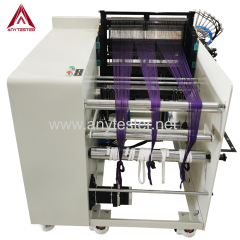

Automatic Rapier Sampling Loom

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 30 sets/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hong Kong Island, Hong Kong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | AT248 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Electronic |

| Usage: | Textile Testing Instrument |

| Brand Name: | Anytester |

| Display: | LCD |

| Type: | Digital |

| Power supply: | 220V, 50Hz |

| Certificate: | CO |

| Product: | Brand new |

| HS code: | 9024.1090.00 |

| Production Capacity: | 30 sets/month |

| Packing: | Wooden box |

| Delivery Date: | 4 ~ 6 weeks |

Product Description

1. Application:

AT248 Automatic Rapier Sample Loom is used for sample weaving of all kinds of fabrics, such as cotton, hair, jute, silk, chemical fiber, blending, etc. It consists of pneumatic shedding, rapier weft insertion, mechanical let-off, mechanical beating-up, mechanical take-up and pneumatic selection of weft yarns. It is widely used in weaving mills, scientific research units, textile institutes and foreign trade companies, etc.

2. Features:

« PLC control touch screen with 2G memory capacity to store designed patterns;

« Designable and editable patterns and USB interface to share designed patters;

« Mechanical let-off, beating-up and take-up and pneumatic shedding and selection of weft yarns;

« Pneumatic Dobby shedding mechanism to avoid the disadvantage of easy to wear for traditional peg mechanical structure;

« Rapier weft insertion, suitable for various yarns, such as, cotton, terylene/cotton, wool chemical fiber and other fabrics;

« Heald frames up to 20pcs, easy to mount and dismount;

« Automatic pneumatic selection of weft yarns up to 8 colors;

« Professional software for designing or editing patterns;

3. Technical Specification:

Model | AT248 |

Reed width | 20 inches |

Yarn linear density range | 5~500tex |

Weft density | 30~45weft/min, selectable |

No. of heald frame | 4~20 |

Color selection | 8 color, automatic pneumatic control |

Let-off | Active electronic control |

Take-up | Motor control |

Shedding | Dobby shedding, pneumatic control |

Beating-up | Motor control |

Air pressure | 0.45~0.8Mpa |

Air consumption | Max. 200L/min |

Power | A220V 50Hz, single-phase |

Machine dimension | 1200*1600*1100mm (20 inch machine) |

Machine weight | Around 600kg (20 inch machine) |

Package dimension | 2200*1500*1300mm (20 inch machine) |

Package weight | 700kg (20 inch machine) |

6. Company Overview:

Factory profile