Bimetallic screw barrel for HAITIAN Machine

200.0~30000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000 Sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HC-IN45 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | HUACHEN |

| Material: | 38CrMoAlA,SACM645,42CrMo |

| Treatment: | Nitriding and bimetallic |

| Bimetallic layer: | add 5%-45% Tungsten Carbide |

| Apply for: | PVC PE PP... ,PVC+GF,ABS,etc |

| Machine: | injection molding machines |

| Final product: | Profile,sheet,board,pelletzing,etc. |

| Machine Brand: | Haitian, Demag, Engle,CHINA BRANDS,etc. |

| Technology: | CNC Machines |

| Specification: | Φ15-Φ405 |

| Packing: | AA grade worden Case |

| Production Capacity: | 2000 Sets |

| Packing: | Worden Case |

| Delivery Date: | 25-30 days |

Product Description

Haitian injection screw barrel

The injection screw should be constructed of materials that provide a balance of abrasion resistance and corrosion protection. Options for construction include 38 CrMoAlA nitrided steel with abrasion resistant coating such as bimetallic or Tunsten carbide on screw flights.

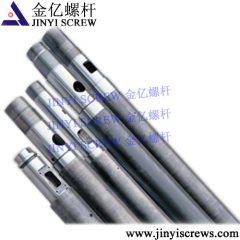

Barrel show:

Screw Show:

Products details:

Advandages of bimetallic

1. Corrosion resisting,

Some plastic materials such as Fluorine,PVC,ABS or add additive GF,etc,when temperature rise higher,will send out corrosive gas, which will damage your screw and barrel.Common nitrided screw barrel can not service long time,But bimetallic screw barrel is different,the bimetallic layer could resist the corrosion,make the screw barrel working life longer.We guarantee you the working life is one year,but our customers always use several years.

2.Wear resisting

Some times,we also need to add some materials easy to wear,such as Caco3,or recycled materials,these materials are called bad materials.Common nitrided screw barrel also could not serve you longer. Maybe half year, you need to change one set. In this situation,if you use our bimetallic screw barrel,we can guarantee one year. But our customers always use several years.

We-HUACHEN bimetalilc standard:

1. Standard grade: 38CrMoAlA + nitriding 96 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. HC-A grade: Tungsten carbide 40%

4. HC-B grade: Tungsten carbide 25%

5. HC-C grade: Tungsten carbide 15%

We-HUACHEN Bimtallilc Product Show:

Second hand extruder machine bimetallic screw barrel

Two types of bimetallic screw:

The bimetallic also could divide two types, like the above picture show:

Type 1:Sparying the bimetallic on the screw flight,this is very common in the market. If your plastic material is not very very bad,we suggest you choose this type, because of its economy.

Type 2:Coating the bimetallic on the whole screw,this is new technical these years. The advantage:Working life more longer than type 1,the disadvantage: Price is also very higher than type 1.

Injection molding screw we process as the following technical parameter:

Various kinds of screw tips,non-return valve,check rings. We also accept small order like several screw tips or others.

About Huachen

Factory Show:

Machines&processing show:

Nitrogen oven & Bimetallic Oven show:

Testing:

Certificate:

Our advantages:

- Screw and barrel for various models

- Professional engineers design for you

- Thousands of drafts can supply for you

- Professional Tech. and R&D team

- Insist on developing screws and barrels for more injection molding machine and extruder machine models

-Our screw barrel can ensure the well performance and low energy

consumption of extruder and Injection molding machine. We insist on the principle of quality first, honest to customers

And besides the injection molding machine screw and barrel, we also process extruder screw and barrel, conical twin screw and barrel, parallel twin screw and barrel,rubber machine screw and barrel,planet screw and barrel.

We can provide thousands of drawings

We can design for you according to your requirements

We can process according to your drawings.

Please contact us,if you have any questions. Mail,phone,skype all are OK.

My skype:lillianyao0421

The injection screw should be constructed of materials that provide a balance of abrasion resistance and corrosion protection. Options for construction include 38 CrMoAlA nitrided steel with abrasion resistant coating such as bimetallic or Tunsten carbide on screw flights.

Barrel show:

Screw Show:

Products details:

Advandages of bimetallic

1. Corrosion resisting,

Some plastic materials such as Fluorine,PVC,ABS or add additive GF,etc,when temperature rise higher,will send out corrosive gas, which will damage your screw and barrel.Common nitrided screw barrel can not service long time,But bimetallic screw barrel is different,the bimetallic layer could resist the corrosion,make the screw barrel working life longer.We guarantee you the working life is one year,but our customers always use several years.

2.Wear resisting

Some times,we also need to add some materials easy to wear,such as Caco3,or recycled materials,these materials are called bad materials.Common nitrided screw barrel also could not serve you longer. Maybe half year, you need to change one set. In this situation,if you use our bimetallic screw barrel,we can guarantee one year. But our customers always use several years.

We-HUACHEN bimetalilc standard:

1. Standard grade: 38CrMoAlA + nitriding 96 hours

2. Bimetallic grade: 38CrMoAlA + bimetallic alloy

3. HC-A grade: Tungsten carbide 40%

4. HC-B grade: Tungsten carbide 25%

5. HC-C grade: Tungsten carbide 15%

We-HUACHEN Bimtallilc Product Show:

Second hand extruder machine bimetallic screw barrel

Two types of bimetallic screw:

The bimetallic also could divide two types, like the above picture show:

Type 1:Sparying the bimetallic on the screw flight,this is very common in the market. If your plastic material is not very very bad,we suggest you choose this type, because of its economy.

Type 2:Coating the bimetallic on the whole screw,this is new technical these years. The advantage:Working life more longer than type 1,the disadvantage: Price is also very higher than type 1.

Injection molding screw we process as the following technical parameter:

Injection screw barrel ---Technical Parameter: | |

Nitride Case Depth | 0.6mm-0.9mm |

Nitride Hardness | 960-1160HV |

Nitride Brittleness | ≤Grade One |

Surface Roughness | Ra0.4um |

Screw Straightness | 0.015mm |

Duplex Alloy Depth | 1.5mm-3.5mm |

Duplex Alloy Hardness | HRC60-75 |

Chromium Coating Thickness | 0.025~0.10mm |

Injection screw barrel ---Technical Process: | |

Laser Coating Tungsten Carbide | Vacuum Quenching |

PTA Melt-Welding Alloy | Titanizing |

Centrifugal Mould Bimetallic Alloy | Nickel Plating |

Advanced nitrogen oozes handicraft | Chorme Plating |

About Huachen

Factory Show:

Machines&processing show:

Nitrogen oven & Bimetallic Oven show:

Testing:

Certificate:

Our advantages:

- Screw and barrel for various models

- Professional engineers design for you

- Thousands of drafts can supply for you

- Professional Tech. and R&D team

- Insist on developing screws and barrels for more injection molding machine and extruder machine models

-Our screw barrel can ensure the well performance and low energy

consumption of extruder and Injection molding machine. We insist on the principle of quality first, honest to customers

And besides the injection molding machine screw and barrel, we also process extruder screw and barrel, conical twin screw and barrel, parallel twin screw and barrel,rubber machine screw and barrel,planet screw and barrel.

We can provide thousands of drawings

We can design for you according to your requirements

We can process according to your drawings.

Please contact us,if you have any questions. Mail,phone,skype all are OK.

My skype:lillianyao0421