D2 Alloy Steel Plate with Test Certificate

700.0~1100.0 USD

| Min. Order: | 5 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 2000 Metric Ton/Metric Tons per Month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Drill Pipe, Tinplate, Galvanized Coil, Steel Pipe, Round Steel Bar |

Product Detail

| Model No.: | D2 |

|---|---|

| Means of Transport: | Ocean |

| Steel Grade:: | D2 |

| Standard:: | AISI,ASTM,BS,DIN,GB,JIS |

| Brand Name:: | JIANHUI |

| Special Use: | High-strength Steel Plate |

| Alloy Or Not:: | Non-alloy |

| Technique:: | Hot Rolled |

| Model Number:: | D2 |

| Place of Origin:: | Henan, China (Mainland) |

| Application:: | : Container Plate |

| Width: | 1000-3000mm |

| Production Capacity: | 2000 Metric Ton/Metric Tons per Month |

| Packing: | According to the customer request |

| Delivery Date: | 25--30 days |

Product Description

D2 Alloy Mold SteelPlate

Similar Grade

Cr12Mo1V1 (GB)

Brief Introduction

D2 is High carbon high chromium mold Steel ,belong to ledeburitic steel . D2 have higher quenching degree , wear resistanceand high temperature oxidation resistance .

Chemical Compostion

C:1.40~1.60

Si≤0.60

Mn≤0.60

S ≤0.030

P ≤0.030

Cr:11.00~13.00

V≤1.10

Co≤1.00

Mo:0.70~1.20

Delivery Condition

Quenching+Tempering or as yourrequest

Payment Term

T/T & L/C

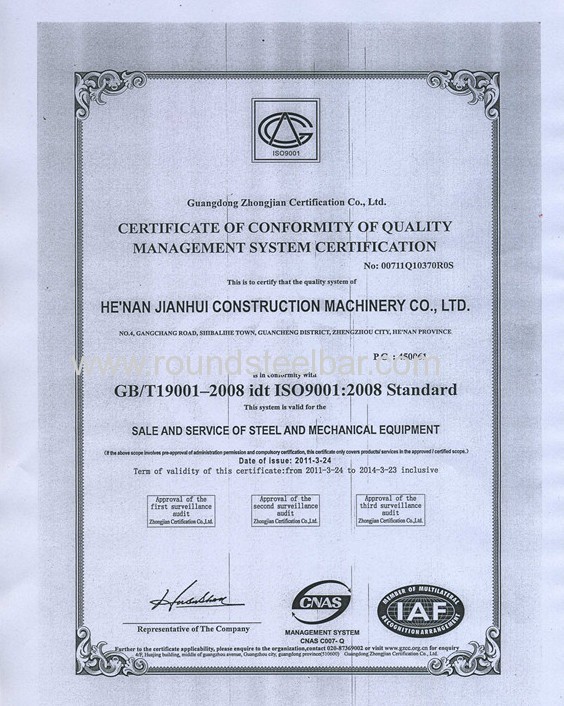

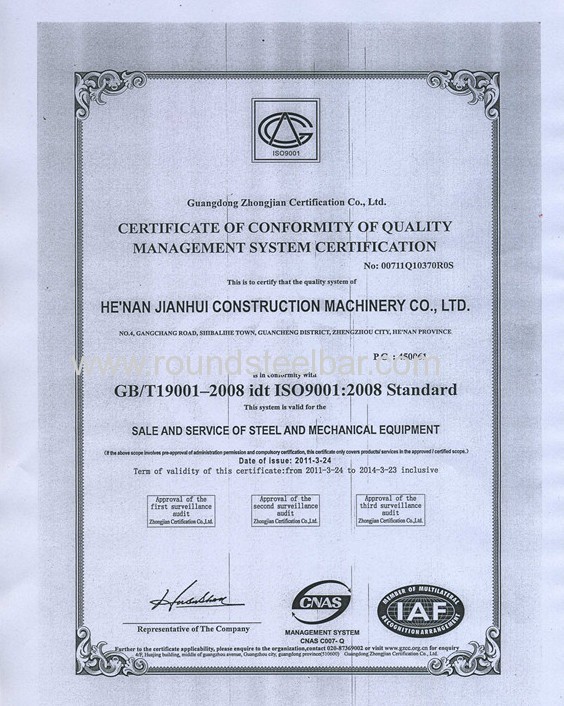

ceritificate

| Equivalent grades | ||||

| GB | DIN | AISI | JIS | BS |

| Cr12Mo1V1 | 1.2379 | D2 | SKD11 | BD2 |

| Chemical composition | |||||||

| C | Si | Mn | Cr | P | S | V | Mo |

| 1.50-1.60 | 0.10-0.40 | 0.15-0.45 | 11.00-12.50 | 0.03MAX | 0.03MAX | 0.90-1.10 | 0.60-0.80 |

| Available size | |||||||||

| Round Bar Diameter 60mm - 800mm | |||||||||

| Flat Bar 25-400mm*200-800mm |

| Surface condition | |||||||||

| Black surface/ Grinded/ Machined |

| Hardness | |||||||||

| HB225MAX |

| Characteristics | |||||||||

Cold Work Alloy Steel Plate, D2 Alloy Steel Plateis of Very high resistance against abrasive and adhesive wear due to a high volume of hard carbides in the steel matrix moderate machinability, good dimensional stability, toughness and through harden ability |

| Heat treatment | |||||||||

| Hardening Harden from a temperature of 1000-1040 Celsius degree followed by oil, warm bath (500-550 Celsius degree , cooling bath or air. Hardness after quenching is 62-64 HRC. Tempering Tempering temperature: 150-550 Celsius degree |