Planet screw and barrel

500.0~30000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 2000 ets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HC-PL |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | HUACHEN |

| Material: | High quality alloy steel |

| Treatment: | Nitriding and bimetallic |

| Bimetallic layer: | add 5%-45% Tungsten Carbide |

| Apply for: | PVC PE PP EVA and so on |

| Machine: | Conical screw extruder machine |

| Final product: | Profile,pipe sheet,board,pelletzing,etc. |

| Machine Brand: | Battenfeld,KMD,CINCINATI,WEBER,CHINA BRAND,etc. |

| Technology: | CNC Machines |

| Specification: | Φ15-Φ105 for China extruders, |

| Packing: | AA grade worden Case |

| Production Capacity: | 2000 ets |

| Packing: | Worden Case |

| Delivery Date: | 25-30 days |

Product Description

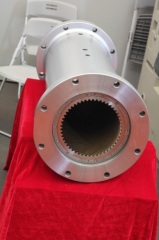

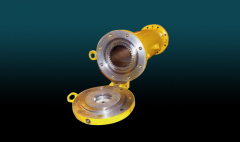

Planets screw and barrel

Key words: screw barrel,planet screw barrel,planet screw and barrel,screw and barrel

Planetary extruderextrusion system is composed ofcharging and theplanet. The charging period issimilar to normal single screwextruder'sfeeding section.

Planetary extruder is usually organized by "extrusion system" ,rotationsystem , charging system and temperature control system. The extrusionsystem hasa unique structure, the characteristics of planetary extruder isbecause of theextrusion system.

About HuachenScrew

Key words: screw barrel,planet screw barrel,planet screw and barrel,screw and barrel

Planetary extruderextrusion system is composed ofcharging and theplanet. The charging period issimilar to normal single screwextruder'sfeeding section.

Technical Parameter

HardnessafterHardening&tempering: | HB280-320 |

Nitrided Hardness: | HV900-1050 |

Nitrided Case Depth: | 0.5-0.8mm |

Nitrided Brittleness: | Less than Grade 2 |

Surface Roughness: | Ra 0.4 |

Screw Straightness: | 0.015mm |

Surface Chromium-plating'sHardnessAfterNitriding: | ≥900HV |

Chromium-plating Depth: | 0.025~0.10mm |

Alloy Hardness: | HRC56-65 |

Alloy Depth: | 0.8~2.0mm |

Bimetallic Thickness: | 2-5mm |

Bimetallic Hardness: | HV950-1100 |

Planetary extruder is usually organized by "extrusion system" ,rotationsystem , charging system and temperature control system. The extrusionsystem hasa unique structure, the characteristics of planetary extruder isbecause of theextrusion system.

The most important part of planetary extruder is planet screw barrel,itsmain function is to make raw material molten , plasticizing and mixing. Theitemis organized by a central screw, numbers of planet screws and barrelwithintramural hobbing, these three components is a key of planetary extruder.Allthe components (The center screw" planetary screw and barrel )are processedbyhigh quality alloy steel material which is high tensile ,strength andabrasionresistance. The number of planet screws is in proportion to the diameterofplanetary section, generally for 6 to 18.

Because of its high production, the planetary extruder is the best choicetoprocess PVC and other materials, such as the the EVA sheet. Singlescrewextruder's production of same type product is 800 kg per hour,twin-screwextruder production is 1200 kg per hour, and the planetary extruderproductionis 2000 kg per hour.

About HuachenScrew

Quality Assurance

Quality is our main forte and we follow varied industry policies for achieving it. Furthermore, our quality consciousness has ensured that we manufacture premium quality Screw & Barrel and machines for the clients. We conduct various quality tests on our range that start from the time of procuring raw material till the final supply of products. Apart from this, our quality controllers continuously check the entire range on different parameters so as to ensure its defect-free nature. Our quality testing laboratory is well-equipped with modern machines and technology that are necessary for bulk production.