integral spiral blade stabilizer

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 1000 Piece/Pieces per Month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Drill Pipe, Tinplate, Galvanized Coil, Steel Pipe, Round Steel Bar |

Product Detail

| Model No.: | API SPEC7-1 Well Drilling |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Certification: | ISO |

| Type:: | Kelly bar |

| Material:: | : High Manganese Steel |

| Machine Type: | Drilling Equipment |

| Processing Type: | Forging |

| Use: | Well Drilling |

| Port: | Tianjin |

| Minimum Order Quantity: | 1 Piece/Pieces |

| Supply Ability: | 1000 Piece/Pieces per Month |

| Packaging Details: | as request |

| Production Capacity: | 1000 Piece/Pieces per Month |

| Packing: | According to the customer request |

| Delivery Date: | 20-30 days |

Product Description

Steel forged stabilizer

1.raw material: AISI 4145H MOD

2.quality: API SPEC7-1

3.hardfacing types for stabilizers are: HF1000,HF2000,HF3000,HF4000.

4.stabilizers can be designed according to customers' special requirements.

Quality Policy

Strive for Perfection, Build Competitive products;

Pursue of excellence, Create First-class brand.

jianhui offers several options for IBS, in both alloy steel and non-magnet materials:

●Spiral Integral Blade Stabilizer;

●Straight Integral Blade Stabilizer;

●Non-Magnet Integral Blade Stabilizer;

When Ordering Please Specify:

●Hole size or required blade O.D.;

●Number of blades required (3 or 4 are standard styles);

●Straight or spiral blades;

●Hardfacing type ;

●Top and Bottom Connections;

●Body diameter required;

●String or Near Bit application;

●Alloy steel or non-magnet materials ;

●Special features SRG on connections, bored for float etc.

Specifications - Integral Blade Stabilizer

Bit size | O.D. | O.D. of body | I.D. (mm) | Length (mm) | String type connections | Near bit type connections | ||

Top | Down | Top | Down | |||||

6 | 152.2 | 121 | 51 | 1200 | NC38 | NC38 | NC38 | 3 1/2 REG |

6 1/4 | 158.7 | 121 | 51 | 1200 | NC38 | NC38 | NC38 | 3 1/2 REG |

6 1/2 | 165.1 | 121 | 51 | 1200 | NC38 | NC38 | NC38 | 3 1/2 REG |

7 1/2 | 190.5 | 159 | 57 | 1600 | NC46 | NC46 | NC46 | 4 1/2 REG |

7 7/8 | 200 | 159 | 57 | 1600 | NC46 | NC46 | NC46 | 4 1/2 REG |

8 1/2 | 215.2 | 165 | 71 | 1800 | NC50 | NC50 | NC46 | 4 1/2 REG |

9 1/2 | 241.3 | 197 | 71 | 1800 | NC50 | NC50 | NC50 | 6 5/8 REG |

12 1/4 | 311.2 | 203 | 76 | 1800 | 6 5/8 REG | 6 5/8 REG | 6 5/8 REG | 6 5/8 REG |

16 | 406 | 229 | 76 | 2200 | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG |

17 1/2 | 444.5 | 241.3 | 76 | 2200 | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG |

24 | 609.6 | 241.3 | 76 | 2540 | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG |

26 | 660.4 | 241.3 | 76 | 2540 | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG |

28 | 711.2 | 254 | 76 | 2540 | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG | 7 5/8 REG |

Cetification

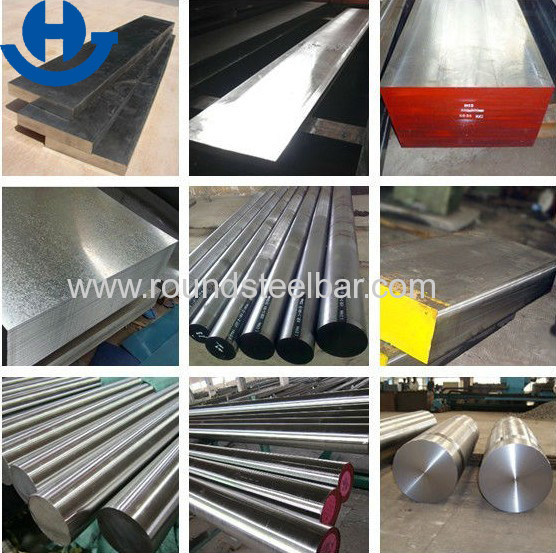

<FORM method=post name=form1 action=http://account.hisupplier.com/user/inquiry.htm target=_blank>Production Equipment

Processing Equipment

Black Steels

Peeling Steels

finished steel

Testing Equipment