Conical twin screw barrel for SJSZ extruder machine

500.0~30000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 2000 ets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HC-80-156 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | HUACHEN |

| Material: | 38CrMoAlA,SACM645,42CrMo |

| Treatment: | Nitriding and bimetallic |

| Bimetallic layer: | add 5%-45% Tungsten Carbide |

| Apply for: | PVC PE PP... ,PVC+GF,CaCo3 |

| Machine: | Conical screw extruder machine |

| Final product: | Profile,sheet,board,pelletzing,etc. |

| Machine Brand: | Battenfeld,KMD,CINCINATI,WEBER,CHINA BRAND,etc. |

| Technology: | CNC Machines |

| Specification: | Φ15-Φ105 for China extruders, |

| Packing: | AA grade worden Case |

| Production Capacity: | 2000 ets |

| Packing: | Worden Case |

| Delivery Date: | 25-30 days |

Product Description

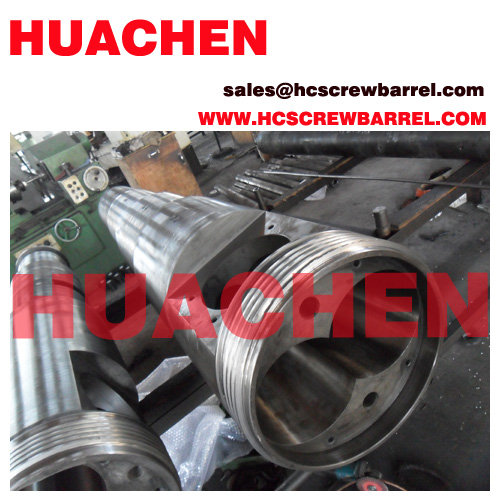

conical extruder screw barrel

We supply conical twin screw barrels apply for SJSZ, Cincinati, Battenfeld, Amut, WEBER,KRAUSS-MAFFEI

Different bimetallic alloys are available for different raw materials

Our bimetallic grade:

Bimetallic Class A:5-10% WC

Bimetallic Class B10-25% WC

Bimetallic Class C:25-45% WC

Technical Parameter

Our specification

Advantage of our conical screw barrel:

About HUACHEN Design:

Walk into HUACHEN workshop:

1.Show you how to process the screws

2.Show you how to process barrels

We supply conical twin screw barrels apply for SJSZ, Cincinati, Battenfeld, Amut, WEBER,KRAUSS-MAFFEI

,BOY and so on.

We have large numbers of drawings and we also could design for you according to your detail requirements,such as your raw plastic materials,your final products and others.

Product show:We have large numbers of drawings and we also could design for you according to your detail requirements,such as your raw plastic materials,your final products and others.

Different bimetallic alloys are available for different raw materials

Our bimetallic grade:

Bimetallic Class A:5-10% WC

Bimetallic Class B10-25% WC

Bimetallic Class C:25-45% WC

Andvantages for HUACHEN SCREW BARREL

1.Over 20 years Experience On Manufacturing Screw Barrel

1.Over 20 years Experience On Manufacturing Screw Barrel

2.Over 20 years design experience perfessional engineers service for you

3.Over 20 years good cooperation relationship with most of our customers

4.24-Hours Online Service by email or online-chat tools(Before&After sale service)

5.Prodution base on your drawing or specially design screw&barrel for you

We delievery more than 60 sets of screw and barel every day6,and about 50% is conical twin screw barrel

We delievery more than 60 sets of screw and barel every day6,and about 50% is conical twin screw barrel

Technical Parameter

Hardness after Hardening&tempering: | HB280-320 |

Nitrided Hardness: | HV900-1050 |

Nitrided Case Depth: | 0.5-0.8mm |

Nitrided Brittleness: | Less than Grade 2 |

Surface Roughness: | Ra 0.4 |

Screw Straightness: | 0.015mm |

Surface Chromium-plating's Hardness After Nitriding: | ≥900HV |

Chromium-plating Depth: | 0.025~0.10mm |

Alloy Hardness: | HRC56-65 |

Alloy Depth: | 0.8~2.0mm |

Bimetallic Thickness: | 2-5mm |

Bimetallic Hardness: | HV950-1100 |

Our specification

Advantage of our conical screw barrel:

Suitable for lens, transparent shell, cosmetics containers, transparent acrylic, nylon, PVC, PC, PPA, PPO,

PPS, PA6T, LCP, ABS, Bakelite, fire PC+ glass fiber, Nylon + glass fiber, powder, ceramic powder,

aluminum powder, iron powder and special engineering plastics.About HUACHEN Design:

For good plasticizing effect,we have different designs of extruder twin screw barrel to meet customer's demand.

We have Gradual type, Mutant type, Wave type, Barrier type,Double barrier type, Shunt type, Separation type, Exhaust type, Pintype, Mixed type, Doubel-head type, Three-head type, Multi head.Walk into HUACHEN workshop:

1.Show you how to process the screws

2.Show you how to process barrels

3.Show you the nitrogenation oven where nitrided screw and barrels

(Yes,we own the nitrogenation oven, this is in our company)

4.Testing: the picture is our workmen are testing the half-finished products.

(We test each processing step to make sure your good quality)

About HUACHEN

Our dedicated team of professionals ensures that we produce onlydefect-free products so as cater to the long list of clientele. Wepossess great process knowledge for designing different set of productsaccording to the specific requirements of our customers. Besides, ourteam members work in complete synchronization with the clients formeeting their varied industry needs and demands.

Welcom to contact us!

My skype: lillianyao0421

Choosing us is the best thing you have ever decided, and it's also our honour to be friends with u. Have a try.