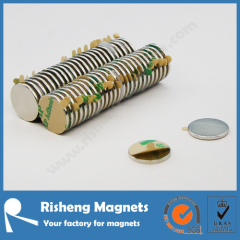

3M adhesive neodymium disc magnets

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000 piece one year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Shape: | Ball |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Grade:: | N35-52,M,H,SH,UH,EH |

| Packing:: | vacuum encapsulation |

| size:: | D13*2,D13*1,D12*3,D10*1,D10*1.5,D10*0.6,D10*0.75mm |

| apply: | Packaging, suction cups, horn, etc |

| Production Capacity: | 1000000 piece one year |

| Packing: | vacuum encapsulation, plastic tubes, etc |

| Delivery Date: | According to the actual number of delivery date |

Product Description

product name 3M adhesive neodymium disc magnets

feature

1.Grade:N35-52,M,H,SH,UH,EH

2.size:D13*2,D13*1,D12*3,D10*1,D10*1.5,D10*0.6,D10*0.75mm

3.Packing:vacuum encapsulation

4.Coating: we can meet customers' different coatings, such as nickel, nickel, copper, nickel, zinc, gold, silver, and the passivation, black epoxy resin, etc., all of our coating used in strong neodymium magnets are in line with international environmental protection standard of ROHS

Applications of Neodymium

Magnetic

separators,

linear actuators,

microphone assemblies,

servo motors,

DC motors (automotive starters),

computer rigid disc drives,

printers,

speakers.

Lifter

Magnetizing and Handling

Neodymium

magnets are very brittle and very strong magnetically. Therefore, it is crucial

to handle these magnets with extreme care to avoid personal injury and damage to

the magnets. Fingers can be severely pinched between attracting magnets. Magnets

can chip if allowed to jump at an attracting object. It is highly recommended

that when constructing rare earth magnetic assemblies, they be magnetized after

assembly..

factory picture