Bronze 3-way Ball Valve

| Min. Order: | 2500 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Manual Two Piece Lead Free Brass Ball Valve, Threaded Brass Ball Valve, Brass Gate Valve Threaded, CSA Approved Brass Gas Ball Valve, 600WOG Pressure Lead Free Brass Ball Valve |

Product Detail

| Model No.: | Q144 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Manual |

| Standard or Nonstandard: | Standard |

| Structure: | Ball |

| Material: | Others |

| Media: | Water |

| Brand Name: | Huaping |

| Power:: | Manual |

| Port Size:: | Full Port |

| Material:: | Bronze |

| Pressure:: | 400WOG |

| Packing: | According to customer's requirment |

| Delivery Date: | 45day |

Product Description

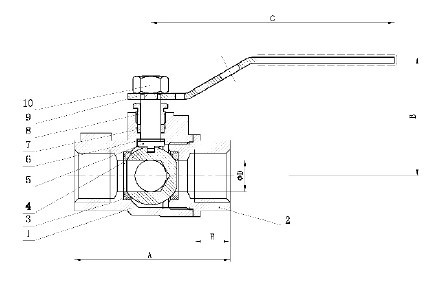

Part Name:Bronze 3-way Ball Valve

Material List:

| Item | Part | Material |

| 1 | Body | Bronze |

| 2 | End Cap | Bronze |

| 3 | Ball Seat | PTFE |

| 4 | Ball | Brass |

| 5 | Stem | Brass |

| 6 | Seat | PTFE |

| 7 | Seal | PTFE |

| 8 | Packing Nut | Brass |

| 9 | Lever Handle | Zinc Plating Steel |

| 10 | Stem Nut | Nickel Plating Steel |

Dimensions:

| Q144 | |||||

| Size | A | B | C | D | E |

| 1/2" | 2.469 | 1.882 | 3.858 | 0.504 | 0.630 |

Bronze 3-Way Ball Valve,Threaded

• Size:1/2"

Features:

Ideal for applications requiring flow deversion, this valve combines the features of two 2-Way valves

Its large ports make tank selection and fluid transfers simpler

Easy quarter-turn operation

Drilled and tapped mounting pad for panel mounting

400 psig CWP, non-shock rating

Material Control

• Sampling inspection is performed towards each batch of material,using ARL spectrum analyzer.

Machining Quality Control

• Self-check in machining process includes 1st article inspection and in-process inspetion(record the data of product every hour).

• Quality inspector performs several time?stour inspection and record the result as well.

In-coming Materials Inspection

• All components made in-house or outsourced are inspected before coming into components warehouse.

Assembly Line Quality Control

• The first batch of selected products are assembled and inspected by assembly worker and record is available.

• Tour inspector performs several times check at the assembly line and record the data.

• Worker performs visual check at the appearance of products.

Leakage Testing

• All casting parts and assembly products are under 100% leakage test.

Final Inspection before Delivery

• Inspector performs sampling check from the packaged products, and qualified products are allowed for delivery from finished products warehouse.

.jpg)

.jpg)

.jpg)