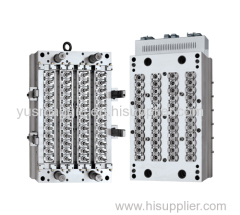

72 cavities PET preform mould

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/A, T/T, WU |

| Supply Ability: | 400 set/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Preform Mould, Plastic Cap/closure Mould, Bottle Blow Mould, Plastic Injection Mould |

Product Detail

| Model No.: | 72 cavities PET preform mould |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 400 set/year |

| Packing: | plywood box |

| Delivery Date: | 55days |

Product Description

72 cavities PET preform mould specification:

1.72 cavities PET preform mould neck finishes:38mm,30/25,29/25,26/22,1810,

1881,1716 etc.

2.72 cavities PET preform mould core,cavity and neck screw steel: Germany 2316

3.72 cavities PET preform mould base steel:P20 and 50#

4.72 cavities PET preform mould valve pin steel: SKD 51 from Japan

5.72 cavities PET preform mould valve pin heat Isolation pad:America Dupont can withstand 350 degree temperature

6.72 cavities PET preform mould hot runner nozzle:America Beryllium Copper

7.72 cavities PET preform mould applications include:Aseptic,cole fill,hot fill,CSD,

dry food,snacks jars and cosmetic bottles.

72 cavities PET preform mould design:

Interchangeable parts for every cavity.

Cam roller design for thread splits helps operator maintenance freely.

Perfectly balanced hot runners ensure uniform melt flow and pressure in all cavities.

Good quality cooling system for optimum production level, shorten the cycle time of products.

Individual dual tapers locking design for thread splits,lock ring and cavity that reduce moulds wear.

Contact:daelong4 at hotmail dot com

.jpg)