Two-piece Brass Ball Waste Valve

| Min. Order: | 1500 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Manual Two Piece Lead Free Brass Ball Valve, Threaded Brass Ball Valve, Brass Gate Valve Threaded, CSA Approved Brass Gas Ball Valve, 600WOG Pressure Lead Free Brass Ball Valve |

Product Detail

| Model No.: | 117 |

|---|---|

| Means of Transport: | Ocean |

| Standard or Nonstandard: | Standard |

| Pressure: | Medium Pressure |

| Structure: | Ball |

| Material: | Brass |

| Media: | Water |

| Brand Name: | Huaping |

| Power:: | Manual |

| Port Size:: | Full Port |

| Pressure:: | 600WOG |

| Media:: | Water,Oil,Gas |

| Certification:: | NSF/ANSI61 |

| Packing: | According to customer's requirment |

| Delivery Date: | 45day |

Product Description

Part name:Brass Ball & Waste Valve

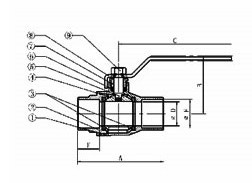

Material List:

| Item | Part | Material |

| 1 | Body | Brass |

| 2 | End Cap | Brass |

| 3 | Ball Seat | PTFE |

| 4 | Ball | Brass |

| 5 | Stem | Brass |

| 6 | Stem Packing | PTFE |

| 7 | Packing Nut | Brass |

| 8 | Lever Handle | Nickle Plating Steel |

| 9 | Stem Nut | Nickle Plating Steel |

| 10 | Drainable Nut | Brass |

| 11 | Rubber Seat | Rubber |

Dimensions:

| 117 | |||||||

| Size | A | B | C | D | E | F | G |

| 1/2" | 2.165 | 1.673 | 3.543 | 0.583 | 0.512 | 0.63 | 1.008 |

| 3/4" | 2.854 | 2.028 | 4.469 | 0.748 | 0.748 | 0.878 | 1.173 |

| 1" | 3.386 | 2.244 | 4.469 | 0.945 | 0.866 | 1.13 | 1.331 |

Features:

Solder - Two-Pieces Body - Full Port - Blowout-Proof Stem - Adjustable Stem Packing Nut - PTFE Seats - with Side Drain Port - Lever Handle

NSF/ANSI 61-8

600 PSI WOG Rate

Drain Port Allows Draining of the Non-Pressure Side of the Valve When Closed

Maximum Working Temperature: 300°F (148.8°C)

Conforms to MSS SP-110

Solder ends comply with ANSI B16.18

Company Profile:

Ningbo Huaping Metalwork Co.,Ltd is strong on mass production of excellent processing quality with advanced production technology.300 tons of products are turned out every month to fill large orders and more than 25 types of samples can be developed out within 1 month. We maintain good quality by handling all production in-house, and our inspectors check every valve on site.

We own independent import & export right. So far, 90% of our goods are exported to North America and European countries. Most of our valves are tested and certified by CSA, UL. FM,cUPC,NSF, EN 331 and system certification of ISO9001:2008, etc.

Machining Quality Control

• Self-check in machining process includes 1st article inspection and in-process inspetion(record the data of product every hour).

• Quality inspector performs several time?stour inspection and record the result as well.

In-coming Materials Inspection

• All components made in-house or outsourced are inspected before coming into components warehouse.

Assembly Line Quality Control

• The first batch of selected products are assembled and inspected by assembly worker and record is available.

• Tour inspector performs several times check at the assembly line and record the data.

• Worker performs visual check at the appearance of products.

Leakage Testing

• All casting parts and assembly products are under 100% leakage test.