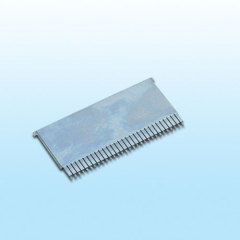

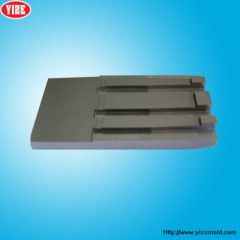

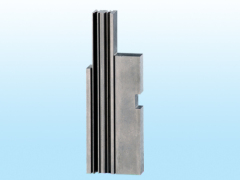

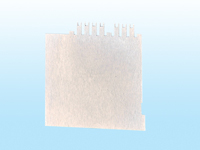

2014 low price injected plastic part

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 8000000 |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Plastic Injection Parts, Cnc Machining, Prototype, Moulded Design, Ect. |

Product Detail

| Model No.: | Karo-M55 |

|---|---|

| Means of Transport: | according to customers' requirment, Ocean, Air, Land |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | Customized |

| Color: | Any colors |

| Material: | PP,PS,PC,ABS,PMMA,etc. |

| Surface finish: | Chrome plating,gold plating,silver plating,silk-printing,painting,texture etc. |

| OEM/ODM: | Welcome |

| Feature: | Eco-friendly,etc. |

| Main Market: | Europe,America,worldwide,etc. |

| Production Capacity: | 8000000 |

| Packing: | Export carton or according to customers' requirment |

| Delivery Date: | 20-25 days |

Product Description

2014 low price injected plastic part | |

Company Profile: | We specilizes in developing and producing plastic injection parts and injection moulds for electrical appliances,home appliances,computers,telecommunication devices,pharmaceutical appliances, bathroom accessories and building plastic parts etc.We have a complete in-house manufacturing system - from tooling (die) design,making,testing to parts pressing and assembly. |

Key Specifications: | 1.Material:ABS,flame-retardant ABS,HIPS,flame-retardant,PS,HDPE,PMMA,PC,PVC,PP,TPR and TPU. 2.Surface Finish:Chrome plating,gold plating,silver plating,silk-printing,painting,texture etc. 3.Application:electrical appliances,home appliances,telecommunication devices,bathroom accessories, pharmaceutical appliances,building and outdoors etc. 4.OEM/ODM are welcome. 5.The photo of product shown here is for reference purposes only. |

Competitive Advantages: | 1.Can offer total solutions to customer's idea with in-house production/assembly and outsourcing program. 2.Can offer engineer consultation to customized designs for production improvement and cost saving. 3.Strict QC is enforced at all stages. 4.In-house tooling design and manufacturing. 5.Good experience on developing designs according to customer's requirements. 6.Flexible manufacturing quantities. 7.Advanced CAD,CAM and CAE technology. |