Quarter Turn Boiler Drain Valve

| Min. Order: | 1000 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Manual Two Piece Lead Free Brass Ball Valve, Threaded Brass Ball Valve, Brass Gate Valve Threaded, CSA Approved Brass Gas Ball Valve, 600WOG Pressure Lead Free Brass Ball Valve |

Product Detail

| Model No.: | 1060 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Manual |

| Standard or Nonstandard: | Standard |

| Pressure: | Medium Pressure |

| Structure: | Ball |

| Material: | Brass |

| Temperature of Media: | Normal Temperature |

| Media: | Water |

| Brand Name: | Huaping |

| Type:: | Valve |

| certificate:: | NSF |

| power: | Manual |

| Port Size:: | thread |

| Pressure:: | 125PSI WOG |

| Packing: | According To Customer |

| Delivery Date: | 45day |

Product Description

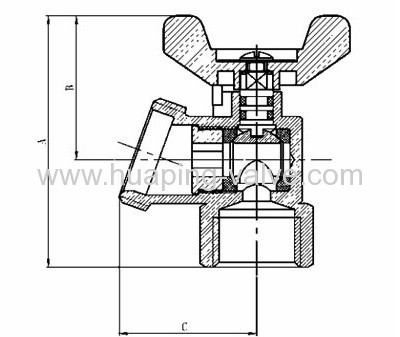

product name Quarter-Turn Boiler Drain Valve

• feature

• 1.Meet NSF approved low lead standards

• 2.Easy Quarter Turn Operation

• 3.Maximun 125PSI working pressure

• 4.Chrome Plated Brass Ball

• 5.Teflon Seats

• 6.3/4" Hose Thread Outlet

• 7.Pipe Thread Comply with ANSI B1.20.1

• 8.Hose Thread Comply with ANSI B1.20.7

• 9.Solder Ends Comply with ANSI B16.18

• Material List

| Item | Part | Material |

| 1 | Body | Brass |

| 2 | End Cap | Brass |

| 3 | Ball Seat | PTFE |

| 4 | Ball | Brass |

| 5 | Stem | Brass |

| 6 | O-ring | NBR |

| 7 | Bolt | Nickle Plating steel |

| 8 | Handle | Aluminum |

| 9 | Nameplate | Aluminum |

Dimension

| Description | Dimension | |||

| Boiler Drain FIP to hose | Size | A | B | C |

| 1/2' | 2.157 | 1.134 | 1.307 | |

| 3/4' | 2.217 | 1.134 | 1.307 | |

• Features

• 1. High quality.

• 2. Compact and optimized structure.

• 3. Good price with professional service.

• 4. Full type of items.

• 5. Customized service.

• 6. Prompt delivery time.

Material Control

• Sampling inspection is performed towards each batch of material,using ARL spectrum analyzer.

Machining Quality Control

• Self-check in machining process includes 1st article inspection and in-process inspetion(record the data of product every hour).

• Quality inspector performs several time?stour inspection and record the result as well.

In-coming Materials Inspection

• All components made in-house or outsourced are inspected before coming into components warehouse.

Assembly Line Quality Control

• The first batch of selected products are assembled and inspected by assembly worker and record is available.

• Tour inspector performs several times check at the assembly line and record the data.

• Worker performs visual check at the appearance of products.

Leakage Testing

• All casting parts and assembly products are under 100% leakage test.

Final Inspection before Delivery

• Inspector performs sampling check from the packaged products, and qualified products are allowed for delivery from finished products warehouse.