Seamless ASTM A210 medium-carbon boiler and superheater tubes

600.0~1200.0 USD

| Min. Order: | 10 ton |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 400000 tons/year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Pipe, ASTM A106 ASTM A53 Gr.B, API 5L X70 Carbon Seamless Pipes X60 X52 X42, API 5L X80 PSL1/PSL2 SMLS LINE PIPES, API 5L PSL2 X56 X60 SEAMLESS SMLS LINE PIPE |

Product Detail

| Model No.: | Seamless ASTM A210 |

|---|---|

| Means of Transport: | Ocean, Air |

| Type: | Seamless ASTM A210 |

| Grade: | A1,C |

| Certificate: | API 5L ISO9001 EU PED-97-23-EC CPD-93/68/EEC |

| Brand: | QCCO |

| OD: | 21.3-914.4mm |

| WT: | 2.77-59mm |

| Production Capacity: | 400000 tons/year |

| Packing: | coating, caps and in bundles |

| Delivery Date: | 15~45days after the first payment |

Product Description

seamless medium-carbon boiler and superheater tubes

Seamless Medium-Carbon Steel Boiler and Superheater Tubes

Detailed Description:

Seamless Medium-Carbon Steel Boiler and Superheater Tubes

Standard: ASTM A210/A210M (ASME SA210/SA210M)

Size:(mm)

Out Dimensions:21.3-914.4

Wall Thickness:2.77-59

Length: Fixed(6m,9m,12m) or normal length(5-12m)

Application:

It is used for boiler and boiler flue tubes. Including safe end, vault and supporting tube and super heater min wall thickness seamless medium--carbon steel tube

Steel Grde:

Grade A-1; Grade C

Packing:

Beveled/black painting/ plastic caps/ in bundles/ steel strips/ wooden protection

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength, Yield Strength,Elongation, Flaring, Flattening, Bending, Hardness, Impact Test),Surface and Dimension Test,Nodestructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

Mark:

As requested.

Chemical Compositions(%)

Mechanical Properties

Our company covers an area of 150,000 m2 with a total assets of 250 million Yuan. There are 360 staff members including 80 technicians in our company. We also establish an effective complete quality control system. In 2006,our company obtained the certificate of ISO9001 Quality System Authentification, Certificate of the EU PED-97-23-EC Quality Management System in 2008 and it started to run in accordance with API 5L in 2009,passed CPD-93/68/EEC certificate in 2011.

ASTM A210/A210M Seamless Medium-Carbon Steel Boiler Tubes

Seamless Medium-Carbon Steel Boiler and Superheater Tubes

Detailed Description:

Seamless Medium-Carbon Steel Boiler and Superheater Tubes

Standard: ASTM A210/A210M (ASME SA210/SA210M)

Size:(mm)

Out Dimensions:21.3-914.4

Wall Thickness:2.77-59

Length: Fixed(6m,9m,12m) or normal length(5-12m)

Application:

It is used for boiler and boiler flue tubes. Including safe end, vault and supporting tube and super heater min wall thickness seamless medium--carbon steel tube

Steel Grde:

Grade A-1; Grade C

Packing:

Beveled/black painting/ plastic caps/ in bundles/ steel strips/ wooden protection

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength, Yield Strength,Elongation, Flaring, Flattening, Bending, Hardness, Impact Test),Surface and Dimension Test,Nodestructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

Mark:

As requested.

Chemical Compositions(%)

C | Si | Mn | P | S | Cr | Mo | Cu | Ni | V | |

A-1 | ≤0.27 | ≥0.10 | ≤0.93 | ≤0.035 | ≤0.035 | / | / | / | / | / |

C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | / | / | / | / | / |

Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) |

A-1 | ≥255 | ≥415 | 30 |

C | ≥275 | ≥485 | 30 |

About us:

Cangzhou Qiancheng Steel-Pipe Co., Ltd. is located on the Industrial Zone, YanshanCounty,Hebei Province. It is one of the largest enterprises that specialize in producing and selling steel pipes and pipe fittings in North China. It is of convenient transportation as it is only 200 km away from Xingang, Tianjin, China.

Our company covers an area of 150,000 m2 with a total assets of 250 million Yuan. There are 360 staff members including 80 technicians in our company. We also establish an effective complete quality control system. In 2006,our company obtained the certificate of ISO9001 Quality System Authentification, Certificate of the EU PED-97-23-EC Quality Management System in 2008 and it started to run in accordance with API 5L in 2009,passed CPD-93/68/EEC certificate in 2011.

Our company is equipped with sophisticated manufacturing and testing equipments, and a complete testing system has been established which includes advanced testing equipments, such as X-ray detector, ultrasonic wave detector, hydrostatic tester, tension tester, metallurgical analyzer and physical & chemical lab, etc. These equipments and technologies guarantee that the production and testing processes are up to relevant standards, so that the products are satisfied by the requirements of clients doubtlessly.

Our products mainly include seamless steel pipe, hot-finished steel pipe, stainless steel pipe, pipe fittings, flange and supporting tubing, etc. Those products are not only sold to domestic large-scale enterprises, such as thermal power plant, chemical plant and power engineering, but also exported to USA, Italy, Germany, Malaysia, Thailand, South Korea, Kuwait, Czech, Indonesia, Hong Kong, India, Iran, Singapore and other countries and regions.

With powerful financial strength, advanced managerial concept, excellent marketing service, strict quality control system and the whole scientific method, we would like to develop together with you hand in hand. Adhering to the operation principle of "Faith First, Clients Uppermost", we will return you with high-quality products and complete after-sale service with the lowest price. We sincerely hope to establish long-term cooperation relationship with you on the basis of mutual benefit, reciprocity and common development!

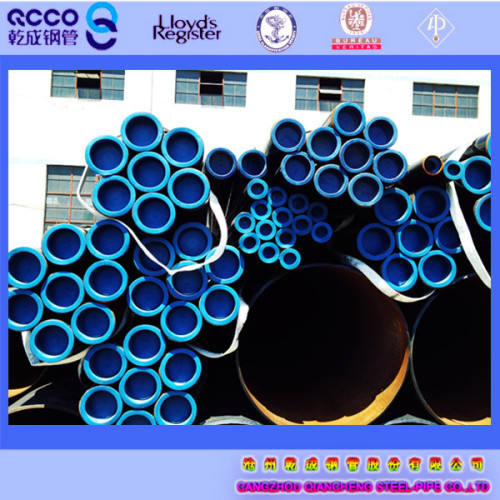

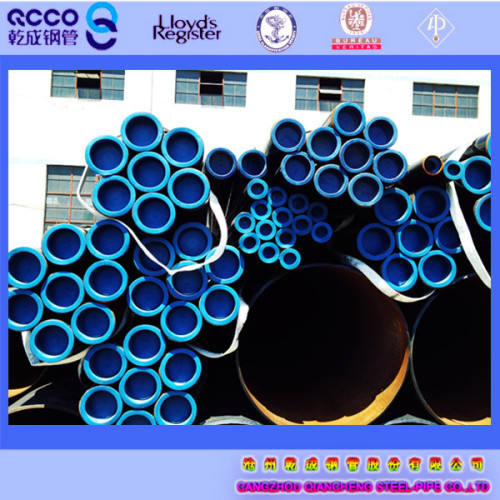

Products Photos:

Products Photos: