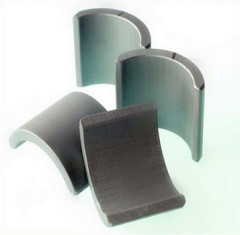

Super Strong Permanent Neodymium Magnet in Arc

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000 piece |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Grade:: | N35-52,M,H,SH,UH,EH |

| size: | According to customer requirements |

| cladding material: | Nickel, nickel and copper, nickel, zinc, gold, silver, and the passivation, black epoxy resin |

| apply: | motor |

| shape: | Arc |

| Production Capacity: | 1000000 piece |

| Packing: | According to the practical mode of transportation decided to packing |

| Delivery Date: | According to the actual number of delivery date |

Product Description

product name Super Strong Permanent Neodymium Magnet in Arc / Segment Shapes

feature

1.applied:industrial magnets

2.shape:Arc

feature

1.applied:industrial magnets

2.shape:Arc

3.Grade:N35-52,M,H,SH,UH,EH

5.size:According to customer requirements

6.apply :motor

7.material :Neodymium Magnets

8.cladding material :Nickel, nickel and copper, nickel, zinc, gold, silver, and the passivation, black epoxy resin

9.Max Working Temperature: 80 ℃

8.cladding material :Nickel, nickel and copper, nickel, zinc, gold, silver, and the passivation, black epoxy resin

9.Max Working Temperature: 80 ℃

Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Maximum Working Temperature |

Br | Hcb | Hcj | (BH)max | Tw | |

mT | kA/m | kA/m | kJ/m3 | ||

[kGs] | [kOe] | [kOe] | [MGOe] | ||

N35 | 1170-1220 | ≥868 | ≥955 | 263-287 | 80° |

[11.7-12.2] | [≥10.9] | [≥12] | [33-36] | ||

N38 | 1220-1250 | ≥899 | ≥955 | 287-310 | 80° |

[12.2-12.5] | [≥11.3] | [≥12] | [36-39] | ||

N40 | 1250-1280 | ≥907 | ≥955 | 302-326 | 80° |

[12.5-12.8] | [≥11.4] | [≥12] | [38-41] | ||

N42 | 1280-1320 | ≥915 | ≥955 | 318-342 | 80° |

[12.8-13.2] | [≥11.5] | [≥12] | [40-43] | ||

N45 | 1320-1380 | ≥923 | ≥955 | 342-366 | 80° |

[13.2-13.8] | [≥11.6] | [≥12] | [43-46] | ||

N48 | 1380-1420 | ≥923 | ≥955 | 366-390 | 80° |

[13.8-14.2] | [≥11.6] | [≥12] | [46-49] | ||

N50 | 1400-1450 | ≥796 | ≥876 | 382-406 | 80° |

[14.0-14.5] | [≥10.0] | [≥11] | [48-51] | ||

N52 | 1430-1480 | ≥796 | ≥876 | 398-422 | 80° |

[14.3-14.8] | [≥10.0] | [≥11] | [50-53] | ||

30M | 1080-1130 | ≥805 | ≥1114 | 223-247 | 100° |

[10.8-11.3] | [≥10.1] | [≥14] | [28-31] | ||

33M | 1130-1170 | ≥836 | ≥1114 | 247-263 | 100° |

[11.3-11.7] | [≥10.5] | [≥14] | [31-33] | ||

35M | 1170-1220 | ≥868 | ≥1114 | 263-287 | 100° |

[11.7-12.2] | [≥10.9] | [≥14] | [33-36] | ||

38M | 1220-1250 | ≥899 | ≥1114 | 287-310 | 100° |

[12.2-12.5] | [≥11.3] | [≥14] | [36-39] | ||

40M | 1250-1280 | ≥923 | ≥1114 | 302-326 | 100° |

[12.5-12.8] | [≥11.6] | [≥14] | [38-41] | ||

42M | 1280-1320 | ≥955 | ≥1114 | 318-342 | 100° |

[12.8-13.2] | [≥12.0] | [≥14] | [40-43] | ||

45M | 1320-1380 | ≥995 | ≥1114 | 342-366 | 100° |

[13.2-13.8] | [≥12.5] | [≥14] | [43-46] | ||

48M | 1370-1430 | ≥1027 | ≥1114 | 366-390 | 100° |

[13.7-14.3] | [≥12.9] | [≥14] | [46-49] | ||

50M | 1400-1450 | ≥1033 | ≥1114 | 382-406 | 100° |

[14.0-14.5] | [≥13.0] | [≥14] | [48-51] | ||

35H | 1170-1220 | ≥868 | ≥1353 | 263-287 | 120° |

[11.7-12.2] | [≥10.9] | [≥17] | [33-36] | ||

38H | 1220-1250 | ≥899 | ≥1353 | 287-310 | 120° |

[12.2-12.5] | [≥11.3] | [≥17] | [36-39] | ||

40H | 1250-1280 | ≥923 | ≥1353 | 302-326 | 120° |

[12.5-12.8] | [≥11.6] | [≥17] | [38-41] | ||

42H | 1280-1320 | ≥955 | ≥1353 | 318-342 | 120° |

[12.8-13.2] | [≥12.0] | [≥17] | [40-43] | ||

45H | 1320-1360 | ≥963 | ≥1353 | 342-366 | 120° |

[13.2-13.6] | [≥12.1] | [≥17] | [43-46] | ||

48H | 1370-1430 | ≥995 | ≥1353 | 366-390 | 120° |

[13.7-14.3] | [≥12.5] | [≥17] | [46-49] | ||

35SH | 1170-1220 | ≥876 | ≥1592 | 263-287 | 150° |

[11.7-12.2] | [≥11.0] | [≥20] | [33-36] | ||

38SH | 1220-1250 | ≥907 | ≥1592 | 287-310 | 150° |

[12.2-12.5] | [≥11.4] | [≥20] | [36-39] | ||

40SH | 1250-1280 | ≥939 | ≥1592 | 302-326 | 150° |

[12.5-12.8] | [≥11.8] | [≥20] | [38-41] | ||

42SH | 1280-1320 | ≥987 | ≥1592 | 318-342 | 150° |

[12.8-13.2] | [≥12.4] | [≥20] | [40-43] | ||

45SH | 1320-1380 | ≥1003 | ≥1592 | 342-366 | 150° |

[13.2-13.8] | [≥12.6] | [≥20] | [43-46] | ||

28UH | 1040-1080 | ≥764 | ≥1990 | 207-231 | 180° |

[10.4-10.8] | [≥9.6] | [≥25] | [26-29] | ||

30UH | 1080-1130 | ≥812 | ≥1990 | 223-247 | 180° |

[10.8-11.3] | [≥10.2] | [≥25] | [28-31] | ||

33UH | 1130-1170 | ≥852 | ≥1990 | 247-271 | 180° |

[11.3-11.7] | [≥10.7] | [≥25] | [31-34] | ||

35UH | 1170-1220 | ≥860 | ≥1990 | 263-287 | 180° |

[11.7-12.2] | [≥10.8] | [≥25] | [33-36] | ||

38UH | 1220-1250 | ≥876 | ≥1990 | 287-310 | 180° |

[12.2-12.5] | [≥11.0] | [≥25] | [36-39] | ||

40UH | 1250-1280 | ≥899 | ≥1990 | 302-326 | 180° |

[12.5-12.8] | [≥11.3] | [≥25] | [38-41] | ||

28EH | 1040-1080 | ≥780 | ≥2388 | 207-231 | 200° |

[10.4-10.8] | [≥9.8] | [≥30] | [26-29] | ||

30EH | 1080-1130 | ≥812 | ≥2388 | 223-247 | 200° |

[10.8-11.3] | [≥10.2] | [≥30] | [28-31] | ||

33EH | 1130-1170 | ≥876 | ≥2388 | 247-271 | 200° |

[11.3-11.7] | [≥10.5] | [≥30] | [31-34] | ||

35EH | 1170-1220 | ≥876 | ≥2388 | 263-287 | 200° |

[11.7-12.2] | [≥11.0] | [≥30] | [33-36] | ||

38EH | 1220-1250 | ≥899 | ≥2388 | 287-310 | 200° |

[12.2-12.5] | [≥11.3] | [≥30] | [36-39] | ||

28AH | 1040-1080 | ≥787 | ≥2624 | 207-231 | 220° |

[10.4-10.8] | [≥9.9] | [≥33] | [26-29] | ||

30AH | 1080-1130 | ≥819 | ≥2624 | 223-247 | 220° |

[10.8-11.3] | [≥10.3] | [≥33] | [28-31] | ||

33AH | 1130-1170 | ≥843 | ≥2624 | 247-271 | 220° |

[11.3-11.7] | [≥10.6] | [≥33] | [31-34] |