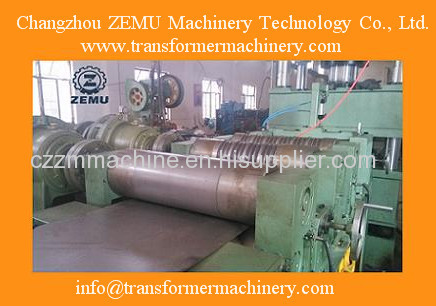

1.General Description of Oil Cooling Radiator for Transformer Production Line

1) Our oil colling for transformer production line is designed on the basis of technology from international.

2) Oil colling radiator of different widths (520mm, 480mm, 320 or 310 mm) can be produced by it

3) Size changing on the roll forming machine is realized by hydraulic drive, easy and convenient

2.Build up of Oil Cooling Radiator for Transformer Production Line

1) Hydraulic expansion decoiler

2) Roll forming machine

3) Transmitting table

4) Hydraulic press, special punching, folding and cutting mould

5) Pneumatic system

6) Hydraulic system

7) PLC control system

8) Run-out table.

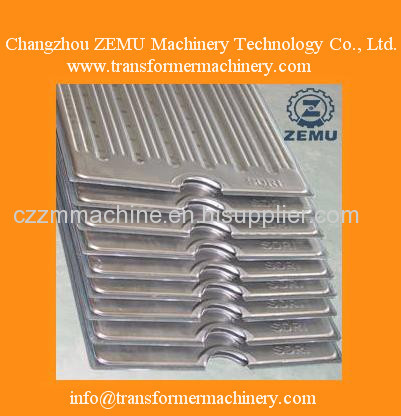

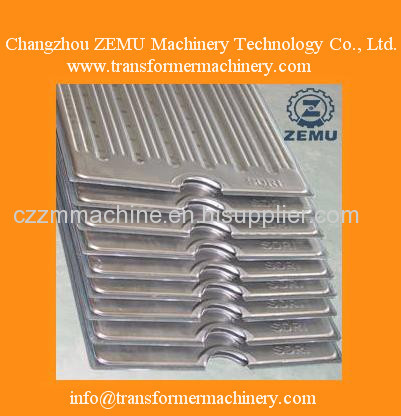

3.Main Technical Data of Oil Cooling Radiator for Transformer Production Line

1) Length range of fin plate: 400-4000mm

2) Width of fin plate: 520, 480, 320 mm

3) Production speed: 120 pieces per minute (when fin length is 1500mm)

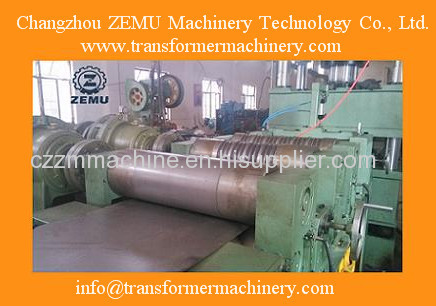

4.General Description of Oil Cooling Radiator Welding Line

1) This oil cooling radiator welding line is used to automatically weld the radiator

fins for high voltage power transformers.

2) The size of fin is 500~45000mm long, 310~550mm wide (adjustable).

3) The raw material is ST12, 1.0mm thick.

4) The welded fin should be airproof, and should be no-leakage tried by 0.25MPa pressure for 20 minutes.

5) According to different requirements, the line may have different configurations.

Our pictures of transformer radiator machine