Super Strong Neodymium Block Magnet for Wind Generator

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000 piece one year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Motor Magnet |

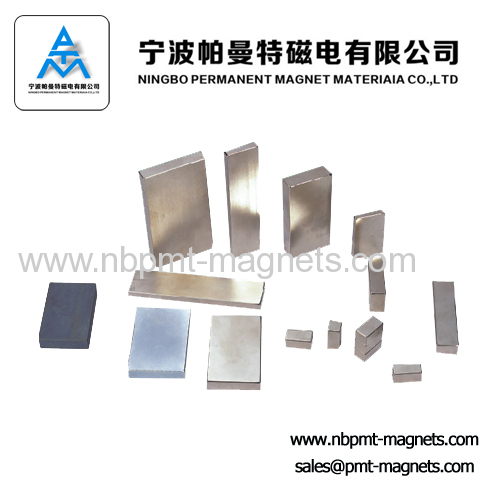

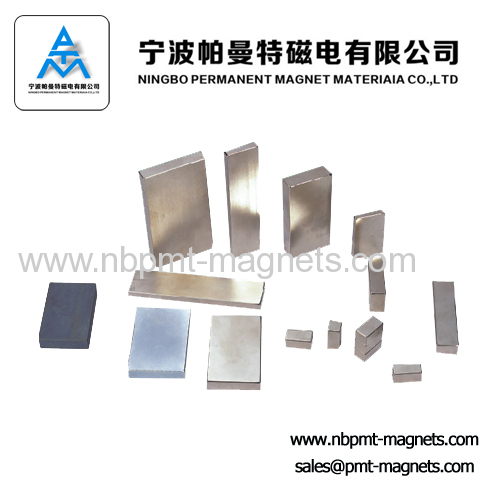

| Shape: | Block |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| size:: | According to customer's requirement |

| Grade:: | N35-52,M,H,SH,UH,EH |

| Coating: | NiCuNi, Zn, Black Epoxy, and etc. |

| Material::: | Neodymium Magnet |

| Production Capacity: | 1000000 piece one year |

| Packing: | According to the practical mode of transportation decided to packing |

| Delivery Date: | According to the actual number of delivery date |

Product Description

product name Super Strong Neodymium Block Magnet for Wind Generator

Neodymium (NdFeB) magnets, the third generation of rare earth permanent Neodymium magnet, are composed of Neodymium, Iron, Boron and a few transition metals. They have high remanence, high coercive force, high energy product, and high performance /cost. Currently Neodymium (NdFeB) magnets are the strongest magnets available in the world.

Manufacturing Process of Rare Earth Neodymium Magnets

Neodymium, Iron, Boron and a few transition metals will be made into the NdFeB (Neodymium) powder, then fine NdFeB powder will be compacted in a die and sintered, fusing the powder into a solid material. There are 2 forms of pressing: die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances.

Machining & Tolerance of Rare Eart Neodymium Magnets

Generally, (Neodymium) NdFeB magnets must be machined using diamond-grinding techniques. Sometimes, machining operations may be performed on Neodymium (NdFeB) materials using carbide tools, but surface finishes thus obtained may be less than optimal. The Standard tolerances for NdFeB (Neodymium) magnets are +/- 0.1mm for ground dimensions, but sticter tolerances are possible if specially required.

Surface treatments of Rare Earth Neodymium Magnets

The corrosion resistance of NdFeB (Neodymium) magnets is considered poor. Surface coating or plating is therefore highly recommended for NdFeB (Neodymium) magnets. All kinds of surface coating are available, like Nickel, Zn, Ni-Cu-Ni, Gold, Silver, Sn, Chrome and etc.

Application of Rare Earth Neodymium Magnets

Widely used in automobiles, mobile phones, digital cameras, jewelry, clothing, all kinds of hardware accessories, electrical, laser heads, toys, gifts, speakers, packing, leather goods, medical equipment and adverying, Switchboard, voice coil motors (VCM's) in hard disk drives, high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors, loudspeakers etc.