Normal file, this step is not necessary.

2. Stack Management and generate PnP file

With special software Stack Management System we provide, you can open Protelor Normal file, manage stacks and their relative components, and then convert the operating program (PnP file) .

This whole process only takes 5 minutes.

Online programming

If you don't have PCBCircuit diagram or its Normal file, with the assistance of laser positioner, you can easily program for mounting components on Machine TM220A, no need any computer or other devices.

Standard Accessories

1) Pick and Place Machine TM240A: 1

2)4 types of nozzle: Totally 6 (XS-2, S-2, M-1, L-1).

3)8G SD Card: 1

4) Card reader: 1

5) Nozzle disassembly tool: 1set

6) Adjustment tool for Nylon Spool Wheel: 1

7) Nozzle cleaning tool: 1 set

8) User manual: 1

9) Video training course: 1 set

10) PCB Coordinate file transformation tool: 1