Petroleum equipment Drill pipe

| Min. Order: | 1 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 1000 Ton/Tons per Month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

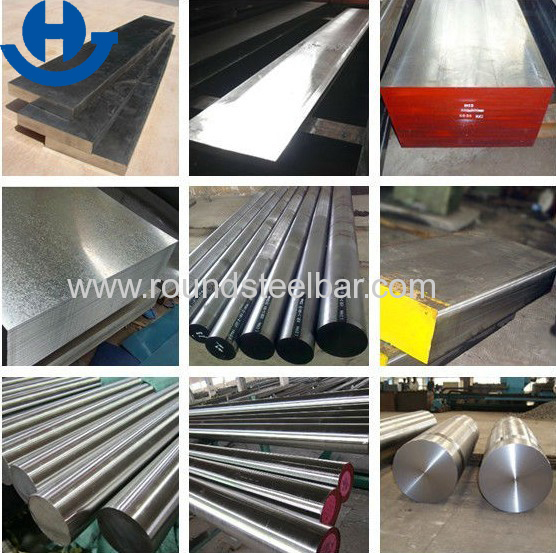

| Main Products: | Drill Pipe, Tinplate, Galvanized Coil, Steel Pipe, Round Steel Bar |

Product Detail

| Model No.: | API Spec 7 |

|---|---|

| Means of Transport: | Ocean, Land |

| Material: | Carbon Steel |

| Processing Type: | Forging |

| Port:: | Tianjin |

| Minimum Order Quantity:: | 5 ton |

| Place of Origin: | Henan, China (Mainland) |

| Machine Type: | : Drilling Tool |

| Certification: | API |

| technology: | Forging |

| Type: | Drill Pipe |

| Use: | Well Drilling |

| Production Capacity: | 1000 Ton/Tons per Month |

| Packing: | According to the customer request |

| Delivery Date: | 20-30 days |

Product Description

We can supply various sizes of Grade Q235B Steel H-beams on the basic of different Standards, Our company has been exporting our high quality products with very competitive prices to Middle East, Southeast Asia, South America for many years, and have won a lot of our customers' trust and support. And now our sales market is extending to the whole world. any necessary ,connect with us ,

E-mail: jianhuisales@hotmail.com

Tel: 86-371-86059106

The principle of our company is based on the quality of survival. With advanced technology and scientific management, our company develops with reputations for providing quality products and best service.

Specifications

1.petroleum equipment drill pipe

2.With API and ISO9001

3.Metal sealed journal bearing

4.Fast drilling rating

5.Cheap

| Packaging Details: | bundled with steel stripe |

|---|---|

| Delivery Detail: | 30days |

Size Designation | Nominal | Calculated Weight Wpe | Grade | Wall Thickness | Upset Ends, for Weld-on Tool Joins(see note) | |||

in. | mm | Weight | lb/ft | kg/m | in. | mm | ||

2 3/8 | 60.3 | 6.65 | 6.26 | 9.32 | E,X,G,S | 0.28 | 7.11 | EU |

2 7/8 | 73 | 10.4 | 9.72 | 14.48 | E,X,G,S | 0.362 | 9.19 | EU IU |

3 1/2 | 88.9 | 9.5 | 8.81 | 13.12 | E | 0.254 | 6.45 | EU IU |

3 1/2 | 88.9 | 13.3 | 12.31 | 18.34 | E,X,G,S | 0.368 | 9.35 | EU IU |

3 1/2 | 88.9 | 15.5 | 14.63 | 21.79 | E | 0.449 | 11.4 | EU IU |

3 1/2 | 88.9 | 15.5 | 14.63 | 21.79 | X,G,S | 0.449 | 11.4 | EU IEU |

4 | 101.6 | 14 | 12.93 | 19.26 | E,X,G,S | 0.33 | 8.38 | EU IU |

4 1/2 | 114.3 | 13.75 | 12.24 | 18.23 | E | 0.271 | 6.88 | EU IU |

4 1/2 | 114.3 | 16.6 | 14.98 | 22.31 | E,X,G,S | 0.337 | 8.56 | EU IEU |

4 1/2 | 114.3 | 20 | 18.69 | 27.84 | E,X,G,S | 0.43 | 10.92 | EU IEU |

5 | 127 | 16.25 | 14.87 | 22.15 | X,G,S | 0.296 | 7.52 | IU |

5 | 127 | 19.5 | 17.93 | 26.71 | E | 0.362 | 9.19 | IEU |

5 | 127 | 19.5 | 17.93 | 26.71 | X,G,S | 0.362 | 9.19 | EU IEU |

5 | 127 | 25.6 | 24.03 | 35.79 | E | 0.5 | 12.7 | IEU |

5 | 127 | 25.6 | 24.03 | 35.79 | X,G,S | 0.5 | 12.7 | EU IEU |

5 1/2 | 139.7 | 21.9 | 19.81 | 29.51 | E,X,G,S | 0.361 | 9.17 | IEU |

5 1/2 | 139.7 | 24.7 | 22.54 | 33.57 | E,X,G,S | 0.415 | 10.54 | IEU |

) Made from one piece of AISI 4145H solid bar

2) Formed by hot forged and fully heat-treated

3) All threads are phosphated, copperized or cold worked

4) Fully inspected by an ultrasonic unit (at full length and over full section)

6) Could be coated internally with DPC (equivalent to TK 34) as customer's request that are able to prevent corrosion and extend using time.

3.Standard:

API Spec 7 or SY/T5145

Production Equipment

Processing Equipment

Black Steels

Peeling Steels

finished steel

Testing Equipment