Injection screw barrel of nitrided for ARGO,Haitian,Yizumi,ENGLE,DEMAG

200.0~30000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000 Sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HC-IN80 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | HUACHEN |

| Material: | 38CrMoAlA,SACM645,42CrMo |

| Treatment: | Nitriding and bimetallic |

| Bimetallic layer: | add 5%-45% Tungsten Carbide |

| Apply for: | PVC PE PP... ,PVC+GF,ABS,etc |

| Machine: | injection molding machines |

| Final product: | Profile,sheet,board,pelletzing,etc. |

| Machine Brand: | Haitian, Demag, Engle,CHINA BRANDS,etc. |

| Technology: | CNC Machines |

| Specification: | Φ15-Φ405 |

| Packing: | AA grade worden Case |

| Production Capacity: | 2000 Sets |

| Packing: | Worden Case |

| Delivery Date: | 25-30 days |

Product Description

HUACHEN SCREW Purpose:

To creat china famous brand,to build first-classenterprise!

Create the greatest value for ourcustomers!

Screwdiameter:Φ15mm-Φ220mm

Mould clampingforce:25-38000KN Injection capacity:30-50000g

Mould clampingforce:25-38000KN Injection capacity:30-50000g

Screwcan be designed according to different plastic material and final products

(wear-resistance corrosion- resistance, high temperature resistance, highpressure resistance)

As per customers' demand,we can supply below:

1:PMMAScrew,Bakelite Screw,PVC Screw,PA Nylon+GF Screw,PC Screw

2:All kinds of accessories, screw tip, non-return valve,check ring,nozzle,end cap

1:PMMAScrew,Bakelite Screw,PVC Screw,PA Nylon+GF Screw,PC Screw

2:All kinds of accessories, screw tip, non-return valve,check ring,nozzle,end cap

About HUACHEN

Zhejiang Huachen Screw Manufacturing Co.,Ltd is leading supplier of SCREW and BARREL in China,including designing,manufacturing and sales for these products,we can make any specification of extruder screw barrel, injection molding screw barrel, twin screw and barrel for Haitian, Demag, Engle, Nigrobossi, KMD,NPM, BOY, HUSKY, Nippon Steel, Toshiba, Nissei,Mitsubishi and etc. We also can supply all types of screw and barrel accordingto your different requirements.

HUACHEN Company

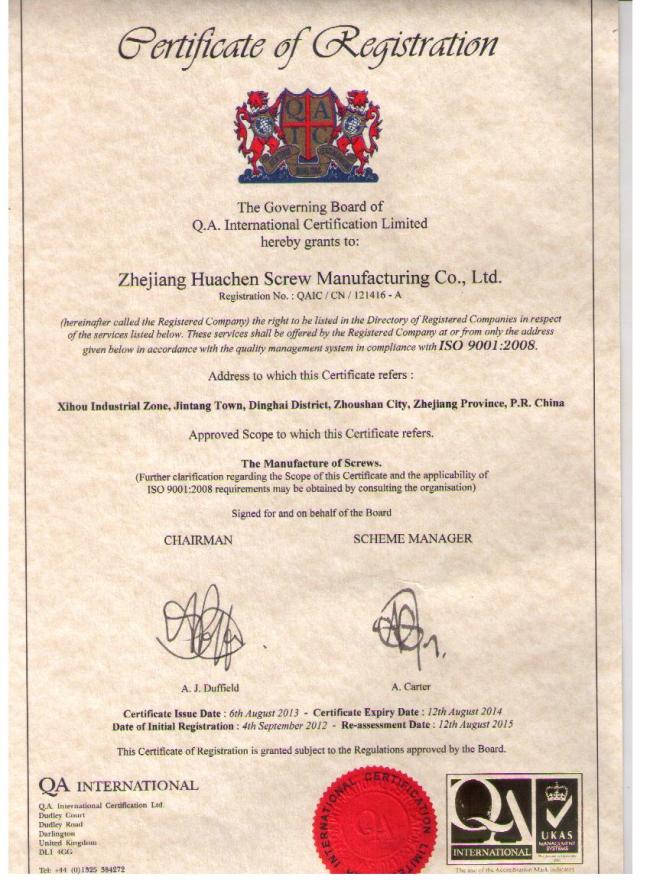

Screw and Barrel QualityCertificate:

As the screw and barrel are the important parts for plastic extruders and injection molding machine,they affect the machine performance, output and quality directly,therefore,HUACHEN established quality control system strictly as ISO9001:2008 International Quality System, our every production process is understrict inspection , Those provides solid foundation for ourquality products! What we need to do is to make sure best quality of each screw and barrel,Till now,our screw and barrel has been sold to more than 25 countriesin the world and enjoy a good reputation by our customers!

Certificate:

Basic Alloy Steel Material Weuse:

--NormalMaterial we use asfollowing:

1.38CrMoAlA(JISSACM645),

2.Cr12MOV(JISSKD-11)

3.4Cr5MoSiV1(JIS SKD-61)

4.42CrMo(AISI4140)

--The foreign material we usedasfollowing:

1. Germanysteel, GH113 ,2250,2842,1.8509 ,1.442 ,1.6582 ,1.6523 ,1.2080,1.4542,

2. USAsteel,P20,420,L6,H13,W110,D3,A2,D6,O1,S1,M35,8620,3115,K52440

3. Swedensteel,718S,718H,S136,S136H,STAVAX,ASP-23,ASP-30

4. AustraliaSteel,M202,M300,W302,K460,W300,K900,K100,W321

5. Hardnesssteel, YG6X,YG6A,YG6,YG8N,YG8,YG8C,YG11C,YG 15,YT5,YT14,YT30

6. Japan Steel, SKT 4,YXM4,YXM42,SNC 815,SK -3,SKS 3,and etc.TechnicalParameters:

sheet 1

| Base Materials | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) 3)4Cr5MoSiV1(JISSKD-61)4)42CrMo(AISI 4140) |

| Bimetallic | 1)Fe-based alloy 2)Ni-based alloy 3)Co-based alloy4)NiCo-basedalloy 5)Tungsten carbide/Wolfram carbide |

| Tungsten Carbide | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containingtungstenof9.5% |

Sheet 2

| Plstic material application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(inScraporGranule),etc |

Sheet 3

Heat Treatment | High Frequency Treatment |

Nitriding treatment(120 Hours) | Depth of Nitrided Layer: 0.5-0.8 mm Hardness of NitridedLayer:900-1020Hv(HRC56°-65°) |

Hard Chrome Plating treatment | Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV |

| Bimetallic treatment | BimetallicBarrel/Cylinder: Centrifugal Casting(InlayAlloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness ofBimetallicLayer:HRC55°-72° |

sheet4

| Roughness of the surface | Ra0.4um |

| Linearity of the screw | ≤0.015mm |

| Linear axis limit | ≤0.02mm |

| Hardness after Hardening & Tempering | HB240-280 |

| Fragility of Nitration | ≤Two class |

Besides nitrided screw barrel, we also provide bimetallic screw barrel,chromium plating screw barrel,WC coating screw barrel.titanize plating screw barrel and etc.

Sample product show:

The picture is a full set of injectionscrew barrel includeScrew Tip,Check Ring,Non-return Valve,Nozzle(Long and short),End Cap.

Thesize of this set:

Screw size: D80*2175mm Barrel size:D185*2079mm

Treatment:nitrided screw and nitrided barrel

InjectionMachine Brand:ARGO

Family Photo:

Part 1: Screw

Part 2: screw tip sets(3 brothers)Screw tip,Non-return Valve and Check ring

Part 3:Barrel

Part 4: End Cap

Part 5: Nozzle (short and long)

The longone is our gift to customer. O(∩_∩)O~

Any other questions,please feel free to contact us!