"krrass"- Hydraulic Shearer with Swing Beam QC12Y-16x4000

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000 |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nanjing, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | KRRASS |

| Production Capacity: | 2000 |

| Packing: | custmerized |

| Delivery Date: | 15days |

Product Description

Quick Details

Quick Details

Condition: New Place of Origin: Anhui, China (Mainland) Brand Name: AccurL Model Number: WC67Y-100T/2500 Machine Type: Press Brake Raw Material: Sheet / Plate Rolling Material / Metal Processed: Stainless Steel Power: Hydraulic Automation: Automatic Extra Services: Cut To Length Certification: CE After-sales Service Provided: Engineers available to service machinery overseas Bending Capacity: 100 Tons Bending Thickness: 6mm Length of Table: 2500mm Distance between Housings: 1950mm Throat Depth: 300mm Ram Stroke: 150mm Max open height between table and slider: 400mm Main Motor: 7.5 KW Dimension (LXWXH): 2560*1800*2550mm Weight: 6150kgs Packaging & Delivery

Packaging Details: Wooden Case

Delivery Detail: 15 days

Specifications

1.Press Brake Machine

2.CE,ISO,CQC Certification

3.BOSCH Hydraulic system

4.High performance

5.High quality with good price

The whole structure of the hydraulic press brake:

1.Totally European design, streamlined looking,Monoblock,Welded steel frame rigid to deflection moment and high tensile with ST44 A1 material.

2.AccruL PRESS BRAKE incorporates ESTUN E10 NC controls offer not only failsafe operation of the vital operations of the machine,but also offer the operator considerable assistance in carrying out the entire bending process.

3.High accuracy,high efficiency,simple and convenient operation,good performance, favorable price and best service.

1. Hydraulic system:

1. Adopt integrated hydraulic control system, more reliable and easy for maintenance.Hydraulic system is from Bosch – Rexroth,Germany.

2.Extremely reliable and precise Bosch – Rexroth valves are used for the regulating circuit. Every complete working cycle can be achieved through the control of hydraulic valve.

3.Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly.

Being able to work under rated load continuously,stable working and high precision.

4 All seals in cylinder is PARKER from USA,the most famous brand,good quality and high performance

2. Electrical system and the safety interlock:

1.Electrical panel with cooling system designed to meet CE Standards and composed of automation and electrical equipments with SIEMENS brand.

2.Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

3.Front Side Covers with safety switches, Back light safety guards (Category-4),Foot pedal conforming to CE regulation.

4. The machine by the European Union CE certification and ISO quality system certification

3. Synchro control system:

1. Slide synchro system:adopt steel torsion bar synchro system, simple in structure and high in accuracy,ensures the parallelism between beams is used for the synchronism

2. ends of slide has 2 synchro fork which make,The system uses upper die compensation to improve the brake precision.

3.The worktable adopts the particular design,reducing the crowning distortion amount of lower tool effectively.

4. Bending depth adjustment and RAM structures:

1. The bending accuracy and consistency of the repeatability are achieved by a simple mechanical system of adjustable depth Automatic (digit readout) and motorized (Estun E10 NC Control) Adjustable.

2. Can move the ram up slowly,which allows the operator to control work piece conveniently.

3. Universal fixing-surface of the upper tool can be meeting with the clamping requirement of the tool farthest.

4. Hardened and ground standard sectioned top and 4V-Die bottom tools (4x1000 mm sections).

5. Servo motorized Backgauge (standard)

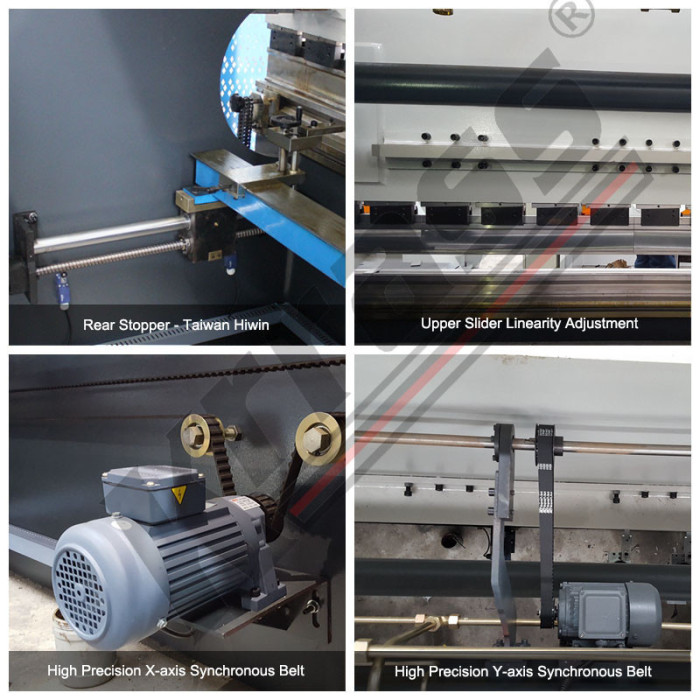

1. CNC Back gauge system with X axis by AC servo motor driven ball screw shafts and on linear bearings with an accuracy of 0.01mm.

2. Back gauge has well enough mechanical strength and rigidity with tank-type gauge structure.

3. High-precision ball screw and linear guide-way.Particular finger-stop design,enlarge the range of back gauge