Conical doube twin screw barrel

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 2000 ets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | HUACHEN |

| Material: | 38CrMoAlA,SACM645,42CrMo |

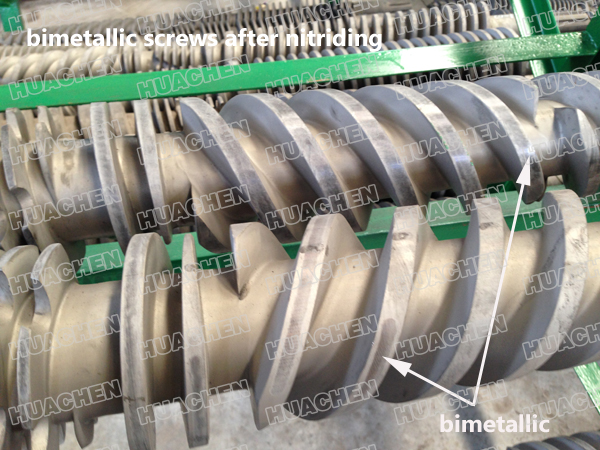

| Treatment: | Nitriding and bimetallic |

| Bimetallic layer: | add 5%-45% Tungsten Carbide |

| Apply for: | PVC PE PP... ,PVC+GF,CaCo3 |

| Machine: | Conical screw extruder machine |

| Final product: | Profile,sheet,board,pelletzing,etc. |

| Machine Brand: | Battenfeld,KMD,CINCINATI,WEBER,CHINA BRAND,etc. |

| Technology: | CNC Machines |

| Specification: | Φ15-Φ105 for China extruders, |

| Packing: | AA grade worden Case |

| Production Capacity: | 2000 ets |

| Packing: | Worden Case |

| Delivery Date: | 25-30 days |

Product Description

Conical doube twin screw barrel

Techinical Parameter

| Base Materials | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) |

| Bimetallic | 1)Fe-based alloy 2)Ni-based alloy |

| Tungsten Carbide | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of9.5% |

| Plstic material application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap orGranule),etc |

Heat Treatment | High Frequency Treatment |

Nitriding treatment(150 Hours) | Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: HV1020-1070 |

Hard Chrome Plating treatment | Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV |

| Bimetallic treatment | Bimetallic Barrel/Cylinder: Centrifugal Casting (InlayAlloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer:HRC55°-72° |

| Roughness of the surface | Ra0.4um |

| Linearity of the screw | ≤0.015mm |

| Linear axis limit | ≤0.02mm |

| Hardness after Hardening & Tempering | HB240-280 |

| Fragility of Nitration | ≤Two class |

| Roughness of the surface | Ra0.4um |

| Linearity of the screw | ≤0.015mm |

| Linear axis limit | ≤0.02mm |

| Hardness after Hardening & Tempering | HB240-280 |

| Fragility of Nitration | ≤Two class |

PRODUCTS SHOW

About conical twin screws barrel, we HUACHEN have three classes:

Nitrided screws & Nitrided barrel

Exrusion section bimetallic + total niriding screws & Extrusion section bimetallic + total nitriding barrel

Total section bimetallic + nitriding screws & Extrusion section SKD inner case + total nitrided barrel

And about bimetallic, we HUACHEN also have 4 classes:

HC-A grade: Tungsten carbide 40%

HC-B grade: Tungsten carbide 25%

HC-C grade: Tungsten carbide 15%

HC-D grade: Bimetallic without tungsten carbide

Bimetallic screws show

Bimetallic & SKD inner case barrel show

About HUACHEN

About HUACHEN

Processing

What are our SCREW and BARREL advantages:

First: Creative in designs, our designing team is very strong, since we have unique culture to motivate them, in order to meet requirement, we work closely to our customer and market!

Second: We have 20 years' experience of manufacturing varied screws, barrels and spares. We are keeping improving our production system day by day on the delivery, quality control, all the efforts have improved the customers' satisfaction!

Third: We are located along the beautiful East China Sea, Pearl,Zhoushan,Zhejiang,China's screw Town-Jintang, close to Ningbo Port and Shanghai Port!

Finally, We assure the customer benefits, we supply best quality and competitive price, also best customer service!

Exhibition show

ISO Certificate:

We want to approach the plasticizing business as a partner, not only as a supplier.

HUACHEN designs and produces all components for polymers transformation, like screws, barrels and all mechanical accessories.

Your targets, your applications, your materials are our working parameters for wastes reducing and quality improvement.

HUACHEN produces high quality products by optimizing the plasticizing process, reducing time, with the lowest percentage of wastes and at the lowest possible cost!

Our long experience in designing and producing all components of plasticizing groups, together with our knowledge of the melting process,allows us to understand your needs and to offer our best solutions at avery reasonable price!

Please contact us,if you have any questions. Mail,phone,skype all are OK.

My skype:lillianyao0421

Wechat:0086-18768075565

WhatsApp:0086-18768075565