Block Ndfeb Rare Earth Magnet

0.01~100.0 USD

| Min. Order: | 2000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | as customer require one month 100000 pieces |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | High Power Irregular Neodymium Magnets, Cylinder Rare Earth Ndfeb Magnet, Block With Passivation Surface Sintered Ndfeb Magnet, Block Sintered Ndfeb Magnet |

Product Detail

| Model No.: | B05 |

|---|---|

| Means of Transport: | Ocean, Air |

| Shape: | Block |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | Dongsheng magnet |

| Grade: | N35~N52 |

| Coating: | Ni-Cu-Ni, Zn, Black Epoxy, and etc |

| Production Capacity: | as customer require one month 100000 pieces |

| Packing: | Box Carten |

| Delivery Date: | 15~30 days |

Product Description

Description

Material: NdFeB, Grade 33MGOe to 52MGOe

Dimensions: Almost any size and shape

Tolerance: +/-0.1mm

Plating/Coating: Can be NiCuNi, Zn, Epoxy, Gold and Silver etc.

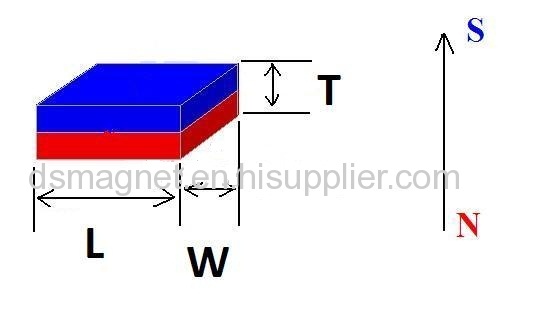

Magnetization Direction: Axially magnetized

Weight:

Surface Gauss:

Max. Working Temperature: 80ºC-200ºC

Brmax: 14,800 Gauss

BHmax: 52MGOe

Neodymium(NdFeB) magnets are made from Neodymium, iron, boron(Nd2Fe14B) and few other rare earth elements under four main production processes-raw material melting/powder making/mould pressing/sintering-to become the semi-finished products that will finally be machined and coated to be the finished parts. The main characteristics: 1)higher remanence(Br); 2)higher Coercivity(Hci) and energy product(BH); 3)lower Curie temperature(Tc). The main Applications: wind generators, DC motors, servo motors, air conditioners, medical equipment, VCM, mobile phones, speakers and magnetic holding and seperation systems etc.

NdFeB Magnet properties

| Magnet Type | Remanence(Br) | HcB | HcJ | (B-H)max | Max.Temp. | ||||

| (KGs) | (mT) | (Koe) | (KA/m) | (Koe) | (KA/m) | (MGOe) | (KJ/m3) | °C | |

| N35 | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥12 | ≥955 | 33-36 | 263-287 | 80°C |

| N38 | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥12 | ≥955 | 36-39 | 287-310 | 80°C |

| N40 | 12.5-12.8 | 1250-1280 | ≥11.4 | ≥907 | ≥12 | ≥955 | 38-41 | 302-326 | 80°C |

| N42 | 12.8-13.2 | 1280-1320 | ≥11.5 | ≥915 | ≥12 | ≥955 | 40-43 | 318-342 | 80°C |

| N45 | 13.2-13.8 | 1320-1380 | ≥11.6 | ≥923 | ≥12 | ≥955 | 43-46 | 342-366 | 80°C |

| N48 | 13.8-14.2 | 1380-1420 | ≥10.5 | ≥836 | ≥12 | ≥955 | 46-49 | 366-390 | 80°C |

| N50 | 14.0-14.5 | 1400-1450 | ≥10.0 | ≥796 | ≥11 | ≥876 | 48-51 | 382-406 | 60°C |

| N52 | 14.3-14.8 | 1430-1480 | ≥10.0 | ≥796 | ≥11 | ≥876 | 50-53 | 398-422 | 60°C |

| 33M | 11.3-11.7 | 1130-1170 | ≥10.5 | ≥836 | ≥14 | ≥1114 | 31-33 | 247-263 | 100°C |

| 35M | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥14 | ≥1114 | 33-36 | 263-287 | 100°C |

| 38M | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥14 | ≥1114 | 36-39 | 287-310 | 100°C |

| 40M | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥14 | ≥1114 | 38-41 | 302-326 | 100°C |

| 42M | 12.8-13.2 | 1280-1320 | ≥12.0 | ≥955 | ≥14 | ≥1114 | 40-43 | 318-342 | 100°C |

| 45M | 13.2-13.8 | 1320-1380 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 43-46 | 342-366 | 100°C |

| 48M | 13.6-14.3 | 1360-1430 | ≥12.9 | ≥1027 | ≥14 | ≥1114 | 46-49 | 366-390 | 100°C |

| 50M | 14.0-14.5 | 1400-1450 | ≥13.0 | ≥1033 | ≥14 | ≥1114 | 48-51 | 382-406 | 100°C |

| 35H | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 33-36 | 263-287 | 120°C |

| 38H | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 36-39 | 287-310 | 120°C |

| 40H | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 38-41 | 302-326 | 120°C |

| 42H | 12.8-13.2 | 1280-1320 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 40-43 | 318-342 | 120°C |

| 45H | 13.2-13.6 | 1320-1360 | ≥12.1 | ≥963 | ≥17 | ≥1353 | 43-46 | 342-366 | 120°C |

| 48H | 13.7-14.3 | 1370-1430 | ≥12.5 | ≥995 | ≥17 | ≥1353 | 46-49 | 366-390 | 120°C |

| 35SH | 11.7-12.2 | 1170-1220 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 33-36 | 263-287 | 150°C |

| 38SH | 12.2-12.5 | 1220-1250 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 36-39 | 287-310 | 150°C |

| 40SH | 12.5-12.8 | 1250-1280 | ≥11.8 | ≥939 | ≥20 | ≥1592 | 38-41 | 302-326 | 150°C |

| 42SH | 12.8-13.2 | 1280-1320 | ≥12.4 | ≥987 | ≥20 | ≥1592 | 40-43 | 318-342 | 150°C |

| 45SH | 13.2-13.8 | 1320-1380 | ≥12.6 | ≥1003 | ≥20 | ≥1592 | 43-46 | 342-366 | 150°C |

| 28UH | 10.2-10.8 | 1020-1080 | ≥9.6 | ≥764 | ≥25 | ≥1990 | 26-29 | 207-231 | 180°C |

| 30UH | 10.8-11.3 | 1080-1130 | ≥10.2 | ≥812 | ≥25 | ≥1990 | 28-31 | 223-247 | 180°C |

| 33UH | 11.3-11.7 | 1130-1170 | ≥10.7 | ≥852 | ≥25 | ≥1990 | 31-34 | 247-271 | 180°C |

| 35UH | 11.8-12.2 | 1180-1220 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 33-36 | 263-287 | 180°C |

| 38UH | 12.2-12.5 | 1220-1250 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 36-39 | 287-310 | 180°C |

| 40UH | 12.5-12.8 | 1250-1280 | ≥11.3 | ≥899 | ≥25 | ≥1990 | 38-41 | 302-326 | 180°C |

| 28EH | 10.4-10.9 | 1040-1090 | ≥9.8 | ≥780 | ≥30 | ≥2388 | 26-29 | 207-231 | 200°C |

| 30EH | 10.8-11.3 | 1080-1130 | ≥10.2 | ≥812 | ≥30 | ≥2388 | 28-31 | 223-247 | 200°C |

| 33EH | 11.3-11.7 | 1130-1170 | ≥10.5 | ≥836 | ≥30 | ≥2388 | 31-34 | 247-271 | 200°C |

| 35EH | 11.7-12.2 | 1170-1220 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 33-36 | 263-287 | 200°C |

| 38EH | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 36-39 | 287-310 | 200°C |

| 28AH | 10.4-10.9 | 1040-1090 | ≥9.9 | ≥787 | ≥33 | ≥2642 | 26-29 | 207-231 | 230°C |

| 30AH | 10.8-11.3 | 1080-1130 | ≥10.3 | ≥819 | ≥33 | ≥2642 | 28-31 | 223-247 | 230°C |

| 33AH | 11.3-11.7 | 1130-1170 | ≥10.6 | ≥843 | ≥33 | ≥2642 | 31-34 | 247-271 | 230°C |

Magnetization direction

Our products

PlatingCharacteristics

| Plating Type | OverallThickness | Salt SprayTest | Pressure CookerTest |

| NiCuNi (Nickel Copper Nickel) | 15-21 μm | 24 hours | 48 hours |

| NiCu + Black Nickel | 15-21 μm | 24 hours | 48 hours |

| NiCuNi + Epoxy | 20-28 μm | 48 hours | 72 hours |

| NiCuNi + Gold | 16-23 μm | 36 hours | 72 hours |

| NiCuNi + Silver | 16-23 μm | 24 hours | 48 hours |

| Zinc | 7-15 μm | 12 hours | 24 hours |

Quick Introduction on How to Send an Inquiry:

(1) Grade

(2) Size

(3) Magnetization Direction

(4) Surface Coating

(5) Quantity