Brass Gas Ball Valve Flare*Female

| Min. Order: | 1000 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Manual Two Piece Lead Free Brass Ball Valve, Threaded Brass Ball Valve, Brass Gate Valve Threaded, CSA Approved Brass Gas Ball Valve, 600WOG Pressure Lead Free Brass Ball Valve |

Product Detail

| Model No.: | 1022 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Manual |

| Standard or Nonstandard: | Standard |

| Pressure: | Medium Pressure |

| Structure: | Ball |

| Material: | Brass |

| Temperature of Media: | Normal Temperature |

| Media: | Gas |

| Brand Name: | Huaping |

| Power:: | Manual |

| port size:: | full port |

| Pressure:: | 600WOG |

| Certification:: | CSA |

| Material:: | Brass |

| Media:: | Gas |

| Structure:: | Ball |

| Packing: | According To Customer |

| Delivery Date: | 45day |

Product Description

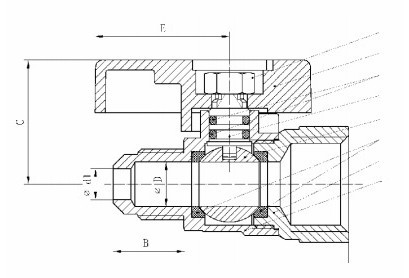

Part Name:Brass Gas Ball Valve-Falre*Female

• 1. CSA Certified - 1/2 PSI for Indoor Appliance Connections per ANSI Z21.15 & CGA9.1

• 2. CSA Certified - 5 PSI for Indoor Shutoff Per CGA91-002& ASME B16.44

• 3. 600 PSI WOG Rated

• 4. Threaded ends comply with ANSI B1.20.1

• Material List

| Item | Part | Material |

| 1 | Body | Brass |

| 2 | End Cap | Brass |

| 3 | Ball Seat | PTFE |

| 4 | Ball | Brass |

| 5 | Stem | Brass |

| 6 | O-ring | NBR |

| 7 | Lever Handle | Aluminum |

| 8 | Stem Nut | Steel |

• Dimension

| 1022 | ||||||

| Size | A | B | C | d1 | D | E |

| 3/8″Flare x 1/2″Female 5/8-18UNF Flare Thread 9/1 6-24UNEF Fine Flare Thread | 2.114 | 0.618 | 1.138 | 0.281 | 0.394 | 1.185 |

| 1/2″Flare x 1 /2″Female | 2.323 | 0.748 | 1.138 | 0.394 | 0.394 | 1.185 |

| 5/8″Flarex 1 /2″Female | 2.520 | 0.878 | 1.295 | 0.500 | 0.591 | 1.185 |

| 1/2″Flare x 3/4″Female | 2.343 | 0.748 | 1.098 | 0.394 | 0.394 | 1.185 |

| 5/8″Flare x 3/4″Female15/ 16-16UN FlareThread 7/8 -14UNF Flare Thread | 2.661 | 0.878 | 1.295 | 0.500 | 0.591 | 1.185 |

• company information

Ningbo Huaping Metalwork Co.,Ltd is specialized in manufacturing BRASS & BRONZE valve and OEM parts with imported automatic valve production machine and CNCs. We own 300 imployees working in an area of 40,000 square meters. We earn good reputation since we exported our quality goods from 2003.

• Material Control

• Sampling inspection is performed towards each batch of material,using ARL spectrum analyzer.

• Machining Quality Control

• Self-check in machining process includes 1st article inspection and in-process inspetion(record the data of product every hour).

• Quality inspector performs several time?stour inspection and record the result as well.

• In-coming Materials Inspection

• All components made in-house or outsourced are inspected before coming into components warehouse.

• Assembly Line Quality Control

• The first batch of selected products are assembled and inspected by assembly worker and record is available.

• Tour inspector performs several times check at the assembly line and record the data.

• Worker performs visual check at the appearance of products.

• Leakage Testing

• All casting parts and assembly products are under 100% leakage test.

• Final Inspection before Delivery

• Inspector performs sampling check from the packaged products, and qualified products are allowed for delivery from finished products warehouse.