SEAMLESS CARBON STEEL PIPE EN 10216-1 P235TR1

| Min. Order: | 1 Ton |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500 Ton/Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Pipe, ASTM A106 ASTM A53 Gr.B, API 5L X70 Carbon Seamless Pipes X60 X52 X42, API 5L X80 PSL1/PSL2 SMLS LINE PIPES, API 5L PSL2 X56 X60 SEAMLESS SMLS LINE PIPE |

Product Detail

| Model No.: | EN 10216-1 P235TR1 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product Name: | Steel Pipe EN 10216-1 P235TR1 |

| Type: | Seamless |

| OD: | 168.3 |

| WT: | 7.11 |

| Length: | 5-14m 5.8m,6m,11.8m,12m |

| Ends: | PE. BE. Threaded,Grooved,Coupling |

| Surface Treatment: | Bare,Painting black,varnished,galvanized,anti-corrosion 3PE |

| Testing Methods: | Eddy current testing, Hydrostatic testing,NDT |

| Third Party Inspection: | SGS BV MTC |

| Certificates: | ISO,API,CE,PED |

| Production Capacity: | 500 Ton/Month |

| Packing: | in bundles/in loose pieces;wooden cases;in bulk or accrdin to custmrs' requests |

| Delivery Date: | within 30-45 days after receipt of advance payment |

Product Description

QCCO STEEL PIPE Material & Standard

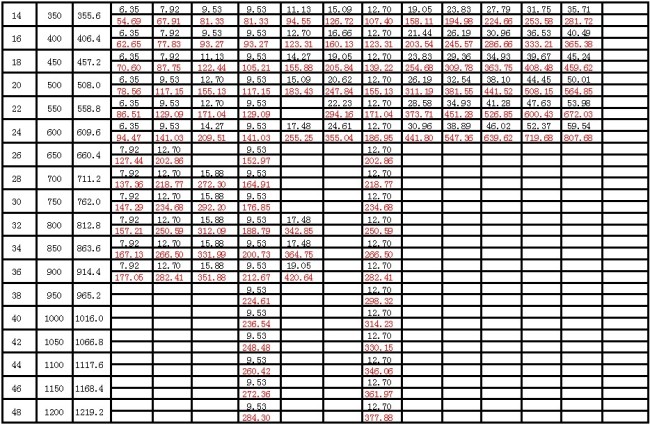

QCCO STEEL PIPE NPS: 21-1524mm

SEAMLESS pipe: from 1/2" to 36"

ERW pipe: from 1/2" to 20"

LSAW pipe: from 16" to 60"

SSAW pipe: from 4" to 80"

Pipe Ends: Plain/Beveled,plastic caps on both ends,cut quare,grooved,threaded and coupling,etc

Surface Treatment:Black painting,Varnished, Galvanized, Anti-Corrosion 3PE coated

HIC & SSCC test report

Best quality (mother pipes from TPCO/Hengsteel(Hengyang valin)/Baosteel/Baotou Steel)

Large stock of steel pipes(150,000 Tons) for Speedy Delivery

Sample can be sent for testing

Customized design available

THK: 1-60mm SCH10 SCH20 SCH30 STD SCH40 SCH60 XS SCH80 SCH100 SCH120 SCH140 SCH160 XXS

LENGTH: 5.8m 6m 11.8m 12m,Random Length or acc. to customers requirment

TESTING METHODS: NDT UT RT etc.

PACKAGING: plastic caps on both ends,pipes of 6" and under 6" bundled with steel belts

SEAMLESS STEEL TUBES FOR PRESSURE PURPOSE

EN 10216-1,EN 10216-2 EUROPEAN STANDARD

Application: Boiler tube, Superheater tipe, Air preheating...

Main steel grades:P195,P235,P265,P195GH,P235GH,P265GH,13CrMo4-5,10CrMo9-10

Chemical Composition(%)

Standard | Grade | Chemical composition limits,% | ||||||||||||

C | Si | Mn | P | S | Cr | Mo | Ni | Al | Cu | Nb | Ti | V | ||

EN10216-1 | P195TR1 | ≤0.13 | ≤0.35 | ≤0.70 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | / | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 |

P195TR2 | ≤0.13 | ≤0.35 | ≤0.70 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | ≥0.02 | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 | |

P235TR1 | ≤0.16 | ≤0.35 | ≤1.20 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | / | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 | |

P235TR2 | ≤0.16 | ≤0.35 | ≤1.20 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | ≥0.02 | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 | |

P265TR1 | ≤0.20 | ≤0.40 | ≤1.40 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | / | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 | |

P265TR2 | ≤0.20 | ≤0.40 | ≤1.40 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | ≥0.02 | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 | |

EN10216-2 | P195GH | ≤0.13 | ≤0.35 | ≤0.70 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | ≥0.02 | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 |

P235GH | ≤0.16 | ≤0.35 | ≤1.20 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | ≥0.02 | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 | |

P265GH | ≤0.20 | ≤0.40 | ≤1.40 | ≤0.025 | ≤0.020 | ≤0.30 | ≤0.08 | ≤0.30 | ≥0.02 | ≤0.30 | ≤0.01 | ≤0.04 | ≤0.02 | |

13CrMo4-5 | 0.10~0.17 | ≤0.35 | 0.40~0.70 | ≤0.025 | ≤0.020 | 0.70~1.15 | 0.40~0.60 | ≤0.30 | ≤0.04 | ≤0.30 | / | / | / | |

10CrMo9-10 | 0.08~0.14 | ≤0.50 | 0.30~0.70 | ≤0.025 | ≤0.020 | 2.00~2.50 | 0.90~1.10 | ≤0.30 | ≤0.04 | ≤0.30 | / | / | / | |

Mechanical Properties

Standard | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation(%) | Impact Energy (J) |

EN 10216-1 | P195TR1 | 320~440 | ≥195 | ≥27 | / |

P195TR2 | 320~440 | ≥195 | ≥27 | ≥40 | |

P235TR1 | 360~500 | ≥235 | ≥25 | / | |

P235TR2 | 360~500 | ≥235 | ≥25 | ≥40 | |

P265TR1 | 410~570 | ≥265 | ≥21 | / | |

P265TR2 | 410~570 | ≥265 | ≥21 | ≥40 | |

EN 10216-2 | P195GH | 320~440 | ≥195 | ≥27 | ≥40 |

P235GH | 360~500 | ≥235 | ≥25 | ≥40 | |

P265GH | 410~570 | ≥265 | ≥23 | ≥40 | |

13CrMo4-5 | 440~590 | ≥290 | ≥22 | ≥40 | |

10CrMo9-10 | 480~630 | ≥280 | ≥22 | ≥40 |

SPECIAL SERVICES

COMPANY ADVANTAGES